- Discover track and trace

- Solutions

- Raw materials management

Raw material inventory management software

Raw material inventory management software is a critical tool for optimizing manufacturing efficiency and supply chain operations. It streamlines the tracking and management of raw materials using advanced technologies like RFID, ensuring continuous production and reduced operational losses. This page covers:

- Key features and benefits of raw material inventory management software.

- Advanced tracking technologies like RFID for efficient inventory management.

- Impact on operating efficiency and reduction in manufacturing losses.

- Detailed exploration of product platforms and tracking solutions.

Maintain accurate inventories, minimize lot sizes, and increase production availability

Tracking technologies applied to raw material storage and retrieval ensure that production never stops. Item level serialization accurately tracks individual components/lots to minimize lot sizes, and location data ensures that production runs without interruption. This strategy extends to tracking returnable assets through deliveries of raw materials and other shipments.

Automating logistics and intra-logistics

RFID technology enables automatic and reliable raw material location tracking and real-time inventory management. Tie physical shelf or storage locations to serialized assets, apply RFID scanning portals to bounded storage areas, or use mobile RFID automation on a forklift fleet to unlock material localization in unstructured environments.

Realized improvements in operating efficiency

Time spent on production set-up adjustments and material sourcing accumulates over time, and together they represent one of the Six Big Losses in manufacturing.

Instituting a robust raw material tracking program is the first step to ensuring that your production avoids unnecessary stops. By maintaining a real-time inventory of serializes and traceable raw materials with location data, you:

- Always have raw materials in stock and available for use

- Reduce sourcing time for needed materials

- Eliminate time spent on machine set up for unavailable product

- Maintain supply chain integrity

- Reduce recall lot sizes, eliminating rework and reruns

Recommended product platforms

In order to ensure that the information maintained in a robust raw materials management system is accurate over time, it is important that the system operate automatically.

To achieve an automatic system capable of long range wireless communication of tracking data without requiring a line of sight, investigate UHF RFID technology as a new tracking program. Some cases, such as the automation of an AGV (automated guided vehicle) or ASRS (automated storage and retrieval system), may be suitable for shorter range identification technologies.

Modular UHF system

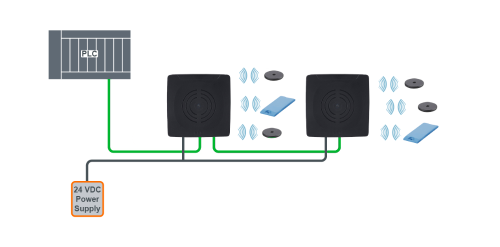

For applications requiring only a single read point per physical location, the All-in-one UHF system offers simple integration of UHF technology with little or no impact of existing network architectures. This is often the ideal solution for hand manipulated in-process transfer carts, hi/lo movement of bulk material bins and sacks, and large item deliveries and shipments of raw materials requiring a bulk read of 16 tags or less and a range of 4 m or less.

All-in-one UHF system

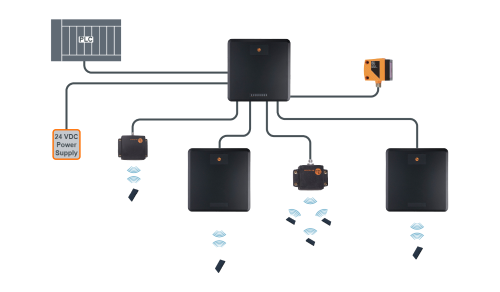

The UHF gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

Gate tracking solution

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 |

Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Raw materials management | + | ++ | +++ | +++ | +++ |

Click on the orange links to view product platforms