- Introduction to moneo

- Use cases

- Energy reduction

- Compressed air energy savings

Identify leaks in real time

A large manufacturing plant utilizes compressed air for clamping devices, stamping machines, tool powering and cleaning.

- Leaks caused tools to work inefficiently.

- Products were affected and resulted in loss of profits.

- A system was needed to lower annual energy spending without significant capital investment.

Identify air leaks in real time, convert sensor values to useful data and calculate savings

ifm's moneo Real-Time Monitoring System reduces energy costs linked to compressed air or gas leaks, maximizes machine performance with the proper compressed air or gas supply, and frees up the maintenance team to do value-added work versus time-based maintenance checks.

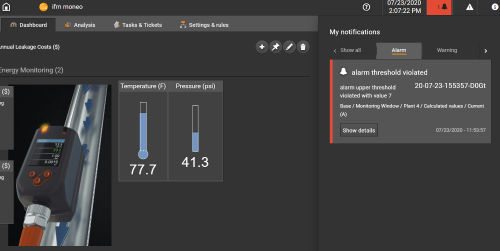

- moneo converts pressure, flow and air flow values to relevant information to add clarity to the process.

- moneo provides analysis and trending of air lines, records total consumption and identifies savings potential.

- moneo is an independent system with an IPC pre-loaded with easy-to-use software without the need for a PLC.

Perform simple math functions without a PLC. Shown here is calculation of annual energy cost.

Set alarm thresholds for email and SMS alerts