- Discover track and trace

- Solutions

- Returnable asset management

Returnable asset track and trace solutions

Returnable asset items such as pallets, bins, and custom transportation frames minimize waste and reduce packaging costs through repeated use. But, you must manage and maintain these items to achieve that ROI. By automating and streamlining your returnable asset management, ifm’s track and trace solutions help you:

- Enhance efficiency

- Improve supply chain sustainability

- Reduce expenses

Returnable asset tracking technology

Returnable asset tracking technology from ifm lets you locate returanable assets in real-time, validate returnables and establish lean logistics operations. We provide:

- Long-range communication for out-of-sight assets

- Short-range communication for automated tools and systems

- Effortless integration for single read points

- Gate tracking and cloud technology for comprehensive tracking

The result is a comprehensive system to track returnable assets throughout their chains of custody. You can establish lean logistics operations by locating assets in real-time and validating returnables.

Automating logistics and intra-logistics

Transport containers are essential to keeping product protected in transit and managing the supply chain. Containers are used for transporting a multitude of goods such as: beer, syrup, gases, automotive sub-assemblies, chemicals, etc. Containers can cost from $400 to $10000 each and there can be thousands in service at any one time. Manufacturers of products that are transported in these containers cannot lose sight of their assets, since an inadequate supply of containers disrupts the supply chain, costing millions in losses.

Realized improvements in operating efficiencies

UHF RFID technology helps to keep track of these reusable assets. RFID tags are applied to the containers with an identifier. As the containers travel out of shipping docks and through receiving docks, the WMS is updated in real-time aiding in improving the logistics operations. The logistics manager knows where every asset is in real-time.

- Improve supply chain management

- Reduce logistics operational costs

- Provide real-time asset tracking

Recommended product platforms

In order to ensure that the information maintained in a robust returnable asset management system is accurate over time, it is important that the system operate automatically.

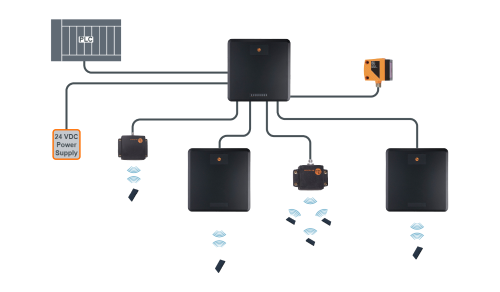

Modular UHF system

To achieve an automatic system capable of long range wireless communication of tracking data without requiring a line of sight, investigate UHF RFID technology as a new tracking program. Some cases, such as the automation of an AGV (automated guided vehicle) or ASRS (automated storage and retrieval system), may be suitable for shorter range identification technologies.

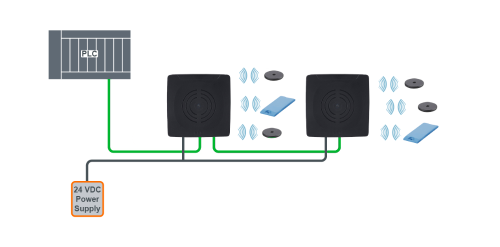

All-in-one UHF system

For applications requiring only a single read point per physical location, the All-in-one UHF system offers simple integration of UHF technology with little or no impact of existing network architectures. This is often the ideal solution for hand manipulated in-process transfer carts, hi/lo movement of bulk material bins and sacks, and large item deliveries and shipments of raw materials requiring a bulk read of 16 tags or less and a range of 4 m or less.

Gate tracking system

The UHF gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

| Track and trace solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 |

Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Returnable asset management | + | ++ | +++ | +++ | +++ |

Click on the orange links to view product platforms