- Autonomous mobile robots

- Business challenges

- Buy decision

When is “Buy” better than “Make” for robotics systems?

Is time-to-market becoming a critical factor in the success of your autonomous robotics line? Are you concerned about having to sacrifice functionality in order to meet deadlines and keep your product?

If so, it’s time to consider whether you can buy hardware or software instead of developing another proprietary system.

There are advantages to creating all your own systems. But, in many cases, and especially when time is becoming more of a challenge, purchasing one is the better bet.

In this article, we’ll outline the four benefits of purchasing your obstacle detection or pallet detection systems. We’ll also explore what the options look like, and the steps you’ll need to take for a successful integration.

Enhanced value for the end-user

A cutting-edge, off-the-shelf ODS or PDS can be the differentiator that sends more sales our way.

Developers can’t do much more to cut the cost of a mobile robot. Instead, a robot with better throughput capabilities creates tens or hundreds of thousands of dollars in savings for your client.

An obstacle detection that reduces unplanned stops and a pallett detection system that’s more accurate than its competitors create that added efficiency.

Preparing to buy an obstacle detection system

-

Time-to-market needs evaluation: If rapid deployment is crucial, purchasing an ODS can significantly accelerate this process.

-

Resource allocation analysis: Determine how much time and manpower are currently devoted to tasks that could be outsourced through ODS purchasing.

-

Risk assessment: Understand the potential challenges of maintaining an in-house ODS versus outsourcing. This should include considerations of technological obsolescence, compatibility issues, and resource allocation.

-

Cost-benefit analysis: This analysis should include direct costs, potential savings in manpower and time, and the indirect benefits of staying on the cutting edge of technology.

Evaluating vendors and options

-

Find the right vendors: Research and choose vendors who have a track record of overcoming common technical challenges such as floor segmentation and false positive mitigation.

-

Vendor reliability evaluation: Look for vendors who are known for ongoing development and customer support.

-

Integration strategy: Ensure compatibility and plan for any necessary adaptations in your robotics platforms.

-

Maintenance and update planning: Coordinate with your ODS vendor to understand their update and maintenance schedule. Plan how these updates will be implemented in your systems with minimal disruption.

Implementing the obstacle detection system

-

Training and knowledge transfer: Leverage the system’s advanced features and capabilities by investing in training for your engineering team.

-

Feedback loop establishment: Create a feedback mechanism with your ODS vendor for continuous improvement and customization based on your specific needs and experiences.

-

Leverage vendor expertise: Utilize their expertise to streamline the integration process and troubleshoot any issues that arise during implementation.

Vendor collaboration: Collaborative partnerships can involve joint development efforts, customizations, or extended support to ensure the ODS aligns perfectly with your robotic systems.

Does the option to buy really exist?

Until recently, robotics engineers didn't really have a choice but to develop their own obstacle detection and pallett detection systems. While 3D cameras and basic recognition systems were available, none truly addressed the specific needs of autonomous mobile robots.

At best, developers could find a few components off-the-shelf. Then, they’d have to integrate them all without using up too much processing power and still solve problems these solutions didn’t address.

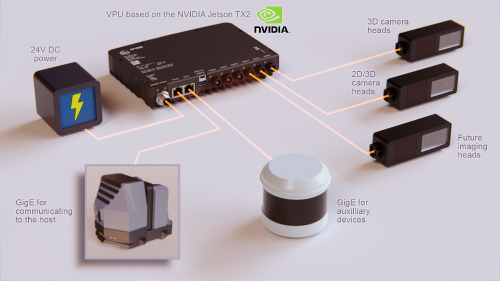

That’s changing now with ifm’s multi-modal camera systems and related software.

We leveraged our decades of experience in automation and sensing to develop solutions tailor-made to address the problem statements in modern robotics.

Our solutions are all-in-one packages that use open software and the most common programming languages to make integration fast and easy. And, our edge compute design drastically reduces the amount of processing power it requires from your core processor.

<< Why AMRs haven't reached mass adoption | Creating an obstacle detection system >>

Gain a competitive edge

Ready to learn more about accelerating your robot development?

Fill out our form or contact Tim McCarver directly at tim.mccarver@ifm.com.