- Autonomous mobile robots

- Pallet detection algorithm

Pallet Pick & Drop System: Now 10x faster

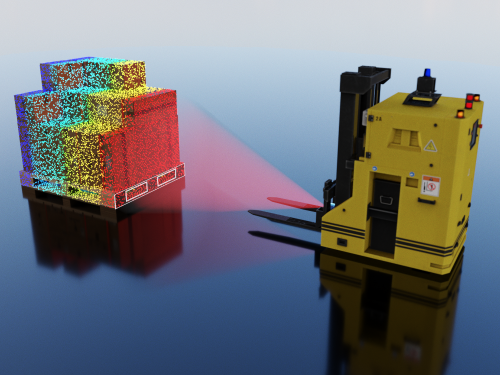

The impact of labor shortages and increased consumer demand has turned logistics automation into a necessity of warehouse operations today. Automated fork trucks and other automated mobile robots can increase operational flow with fewer human workers – but only if they are reliable and accurate. With the Pick & Drop System (PDS) software from ifm, automated vehicles detect pallet pockets quickly, pick and drop more accurately, and avoid collisions.

Our algorithm achieves high accuracy, because it is continuously experiencing anomalies in real warehouse environments with over 1,700 vehicle installs worldwide and more than 10 million successful picks. Thanks to rigorous real-world testing and relentless innovation, ifm's PDS algorithm works in countless unique scenarios in virtually any environment. It can detect and accurately pick the 6-DoF pose of all standard 2-pocket pallets.

Increase efficiency of robot fleets

Increase ROI of each automated forklift by improving overall throughput with faster pallet picks and drops.

Bring certainty to unpredictable environments

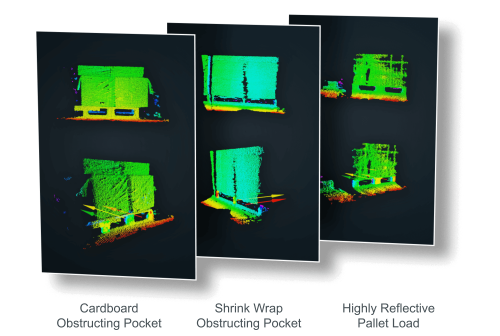

Software that provides high accuracy and reliability to overcome the biggest challenge in pallet detection: variability of pallet materials, colors, and conditions.

Reduce development time

Implementing a software solution that is optimized for easy integration frees development capacity to focus on your core IP.

Pick & Drop System hardware upgrades

The ifm Pick & Drop System continues to advance and adapt. The software solution is now available to run on the O3R, our newest robotic perception platform.

The main advantage of this switch in hardware is that each pallet pick drops from 2+ seconds to 0.2 seconds. The significant reduction in pick time is due to increased computational power achieved by moving the algorithm from onboard the camera to a separate processing platform. Using the NVIDIA Jetson platform®, the separate VPU optimizes speed and efficiency of pallet picks, while also creating a more flexible hardware architecture.

The Pick & Drop System from ifm increases the efficiency of autonomous and semi-autonomous vehicles. It increases the speed of detecting the pallet pose without sacrificing the quality of the detection. It ensures your automated vehicles reliably select and place pallets, even in the most demanding conditions.

Simplifying a complex task

Automated fork trucks face a many challenges, from navigating busy plant floors to the precise task of engaging with their environments. But, the ideal condition of a perfect pallet is a rarity in the real world of manufacturing and logistics.

Pallets endure wear and tear, making them harder for most mobile robots to recognize and handle over time. Even an excessive amount of dirt or shrink wrap can prevent an automated forklift from recognizing its target.

Once a pallet is picked up by an autonomous or semi-autonomous vehicle, verifying the space before dropping a pallet is also a significant and complex task. The PDS solution from ifm can localize racking systems, verify that the intended space is free of obstacles, and complete a volume sweep to ensure the space is large enough to fit the pallet load. By reducing complexity on both sides of moving a pallet, the PDS solution significantly reduces time per mission and increases throughput.

ROI for OEM manufacturers and end users

The next challenge is efficiency: How many trips can your automated fork truck make in a day? How many fewer trips will it complete when it has to stop because it misidentifies a target? Increased throughput is what makes the capital expense of a mobile robot worth it to a warehouse facility. Unexpected stops and bad picks reduce that value. OEE (Overall Equipment Effectiveness) is the gold standard for measuring manufacturing productivity. Simply put – it identifies the percentage of manufacturing time that is truly productive.

Instead of focusing solely on hardware cost reductions, an OEM can add value to their robot fleet by increasing vehicle efficiency. Then, the end user can do more with fewer units, justifying the capital expense.

The PDS algorithm increases efficiency by reducing the length of each pallet pick. The increase computational power of moving our algorithm to the O3R platform has reduced pick time from 2+ seconds to 0.2 seconds, again drastically increasing throughput of each vehicle.

The future of pallet detection

Mobile robots have yet to “cross the chasm” into mass adoption. But, robust features like pallet detection and obstacle detection quickly increase the efficacy and value of AMRs.

As pallet detection systems improve, robots will be able to work faster and with more accuracy. This will increase their value, making them more affordable to both large- and mid-size companies. While each copmany may require less robots in a fleet to complete their work, this significantly increases the number of potential customers and helps drive increased demand overall.

The benefits of real-world experience

Thanks to data and development from millions of picks, the PDS software from ifm not only understands the geometric complexities of pallets, but turns this knowledge into actionable data. This accumulation of data points over time has refined the intelligence of the system, making it unique in the value it brings to semi-autonomous and autonomous vehicles.

Our algorithms account for countless nuances, unexpected problems, outlier geometries, and other variables. We provide 1-centimeter precision in positioning and orientation, ensuring that each interaction with a pallet is seamless and exact.

Innovation never stops. Our algorithm is always adapting to new challenges, such as varying pallet sizes and unique requirements. You benefit from the accumulation of this increased dataset with continual updates.

The above pallets are examples of those detected by PDS, but it is not limited to the pallet types above.

Increase confidence in every scenario

With millions of successful picks and drops, our PDS solution has seen it all. We know that every deployment is unique, even across locations within the same company. Sometimes, endusers have anomalies at their site that even they did not anticipate to communicate proactively before deployment.

ifm is a dedicated partner to helping you gain the most efficiency from integrating our PDS solution. Over the years, our customers have come across anomalies at their deployment sites. The PDS vision assistant software includes features that reduce friction, such as:

- Recording frames during a pick or drop

- Adding custom pallets

When encountering a unique scenario for the first time, our customers can record 4-5 frames of the new pick and drop, and then our team can assist in determining what parameters to adjust to achieve success. By adding custom pallets through the vision assistant tool, you can ensure that the PDS solution learns and understands your unique pallets for even better performance.

Pallet detection platform components

OVP vision processing unit specifications

- Ethernet ports: 2x 1 GigE

- Camera ports: 6x proprietary 2D/3D camera ports

- Power: 24 VDC and CAN

- USB ports: USB 3.0 + USB 2.0

O3R 2D / 3D head

Accessories

Gain a competitive edge

Are you ready to take your mobile robot development to the next level? Fill out the form or contact Tim McCarver directly at tim.mccarver@ifm.com.