- Discover track and trace

- Solutions

- Packaging and unitizing

Packaging and unitizing: Accurate product packaging and shipping

Automating quality control and intra-logistics

Ensuring the correct packaging is used for your product is a critical control point for any robust quality monitoring program. Filling stations, bottling lines, and everything through end-of-use packaging must match the product they contain.

Unique identifiers on individual products are then combined into a bulk package for shipment, and must not only match the order precisely, but allow for traceability for minimized recall or rework lot sizes. Once an identifier is recorded for a bulk/unitized pallet, this identifier can be leveraged for shipment and sequencing verification in fulfillment.

Realized improvements in operating efficiencies

Identifiers first serve as initial quality control checks for mixed lot prevention on individual products. When applied, identifiers on individual units can be sequentially tracked with a single unitized identifier for shipment and logistics purposes. Increasing not only the quality of the finished good, but improving processing speed and accuracy of product shipments.

- Initiate a robust mixed lot prevention program

- Minimize lot sizes for product recall and rework

- Ensure every shipment is correct with manifest and sequencing verification

- Broaden intra-logistics capabilities for reduced order sourcing time

Recommended product platforms

Many technologies can be applied to packaging and unitizing, however UHF RFID platforms are typically most effective for bulk identification to unlock further capabilities with intra-logistics and logistics management.

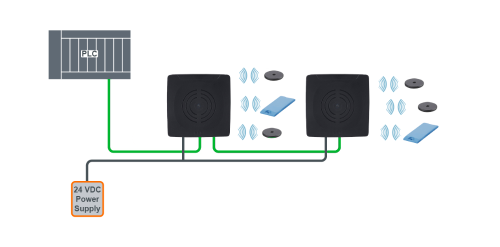

Unitization often relies of two distinct classes of technologies. At the item level, image-based code reading is commonly used because of the high volume of identifiers needed, or for applications with unchanging information (mixed lot prevention). Based upon your specific processes in the facility, it is possible to apply HF RFID to this stage in the process.

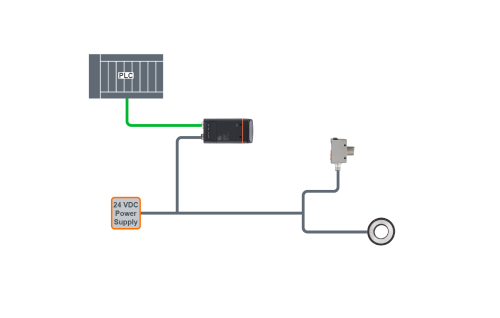

Image-based code reading system

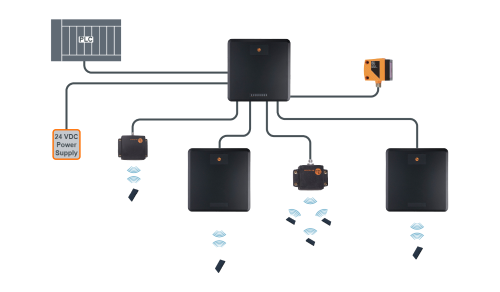

Once the units are unitized, longer ranges are needed for tracking in logistics and intra-logistics for manipulation by forklifts with mobile automation and perimeter control gateways for shipment sequencing. In many cases, the preferred solution is UHF RFID for tracking in logistics due to memory that can be manipulated, as well as low cost application to a shipment unit ($0.08).

Modular UHF system

For applications requiring only a single read point per physical location, the All-in-One UHF system offers simple integration of UHF technology with little or no impact of existing network architectures. This is often the ideal solution for hand manipulated in-process transfer carts, hi/lo movement of bulk material binds and sacks, and large item deliveries and shipments of raw materials requiring a bulk read of 16 tags or less and a range of 4 m or less.

All-in-one UHF system

In some cases, UHF RFID is a proper solution across the board for monitoring in that it can be applied on the production line, through the packaging and unitizing process, and bulk read for automatic shipment manifest creation and sequencing at the dock door.

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 | Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Packaging and unitizing | +++ | +++ | ++ |

Click on the orange links to view product platforms