- Discover track and trace

- Solutions

- Storage and retrieval

Storage & retrieval: Track inventory and finished goods in real time

Automating intra-logistics

UHF RFID technology enables low cost, highly effective inventory tracking and localization capabilities. As a completely modular solution, storage locations and areas can be tracked with portal detection, or shelf locations can be monitored with mobile automation applied to forklifts. In unstructured storage environments, floor embedded RFID tags and mobile UHF equipment can monitor pick up and drop off locations in real time to record the locations of your assets and visually prompt the driver with locations of the next asset, or the next location drop off of the unit(s) that are being manipulated.

Realized improvements in operating efficiencies

Increases in operational efficiencies are not limited to the production line. Significant time can be lost attempting to locate a unit for shipment, and an ineffective storage and retrieval methodology and/or lack of returnable asset management strategy can result in over production, late deliveries, inaccurate shipments and significant cost to the bottom line.

Increases in performance are realized through management of real-time location-based inventory. Identifiers on finished goods are automatically scanned into storage bays to give general location data, while shelf locations can be tagged with identifiers to tie individual units to storage locations. Tracking in unstructured storage environments relies on a grid of location tags to localize the asset/pallet utilizing automation applied to mobile vehicles, AGVs, and/or human-operated forktrucks.

- Reduce sourcing time with localized, real-time inventory

- Eliminate time wasted locating a lost finished good

- Eliminate re-runs or production over-runs of lost product for fulfillment

Increases in quality are realized through proper sequencing and automatic order verifications. Workers are notified in real time if a unit picked up is out of sequence or incorrect. Shipment sequencing is verified again at the point of embarkment, and an automatically generated shipment manifest records the chain of custody of finished and shipped goods for fulfillment.

- Eliminate incorrect pallet quantities and product mismatch

- Verify shipment sequencing for JIT manufacturing

Recommended product platforms

In most cases the best choice for intralogistics tracking will be the modular UHF platform, offering a full portfolio of antennas for creating an adaptable platform that fits everything from gateway portal tracking to localization in an unstructured storage environment.

UHF RFID system

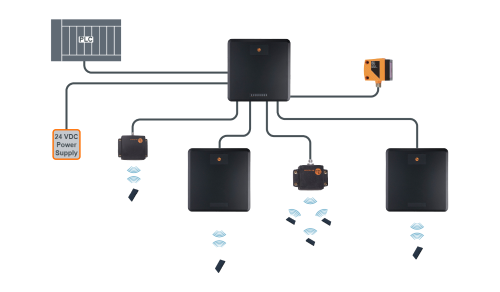

The gate tracking solution consists of all required hardware to activate a single tracking cell. Initially, a master gate enables northbound communication to any ERP system and/or cloud solution while handling the southbound control and configuration of up to 10 connected supplemental gates.

Gate tracking solution

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 |

Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Storage and retrieval | +++ | ++ | +++ |