Wine automation: where technology meets tradition to enhance quality

In the heart of every vineyard lies a passion for crafting the perfect bottle of wine. Now, state-of-the-art process technology makes it easier for vintners to create perfect batch after perfect batch. And, they can do it without compromising the principles and traditions of their age-old craft.

Automation is helping wineries increase product quality despite labor challenges and climate change. It is helping them better monitor their production processes to reduce wasted resource consumption and protect the climate that is so vital to the longevity of the industry.

Enhance quality control

Continuous monitoring throughout the winemaking process ensures every bottle adheres to desired flavor profiles and quality standards.

Reduce costs

Automation reduces the need for manual labor in tasks like grape sorting, crushing, and bottling. This frees scarce labor resources to focus on more valuable work.

Increase sustainability

Using real-time data, precision monitoring of energy and water consumption lead to better resource management and conservation.

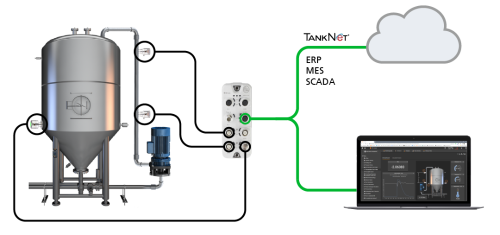

Automated brix monitoring

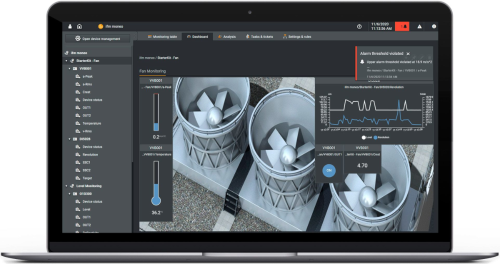

By installing sensors on a fermentation tank or pumpover line, wineries can monitor fermentation progress in real time. The brix curve populates automatically with this data using software on your laptop, so you can visualize fermentation occurring in each tank. This real-time monitoring provides actionable data to the winemaker, so they can ensure that fermentation is progressing along the desired brix curve and can take action if fermentation stalls. Learn how to improve wine quality with continuous brix monitoring.

Improve wine quality

Reduce common causes of failure with instrumentation that:

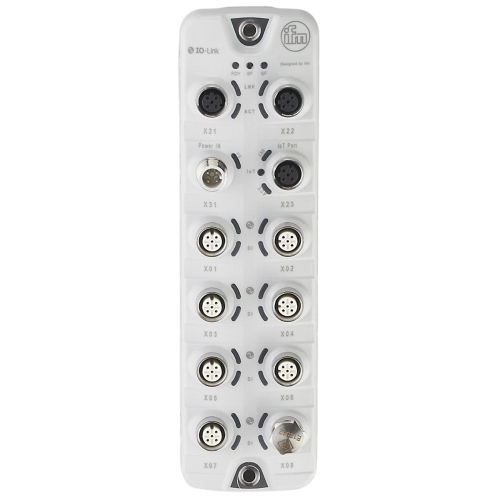

- Use IO-Link to eliminate analog conversion inaccuracies

- Eliminate moisture ingress

- Proactively alert you to drift

By implementing more robust process instruments that are less prone to common causes of failure, you can feel confident in the accuracy of your measurements. Improve precision control throughout the winemaking process to ensure consistency in every bottle.

Increase efficiency

With automated instrumentation for common winemaking equipment, wineries can increase efficiency while also improving quality. The benefits include:

- Reduce risk of error in manual processes

- Increase insight into winemaking

- Fills labor shortage gaps

This allows you to continue normal winery operations, despite scarce seasonal labor during the growing and harvesting season. Designed for use in sanitary environments of beverage production, ifm products help provide high accuracy and reliability for winemaking.

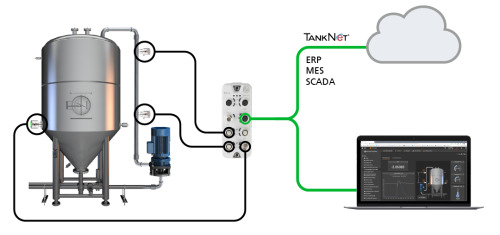

Precision harvesting

Devices like 3D cameras help mechanical harvesters with:

- Autonomous navigation

- Obstacle detection

Onboard algorithms process the 3D camera data to update line guidance in real-time to ensure a perfect harvest, thereby increasing efficiency and reducing labor requirements in modern vineyard management. ifm offers a full portfolio of solutions for vineyard equipment, including harvesters and combines.

Inventory optimization

Sensors equipped with IO-Link technology can send data to higher level software systems in the cloud, including ERP systems. This allows supply chain specialists access to important data that can help them predict future inventory needs.

Software platforms that receive machine data can trend production levels in real-time to avoid downtime during peak production hours. This allows wineries to scale production up or down more easily to meet market demands.

Optimize resource consumption

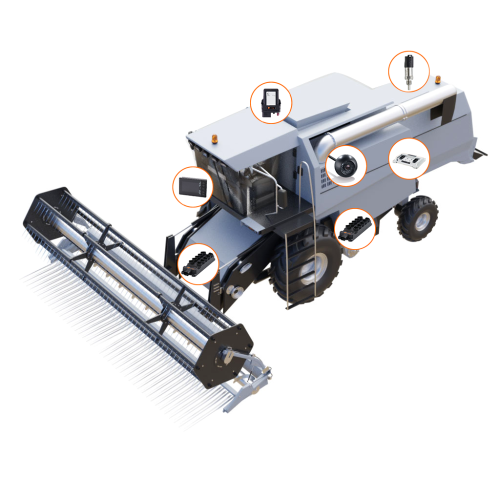

The wine industry is dependent on a stable climate and weather cycles that impact grape harvests. Measuring the impact of wine production on the environment is important for the longevity of the industry. Smart flow meters can be used to monitor and reduce:

- Water consumption

- Energy consumption

- Chemical consumption

Benchmarking current consumption levels can help wineries quantify their sustainability initiatives and save resources. Additionally, automating the collection of this data is important to comply with government regulations.

Automation of water catches

Implementing strategic instrumentation between tanks can help wineries save water when using it to push wine through the lines. This case study explores how simple monitoring solutions can eliminate the manual processes involved, saving both labor and water costs.

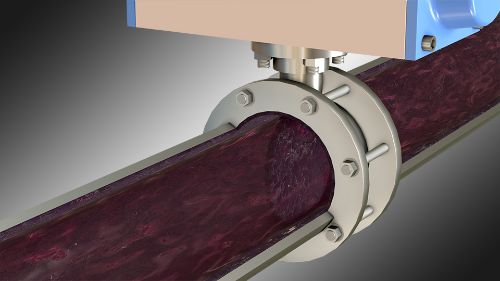

Smart valve monitoring

Enhanced valve control when moving water or wine throughout a winery helps to ensure that it is not diluted or contaminated. Smart valve solutions increase visibility to valve seal degradation and any build-up due to grape skins or other organic material. This provides real-time information that allows a winemaker to catch an issue before wine quality is impacted.

IO-Link provides a flexible communication protocol for connecting smart sensors. As part of an open consortium, it is technology agnostic. The purely digital signal provides more accurate resolution compared to traditional analog technology.

Pressure sensors or level sensors provide high degrees of accuracy and reliability for optimal machine design. Designed to withstand caustic cleaning solutions and washdown, they are rigorously tested to prevent moisture ingress and other common causes of sensor failures.

Conductivity sensors provide real-time measurements that allow you to monitor skid health in a variety of applications. The price performance ratio allows you to implement multiple data points on a machine for increased insight into processes.

Temperature sensors provide real-time monitoring of the media. Designed to withstand caustic cleaning solutions and washdown, they are rigorously tested to prevent moisture ingress and other common causes of sensor failures.

Flow sensors are critical for monitoring flow rate, totalizing functionality, and media temperature in real time. Receive all of these process values from one sensor over IO-Link for real-time monitoring of your batch during production.

moneo|software seamlessly visualize machine health, trend and store process data, and implement alarms. Built for easy integration and setup, get started in hours, not weeks.

Smart valve position sensors provide precision control of valves and real-time monitoring of valve position. These smart sensors help improve wine quality and reduce risk of contamination by proactively alerting to build-up in pipes that might block valves from fully closing.

Preparing for the future

Is change the biggest challenge for the wine industry?

While the benefits of automation are numerous, the transition is not always easy for winemakers. Perhaps more here than with other industries, it's especially challenging to strike a balance between tradition and technology. Many vintners may worry that automation interferes with the craft of winemaking. However, the key is integrating technology without compromising the artistry and tradition that make every bottle unique.

The purpose of wine automation is to make it easier and more cost-efficient to fully realize each vintner's unique vision. It provides the flexibility to experiment with custom blends on a larger scale. Ultimately, increased efficiency, improved yields, and enhanced quality help the industry cultivate tradition without sacrificing the craft of winemaking.

Each bottle of wine is a reflection of art and science. In an era where the lines between tradition and technology blur, wineries that adapt and innovate will thrive. That's why more winemakers are embracing automation and the vast array of related technologies.