- Discover track and trace

- Solutions

- Smart tooling

Smart tooling with track and trace (TTQ) technology

Smart tooling: The right tool for the right operation at the right time

Identify the right tool for the right operation at the right time. Smart tooling and track and trace (TTQ) technologies ensure that the right tool is used for the right operation at the right time, while providing real-time tracking and data analysis to optimize tool life and operational efficiency.

This article covers:

-

Automating intra-logistics, maintenance and quality control

-

Realized improvements in operating efficiencies

-

Recommended product platforms

Automating intra-logistics, maintenance and quality control

Tracking technology enables smart tooling within production. Tools can report what and where they are, how many cycles or hours they have been in production, and retain operational condition data for trending tool life (max temperatures, misalignment conditions, etc.). Machine configurations are automated by identifying the correct tooling for the operation. RFID tags are applied to tools and are encoded with an identifier for tracking tool data.

Localization of tooling in real-time is essential for large production operations. In stamping or injection molding operations, the dies or molds get transported from machine to machine, in and out of warehousing areas, and to/from maintenance stations. UHF RFID tags including the tool identifier are applied directly on the tools. Data about the tool is recorded such as cycle counts, last service date, and last known location. As the tool is used in production, the cycle counts adjust accordingly. Once tools are changed and move to other machines or storage locations the system updates in real-time with this essential data. Now at any given time a tool can be tracked and the life of the tool is traceable.

Realized improvements in operating efficiencies

Through the serialization of tools for manufacture, a facility allows for enhanced localization and smart manufacturing practices that address productivity losses across many areas of manufacturing.

Increases in availability

Increases in availability are realized through advancement in smart manufacturing practices regarding enhanced automatic machine set-up capabilities and tool localization. This allows for advanced crash mitigation and a drastic reduction in changeover times.

- Locate tooling in real time

- Automate planned stops

- Mitigate downtime due to incorrect tooling

Similiar benefits are achievable using track and trace tools for the management of returnable assets.

Increases in quality

Increases in quality are realized through automating machine setup processes and initiating robust preventative maintenance schedules on tooling with regards to actual time used in part manufacture.

- Reduce start up rejects

- Track number of cycles / cycle time

- Alert and automate maintenance scheduling from machine to CMMS

Recommended product platforms

In most cases, smart tooling solutions require the tool be read wirelessly and the information stored within the identifier be writable. This ability to manipulate data is important to store both maintenance schedules and cycles run on the tool component.

In almost all cases, the tool is identified at short range in a metal-laden environment requiring isolation from other tags in its proximity, and the need for simplicity of integration is paramount.

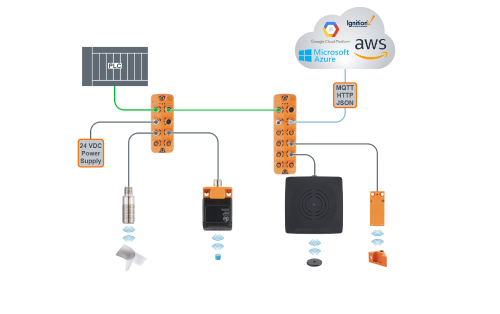

IO-Link HF system

For these reasons, the HF IO-link platform is recommended for smart tooling applications. To unlock localization within your facility, UHF RFID may be required to allow for longer read ranges, where AGV (automated guided vehicles) and ASRS (automated storage and retrieval systems) are not present. For high data transfer rates (not common in smart tooling), other HF RFID platforms are recommended.

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 | Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Smart tooling | +++ | ++ | ++ | + |

Click on the orange links to view product platforms