- Discover track and trace

- Solutions

- Sequencing and shipments

Track and trace: Sequencing and shipments

Automating logistics

The dock door is, in many cases, the area of a production facility most primed for tracking automation, since all raw materials and finished good pass through these doors. Serialization of shipping units, along with returnable asset management, unlock the capability of ensuring that every order is complete, and is sequenced correctly for JIT manufacturing when staged and loaded onto a truck in fulfillment.

Within any production facility, an incorrect shipment can cost significant production time for rework or reruns of product lost or needing to be fulfilled in a timely manner. These issues are compounded in JIT manufacturing where a producer can face exorbitant fines for late/incorrect deliveries, or deliveries out of sequence.

Realized improvements in operating efficiencies

UHF technology allows for low cost solutions for sequencing verification of goods in JIT manufacturing, as well as monitoring the loading of the truck to ensure accurate shipments and chain of custody of finished goods and materials. Extremely low cost UHF-enabled labels can be applied to nearly any finished good for shipment verification and perimeter control.

Increases in performance are realized through the automation of the shipment process and automatic sequencing verification. Automated logistics systems not only decrease the time spent sourcing and sequencing the product for shipment, but the eliminate the need for re-runs on production to meet a deadline.

- Reduce time spent verifying sequencing of products

- Eliminate over production and re-runs on the production lines

Increases in quality are realized through automating the correct delivery of a complete order, in the correct sequence, every time. Automated manifest creation allows for custody chain integrity of shipments for traceability.

- Eliminate incorrect or incomplete shipments

- Eliminate sequencing errors in shipments

- Show a clear chain of ownership of produced products

Recommended product platforms

In almost all cases, the technology of choice for the automation of sequencing and shipments is the modular UHF RFID platform, offering a full portfolio of antennas for creating an adaptable platform that can be suited to your logistics process for tracking and sequencing shipments.

Modular UHF RFID system

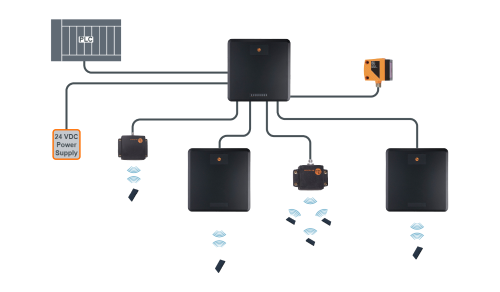

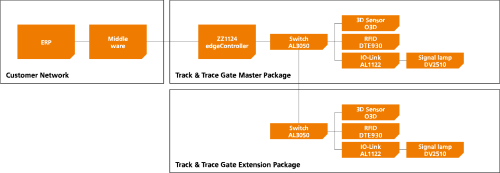

The UHF gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

Gate tracking system

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking system ZZ0818 |

Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Sequencing and shipments | +++ | ++ | +++ |

Click on the orange links to view product platform