- Introduction to moneo

- Use cases

- Improve machine availability

Improve machine availability

Availability losses include unplanned stops, such as equipment failure, and planned stops, such as machine setup and recipe changeover time. The following simulations show examples of how moneo can help reduce unplanned stops.

| Machine | Description | Common falure modes | Watch video |

|---|---|---|---|

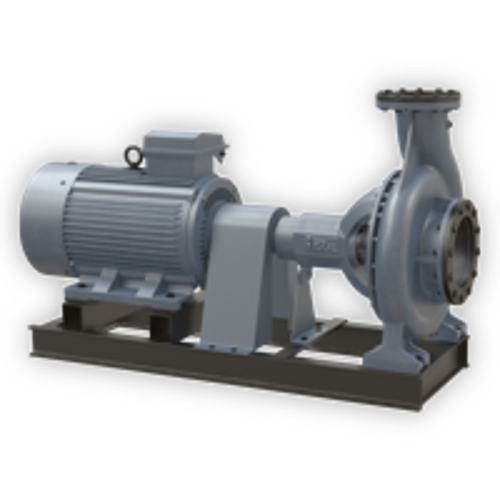

Centifugal pump |

ifm vibration and temperature sensors with moneo | software track the operating condition of the pump system in real time. |

Pump cavitation - destructive formation and collapse of bubbles in the fluid, typically due to suction restriction. Bearing failures - pitting, rubbing, etc. of rolling elements, inner race, or outer race. Bearing temperature - loss of lubrication liquid, loss of coolant flow, electrical issues, excessive load. Pump unbalance - fatigue, misalignment, loose footing, other structural issues. |

|

Ducted fan |

ifm vibration and temperature sensors with moneo | software track the operating condition of the fan system in real time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Fan unbalance - contaminates in the air stream collect on the fan blades causing unbalance of the rotating mass. Bearing failures - pitting, rubbing, etc. of rolling elements, inner race, or outer race. Bearing temperature - loss of lubrication liquid, loss of coolant flow, electrical issues, excessive load. Structural issues - fatigue, misalignment, loose footing, loose shafting, belt / sheeve issues. |

|

Heat exchanger |

ifm pressure, temeprature, and conductivity sensors with moneo | software track the operating condition of the heat exchanger in real-time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Fouling of shell and/or tubes - causes excessive system backpressure affecting the operation of other system components such as pumps and motors. Leakage between shell and tubes - compromises product quality or operation of downstream equipment. Reduction in energy efficiency - occurs due to fouling of thermal interfaces. |

|

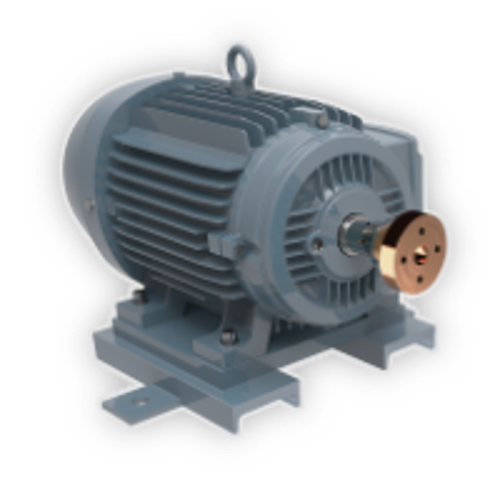

Electric induction motor Electric induction motor |

ifm vibration and temperature sensors with moneo | software track the operating condition of electric motors in real time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Motor unbalance - unbalanced loads of driven equipment overstress motor couplings and mounting fasteners. Bearing failures - pitting, rubbing, etc. of rolling elements, inner race, or outer race. Bearing temperature - loss of lubrication liquid, loss of coolant flow, electrical issues, excessive load. Structural issues - fatigue, misalignment, loose footing, loose shafting, belt / sheeve issues. Current consumption - excessive current draw overloads windings causing shorts and reduced energy efficiency. Loose / broken rotor bars - mechanical faults of the motor electromagnet system. |

|

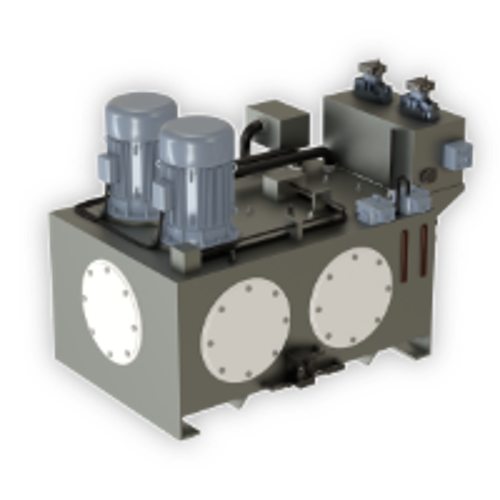

Hydraulic power unit Hydraulic power unit |

ifm vibration , flow, level, and temperature sensors with moneo | software track the operating condition of the HPU system in real time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Hydraulic fluid temperature- overheating of hydraulic fluid can damage pumps and driven devices. Seal wear - contaminants in hydraulic fluid and nomal wear and tear cause excessive pressure and flow loss. Mechanical wear - pump and driven mechanism wear introduce metal particles that compromise the complete system. Bearing failures - pitting, rubbing, etc. of rolling elements, inner race, or outer race. |

|

Centrifugal separator |

ifm vibration , pressure, flow, and temperature sensors with moneo | software track the operating condition of centrifugal separators in real time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Unbalanced loads - excessive sludge and scaling buildup cause plugging of disk stacks. Drive system wear - gear drvies, misalignment, loose footing, other structural issues. Bearing failures - pitting, rubbing, etc. of rolling elements, inner race, or outer race. Flow restrictions - feed and flush supply, and solids and phase discharge issues. |

|

Dry vacuum pump |

ifm vibration and current sensors with moneo | software track the operating condition of dry vacuum pumps in real time. The easy-to-implement moneo system alerts you to warning and alarm conditions, allowing you to repair the problem before catastrophic failure and unplanned downtime. |

Current monitoring – excessive current draw detects motor and mechanical issues of pump operation. Vibration monitoring – detects build-up of debris that causes excessive friction on close fitting rotors. Vibration monitoring – detects damaging impacts of ingested materials. Motor speed monitoring – detects excessive load on pump drive system. |