- Discover track and trace

- Product platforms

- UHF (Ultra-high frequency) RFID systems

- Gate tracking solution

Gate tracking: Wireless automated tracking solutions

The challenge

Studies show the average error rate during order picking and shipment is between 0.3% and 3%. Average product loss and freight cost can easily exceed $100,000+ annually. So why are companies still using a manual process to track and verify raw materials and shipments?

| "UHF product tracking is complex." | ...everything new seems complex. |

| "UHF tracking is expensive." | ...well, it used to be. |

| "I tried UHF 10 years ago, it doesn’t work." | ...technology improves. |

| "I will never see a return of the investment." | ...now you will. |

What if you could find a gate or conveyor tracking solution that was inexpensive, simple, and could be up and running in days or weeks without months of both software and hardware development?

Rather than equipment, the barrier for companies instituting an automatic gate tracking program has been the severe cost and complexity of software integration and the creation of actionable data from installed hardware. In many cases, the software development and implementation far exceeds the hardware cost, limiting the financial feasibility of a useful tracking program.

Capability is another barrier. Simple triggering mechanisms provide inaccurate or incomplete data on the direction of movement, and UHF field reliability in older equipment designs provides dead zones and error in the tracking process.

The wireless and automatic tracking of UHF-tagged assets, combined with directionality and direct connection to the IT layer offers a solution that addresses your concerns - allowing you to optimize loading times, avoid picking errors, improve returnable asset tracking, and increase efficiency in your facility.

The solution

Using our continued growth in UHF deployment, our knowledge in RFID technologies, and continued developments in connectivity and edge processing, ifm developed a tracking solution to address common challenges to successful system deployments.

Triggering direction detection with 3D Time-of-Flight environment mapping offering volumetric muting and directionality, all standard.

Edge-control and pre-processing allows for immediate triggering and formatting, increasing data accuracy and eliminating network reliance for data capture.

All hardware included in the solution is IP65/IP67 and can be mounted directly to a wall or support structure.

Standardized JSON message structure of gate events. All equipment control handled at the edge with included software solution.

Solution software is pre-installed on the master edge controller and is configured on device with a multi-point touch screen.

The hardware

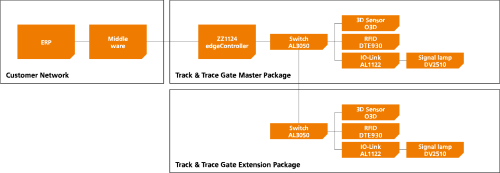

The gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

Hardware topology

The system’s multi-touch edge controller provides intuitive configuration and point-of-use diagnostics. A single controller can support up to 10 tracking gate systems, allowing for real time display of errors, and on-the-fly shipment adjustments. A simple, easy-to-use configuration wizard will have systems communicating in 15 minutes.

The integration

Why should you spend time in developing software for a control tracking "solution"? We believe you should be concerned with using your information, not the data and hardware handling.

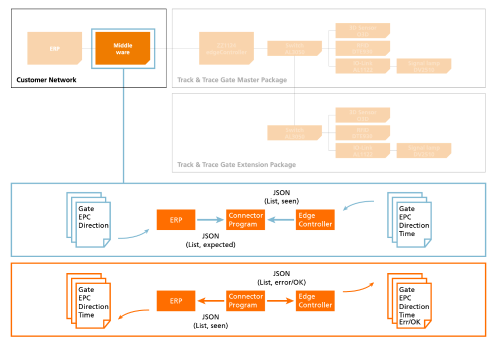

We believe you should spend time where it makes sense - in the simple, direct, connection to your existing ERP or MES system. By offering platform independence, the ifm solution adapts to your existing software structure and offers reliable tracking data.

- Standard JSON formatted messaging enables simple communication and information handling

- Easily integrated withy any ERP/MES through a simple connector program, or "comparison of lists"

- Set

- Subsequent equipment is configured with templates and intuitive software indepenent of gateway controller

- Native JSON messag

The only thing you need to decide is how to apply the information provided. The information is available through a universal JSON structure. A middle-ware “connector” program provides a condition-based comparison of exported lists.

Connector middle-ware program links the edge controller to yourr ERP system

JSON syntax for connector program

| To Edge Controller | [{“eventID”:5,”gateID”:490502,”direction”:”OUT”, “EPC”:”E2801114200087CB77001234E21F2021000000000002AD5F”,”TID”:””,”user”:””,”timestamp”:”2021-03-15T13:14:30+0100”}] |

| From Edge Controller | [{“eventID”:6,”gateID”:490512,”direction”:”OUT”, “EPC”:”E2801114200087CB77009876”,”TID”:”E21F2021000000000001767B”,”user”:””,”timestamp”:”2021-03-15T13:14:30+0100”,”result”:”ERROR”}] |

The benefit

A complete automation of raw material reception, sequencing, and shipment verification doesn’t only offer a savings in fees or shipment costs to correct a missed order.

Automation of these areas:

Consider redirecting the accumulated time of no longer physically scanning or visually verifying. Easily freeing up funds for additional production personnel.

Eliminate costs associated with short or over-shipments and/or fines and rejected shipments. Eliminate the cost of return and replacement shipments.

Develop trust and become a reliable and accurate supplier of finished goods for expansion of your business.

Eliminate printers and paper - wirelessly update item level information with RFID technology.

Shipments are accurate the first time, eliminating re-runs and freeing up production capacity.

Calculable amortization is normally under 1-2 years for a full tracking system, which takes into account the cost of individual item level UHF tagging

ROI calculator

ifm invites you to explore the possibilities by calculating your own system's payback period. Keep in mind that these numbers only account for calculable expenditure, and are usually realized in 1/2 the projected timeframe.

The support

As a global controls solution provider, free application and technical support is just a phone call away, any time you need us. Our service center is staffed from 7:30 am to 6:30 pm Eastern Time to cover all US time zones.

800-441-8246

It’s our goal to respond to your emails in 15 minutes. Your time is valuable!