- moneo IIoT platform

- Software architecture

- moneo Industrial AI Assistant

Industrial AI Assistant in manufacturing improves OEE

Smart manufacturing techniques reduce downtime and increase product quality

When using Artificial Intelligence (AI) in industrial applications, relevant information is extracted from data for additional processing so that automated decisions and predictions can be made.

The Industrial AI Assistant (formerly known as moneo Data Science Toolbox) makes it easy for everyone to apply data science. This AI assistant offers various tools that you can use to optimize and monitor manufacturing processes - all without advanced knowledge of data science and programming.

Reliably monitor manufacturing processes

Simple

No data science expertise is necessary. Easy to implement for production and maintenance personnel.

Easy to train

Train your models quickly with a sample of normal operating data. No need to simulate or replicate fault conditions.

Guided configuration

Graphical template-based configurators use normal machine operating conditions to guide a user to select, test, and validate machine model performance.

Edge deployable

Compact edge algorithm models do not require powerful processors and memory, allowing processing close to the point of use.

Tunable

Fine-tune alerts as desired to optimize your preventive maintenance programs.

Reliable

Proven statistical models access both time-based and condition-based monitoring for prediction and advanced insights of changes to your equipment’s operational condition.

Industrial AI Assistant tools

The Industrial AI Assistant currently includes the software solutions moneo SmartLimitWatcher and moneo PatternMonitor which serve to detect anomalies.

Additional predictive maintenance tools are already in development and will soon be added to the Industrial AI Assistant.

moneo SmartLimitWatcher |

moneo PatternMonitor |

|

|---|---|---|

| Principle |

A mathematical model that predicts deviations of a system by evaluating the relation between its components, this is completed through the following simple steps: 1. Collect training data |

A statistical model that monitors operational changes of a critical process value over time, in any of these pattern types: 1. Volatility |

| Advantage |

|

|

| How? |

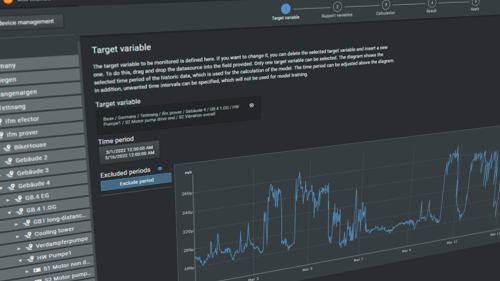

Actively evaluates the relation between the system’s key parameters (Target and Support variables), and compares it to the predicted target values. These dynamic thresholds provide the operator with insights to the machine’s performance under different operating conditions. |

Actively evaluates the primary process value for pattern changes, and provides indicators of slow wear (volatility and trends) or spontaneous breakdown events (step changes). These pattern changes alert the operator of changes in process quality or asset failure. |

| Implementation requirements | Knowledge of the system to select appropriate parameters:

|

Knowledge of the process to select the appropriate:

|

| Uses |

Improve machine availability of multi-stage or regulated systems, such as motors and separators. |

Improve process quality of stationary on / off processes. |

| ➜ Learn more about moneo SmartLimitWatcher | ➜ Learn more about moneo PatternMonitor |

SmartLimitWatcher (SLW)

PatternMonitor (PaM)

| Industrial AI Assistant | Traditional data science approach | ||

|---|---|---|---|

|

Easy-to-use tool, suitable for maintenance teams without data science skills |

Access to data scientists necessary (expensive, $20k+) |

||

|

Train models quickly with normal operation data |

Difficult to find or create fault conditions requires more time and resources |

||

| Automatic data preparation and AI training are incorporated | In-house project structure and management required | ||

| Integrated and scalable solution within the ifm moneo system | Complex data acquisition systems and software development necessary | ||

| Suitable for a wide range of applications with quick solution and results (2 - 4 weeks) | Minimum project duration approx. 6 - 12 months | ||

|

Excellent price-performance ratio |

Increased investment risk due to limited scalability |

||

| Customizable options in expert mode | Customized solutions are difficult to scale and roll out |