Automated dairy systems: A revolution in dairy farming

Imagine a dairy farm that's not just more efficient but also more profitable and humane. Automated dairy systems offer the exact solutions for the challenges every farmer faces, from improving milk quality to optimizing cow health.

Thanks to Artificial Intelligence and Internet of Things technology, automated dairy systems are creating a smarter, more efficient dairy industry for operations of all sizes. Say goodbye to rising labor costs and manual inefficiencies, and say hello to proactive management, real-time health monitoring, and data-driven decision-making.

- Reduced cost: Automation significantly reduced the need for manual labor, one of the largest expenditures for dairy farmers.

- Proactive management: Farmers can focus more on strategic tasks with automation for labor-intensive tasks.

- Improved milk quality: Control systems ensure standardized dairy processing, resulting in consistently high-quality milk, cheese, yogurt, and other dairy products.

- Optimized feeding: Automated milking and feeding systems tailor nutrition to each cow, positively impacting milk yield and overall cow health.

- Enhanced animal welfare: Milking systems can operate around-the-clock, allowing them to milk cows when the animals feel the urge, ultimately enhancing their well-being.

- Real-time health monitoring: Sensors and tracking devices monitor environmental conditions for optimum dairy processing and storage.

- Traceability for food safety: Automated systems can track from the specific cow and pasture, all the way to the packaged product.

- Data-driven insights: With automated systems, dairy farmers can make data-driven decisions, which is crucial for effective management.

Dairy automation uses

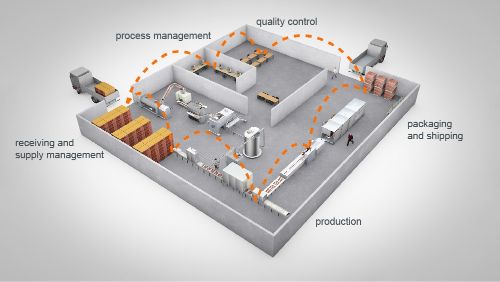

Robotic milking is just one small part of what an automated dairy system offers. Automation permeates every corner of the dairy industry, from farm operations to food production to packaging.

Milk processing

Automated pasteurization and homogenization processes eliminate harmful pathogens while preserving the milk's nutritional value. Temperature and pressure sensors ensure production meets all quality standards. Modern systems also enable real-time monitoring, reducing human intervention and minimizing errors.

Cheese-making

Initial milk composition, moisture level, pH, stirring rates, and levels of salt addition all influence the cheese-making process. Automation maintains consistent conditions during fermentation, curd cutting, and whey separation. This results in batch-to-batch uniformity and premium-quality cheeses that delight taste buds worldwide.

Yogurts and desserts

From blending ingredients to precise fermentation, automated systems ensure that each yogurt cup boasts the same creamy goodness. Automation also enables efficient mixing and processing of ingredients to achieve the desired texture, viscosity, and taste for a spectrum of sweet dairy delights.

Dairy packaging

Dairy packaging lines have embraced automation to enhance efficiency and hygiene. Robotic arms deftly fill containers, while labeling and sealing machines guarantee product integrity. This streamlines the packaging process and extends the shelf life of dairy products. Efficient packaging designs can help reduce production and transportation costs.

Is dairy technology worth it?

Dairy technology is worth the cost thanks to its spectacular ROI. Along with promoting cow health, automatic milking systems increase the number of milkings per cow per day while reducing the human labor necessary for it.

Automated dairy system cost

The average cost of a milking robot is between $150,000 to $200,000. Each robot can milk 50 to 70 cows while adding an average one extra milking per cow per day.

Automated dairy system ROI

Milking robots boost production while reducing costs. To calculate your ROI:

- Take your current average milk production.

- Multiply the current average by an estimated increase of milk production (15%).

- Multiply the new average milk production by the total cows milking per day by 30 days.

- Multiply the average monthly milk production by the price per lb.

- The increased monthly revenue is the monthly milk revenue + the labor savings.

For most farms, the increase in production and reduced labor costs quickly outweigh the investment cost of the milking unit.

The new dairy processing technologies

- Advanced sensors: Instruments like conductivity, pressure, and temperature sensors ensure product consistency.

- Cameras and code readers: Code readers can identify date codes and other important marks. This allows for identification and removal of affected products in the case of a quality issue or safety concern.

- Robotics: Robotics can perform tasks like feeding and cleaning along with automated milking systems.

- IoT Integration: The Internet of Things (IoT) allows devices and systems to communicate, share data, and make automated, real-time decisions.

- AI and Machine Learning: AI systems analyze vast datasets to optimize products and processes. These programs predict yields, detect diseases, and fine-tune overall farm operations.

How do automated dairy systems work?

Automated systems utilize a combination of sensors, data analytics, and real-time monitoring. They collect valuable data including milk yield, cow health, and milk quality.

When farmers receive this data in real time, they can make decisions that improve milk production and animal welfare. And they do so while reducing expenses, even as labor costs keep rising.

The future of dairy automation

In the rapidly evolving landscape of dairy automation, leveraging artificial intelligence and machine learning for predictive maintenance and quality control can reduce downtime and enhance product consistency.

Integration with the Internet of Things (IoT) can enable real-time monitoring of dairy operations, ensuring optimal conditions for both product and equipment. Moreover, sustainable practices and eco-friendly packaging solutions align with consumer preferences and environmental concerns, providing a distinct advantage.

Automated storage and retrieval systems

Automated storage and retrieval systems (AS/RS) are great for space optimization, reduced labor costs, inventory and picking accuracy, and scalability. In dairy systems, AS/RS is important for inventory management and product traceability giving the ability to handle variability, variety and high volume at higher speeds. AS/RS systems operate efficiently and consistently, reducing downtime and streamlining the movement of ingredients and finished products within a dairy facility.

Efficient inventory management

AS/RS efficiently manage and organize inventory, which is crucial in dairy production where precise control of ingredients and perishable raw materials is essential. It reduces the risk of stockouts, overstocking, and product waste.

Product traceability

AS/RS systems can be integrated with tracking and tracing technology, ensuring that dairy products are stored and retrieved in accordance with strict quality and safety standards. This enhances traceability throughout the production process.

Gain a competitive edge

To thrive in the future of dairy automation, companies must not only invest in technology but also prioritize agility, adaptability, and a commitment to meeting evolving consumer demands for quality, safety, and sustainability. Contact ifm to learn more about how our automated dairy solutions can give your farm the tools to thrive.