- Discover track and trace

- Solutions

- WIP management

WIP management with track and trace (TTQ) solutions

WIP management: Effective, lean and intelligent production

WIP management solutions optimize production efficiency by providing real-time work-in-progress insights. This article explores integrating WIP tracking with MES systems and employing digital twin technology. Read more about:

- Automating intra-logistics and production

- Realized improvements in operating efficiaences

- Recommended product platforms

Automating intra-logistics and production

Tracking work-in-progress (WIP) gives real-time insight of what is in production, giving the ability to create a digital twin of the production floor. This information allows MES systems to optimize production scheduling based on availability of raw materials, sub-assemblies and machines. Identifiers are applied to the carriers on the closed loop production line. The workpieces are encoded with identifiers used to track the products throughout the production processes. All production data is recorded with each product for complete production traceability.

Realized improvements in operating efficiencies

Work pieces in progress are problematic. With an ever-changing supply of partially complete assemblies, it can be challenging to maintain an accurate inventory available for production, while optimizing production in a fluid environment can be troublesome.

The first step in automating WIP flow through production is serialization of workpieces and carriers. After a real-time inventory system is established for what components or sub-assemblies are available for production, production runs and changeovers can be optimized. Perhaps a production change exists that would require only one tool change as opposed to twenty. Perhaps your operators run faster with higher quality if minimal changes to production runs take place throughout the day.

Increases in availability are realized through a creation of an accurate inventory of sub-assemblies in progress and the use of a digital factory clone. Ensuring that required sub-assemblies are available eliminate material shortages, and optimization of production changes will significantly reduce time required for setup and changeover.

- Fewer small stops and unplanned stops due to insufficient material

- Improved shop floor visibility

Increases in performance are realized through optimization of operator efficiencies, in addition to a significant reduction in small stops created by constant large-scale production changeovers.

- Enhanced production scheduling and synchronization from step to step

- Digital connection of production to machine / process control

Recommended product platforms

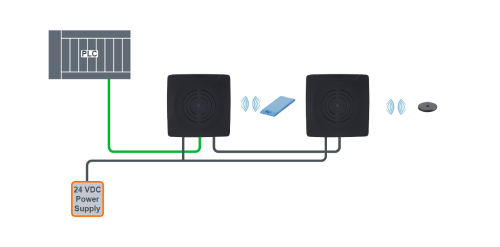

Many different identification technologies can be deemed appropriate for WIP management in production. Most solutions will rely on either HF RFID technology or image-based code reading to ensure that a identifier/workpiece is isolated (no cross reading possible).

The solutions are also useful for other track and trace applications such as the tracking of returnable assets.

Many WIP solutions require a significant amount of data stored locally on the workpiece, so an identification solution designed to transfer large payloads quickly is an ideal choice.

Modular HF system

All-in-one HF system

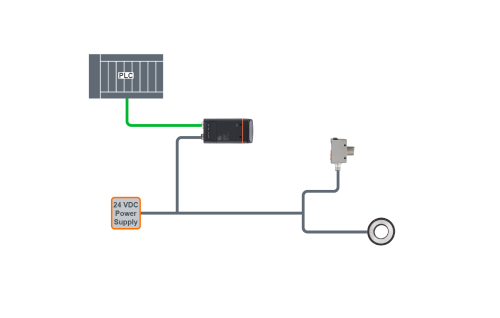

If the environment is not extremely harsh, an image-based code reading solution may be appropriate.

Image-based code reading system

If a WIP solution is designed to utilize only a small amount of data, or the process is not high speed, IO-link HF RFID can be a viable solution for WIP management as well, while allowing additional process information to be communicated to the controller over IO-link for further optimization of production.

The gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

Gate tracking solution

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 |

Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| WIP management | ++ | +++ | +++ | ++ | ++ | +++ | ++ |

Click on the orange links to view product platforms