- Discover track and trace

- Solutions

- Error proofing

Track and trace: Error proofing solutions

Error-proofing with track and trace (TTQ) solutions

Ensure every product is made to specification with zero mistakes leaving production -- Batch of One (Flexible Manufacturing). Error-proofing in track and trace solutions is pivotal for automating quality control. These technologies enhance the efficiency of production processes and significantly reduce the occurrence of defects.

By implementing such solutions, you can ensure adherence to quality standards, streamline production, and minimize the costs associated with repairs and wastage.

Automating quality control

Error proofing allows you to prevent mistakes from occurring in automated processes. It also allows you to identify production flaws so bad parts can be pulled for re-work or scrap, never leaving the factory. The sooner defects are identified within the production processes, the less expensive it is to fix or remove from production.

Cost of repair escalates further in the process

Identification technology enables manufacturing processes to proactively prevent errors from occurring. In the case of flexible manufacturing or batch of one production, identifiers applied to product carriers and each individual product is tracked through the production process. By identifying products through every production step, machine configurations and processes are carried out accurately as defined by the individual product, essentially a digital build instruction for machines. The quality inspection data is logged in the QMS for each product. At line diverters, or end-of-line, any failed products will be diverted for scrap or rework. This means quality assurance!

In Food and Beverage manufacturing, it is essential that the right connections are made to the right ports at flow panels for proper mixing and cleaning procedures. By applying unique identifiers to unions, the production control system can assure the flow panels are connected properly. Now there is 100% assurance that mixtures are right and processes are completed correctly.

Realized improvements in operating efficiencies

Serialization of components ensures local build instructions are available for quality checks throughout the build process for a batch of one. With local identifiers, a product can carry quarantine information, or instructions for rework prior to release to ensure that only product meeting every inspection step are available for shipment.

- Prevent errors in assembly process when the product provides build instructions to machines digitally

- Reduce production defects by ensuring machines are configured correctly for the product in process

- Zero defects make it outside of production by tracing every production step

- Enhance efficiency by managing returnable assets

Recommended product platforms

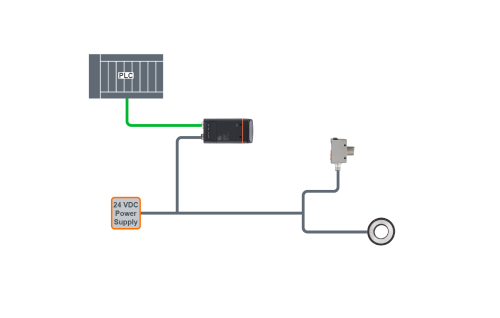

Many common error proofing applications today require high speed data transfer of the product identifier. This can, in many cases, require a large transfer of data over a short period of time. The Modular HF and All-in-one HF systems are optimized for efficient data transfer and are therefore recommended in most error proofing applications.

The Modular HF family also offers a robust read / write head portfolio for optimization of read fileds, and isolation of individual tags on the production line.

Modular HF system

If a unique, unchanging, dataset is to be used in a license plating application, image-based code reading offers a fast evaluation time, for transmission to a higher level control systems and can be considered for error proofing applications in flexible manufacturing.

Image-based code reading system

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 | Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Error proofing | ++ | +++ | ++ | + | + | +++ |

Click on the orange links to view product platforms