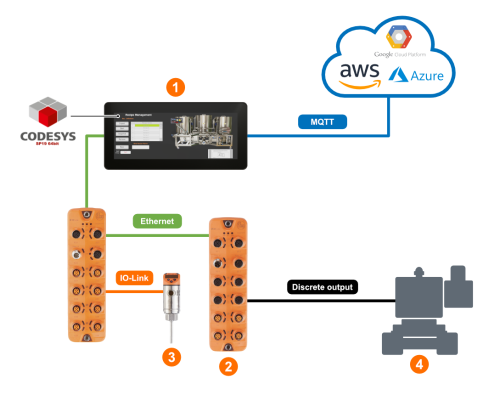

Upgrade your machine for Industry 4.0

| Reduce the total cost of a machine: | Improve the user experience for the machine operator: | Gain remote access to your machines: | ||

|---|---|---|---|---|

|

|

|

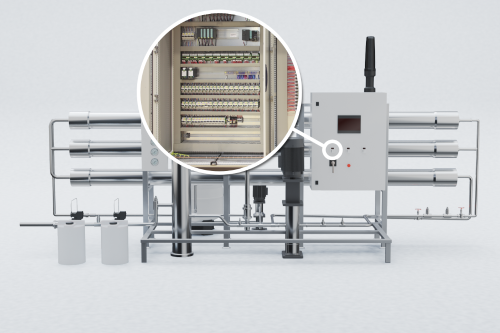

Traditional control panel with HMI + PLC + input cards

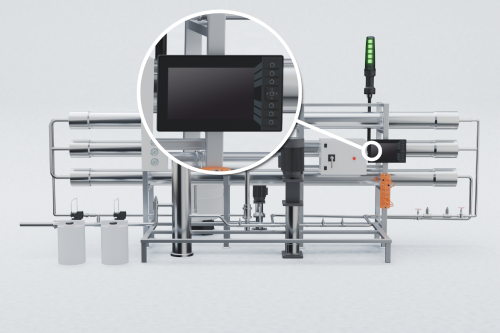

Field mountable HMI controller with integrated PLC functions and connection to field I/O

Development:

- Unnecessary software management: A two-piece system (PLC + HMI) requires separate software for each component.

- Software constraints: Restricted to one programming language (e.g., ladder logic)

- Proprietary software subscriptions: Expertise in proprietary software is also necessary.

- Analog-to-digital conversion errors: Potential data losses occur when the signal converts from analog to digital to integrate with software.

Development:

- Simple software management: An all-in-one (PLC + HMI) controller uses one free programming software

- Software flexibility: Supports multiple programming languages (e.g., ladder logic, structured text, sequential function chart (SFC), function block diagram (FBD), and control flow chart (CFC)).

- Additional software benefits: Includes built-in IIoT functionality and features like recipe management, trending, and data logging.

- Enhance process data quality: Digital communication eliminates analog-to-digital conversion errors and provides diagnostics.

Production:

- Labor and assembly challenges: Wiring harnesses, terminating wires, and IO cards can increase labor. Integrating third-party control panels can lead to longer assembly times.

- Unnecessary hardware management: A two-piece system (PLC + HMI) requires larger cabinets and excessive terminal wiring.

Production:

- Streamline labor and assembly: An all-in-one (PLC + HMI) IP67 rated controller that is field mountable eliminates the need for separate control cabinets and terminal wiring.

- Improve scalability: Reduced BOMs and M12 connection technology lead to faster build times.

Service:

- Troubleshooting challenges: Wiring harnesses, terminating wires, and IO cards increase troubleshooting times.

- Complex interface: Complicated display navigation requires training.

Service:

- Expedite installation and troubleshooting: M12 connection technology facilitates ease of assembly and allows for field IO connections.

- Improve operator experience: Create an intuitive experience with fully customizable high-resolution and touch screen displays. Eliminate human error with real-time feedback and alerts.

Financial:

- Increased lead times: Integrating third-party control panels can lead to higher costs and longer lead times.

- Reoccurring costs: Proprietary software subrscriptions and support.

- Hardware costs: Increased BOM leads to higher costs in components, labor, space requirements, maintenance, and support.

Financial:

- Reduce lead times: Reduced BOM and M12 technology improve efficiency to meet customer demands.

- Cost savings: No additional costs for software benefits.

- Labor savings: Eliminating terminal wiring leads to savings in material costs, labor-intenseive processes, and maintenance and troubleshooting costs.

Typical PLC controller |

ifm HMI controller |

|

| Controller / PLC | ||

| Processor | Proprietary | ARM Quadcore, 64 bits, 1.2 GHz GPU |

| Memory | Typically 2 MB | 8 GB |

| Communication protocol | EtherNet/IP | EtherNet/IP, TCP/IP, Modbus TCP |

| Built-in ports | 2 Ethernet, 1 USB | 2 Ethernet, 2 USB |

| Support dual IP | no (additional cost) | yes |

| I/O | ||

| Mounting | Cabinet mount I/O | Field mount I/O |

| Type of I/O | Analog or binary I/O | IO-Link technology |

| Amount of data | 1 bit on/off or 16 bits analog | 32 bytes of inputs and outputs per port |

| Sensor diagnostics | no | yes |

| Remote parameters adjustment | no | yes |

| Automatic device replacement | no | yes - simple plug-and-play |

| Digital communication | no | yes - 100% pure digital signal |

| Maximum I/O | 8 input/output cards or 256 digital inputs/outputs | 30 IO-Link masters or 240 IO-Link sensors/devices |

| Installation | Traditional wiring harness, labor intensive, complex troubleshooting | M12 plug-and-play, not wiring harness, time saving |

| HMI display | ||

| Size and resolution | Not included, purchase additional HMI hardware separately | 12" x 5", 1280 x 480 resolution |

| Display type | N/A | Touch screen |

| Software | ||

| Programming software | Additional cost, license or subscription model | CODESYS (IEC 61131-3) |

| Recipe/batch management | Additional cost, license or subscription model | Supported, included with hardware |

| HMI software | Not included, purchase hardware and software separately | Supported, included with hardware |

| Trending | Not included, purchase software separately | yes |

| Alarming | Not included, purchase software separately | yes |

| Mechanical properties | ||

| Protection rating | Control cabinet required | IP 67 |

| Vibration | 5 g @ 10...500 Hz | 10 g @ 10...500 Hz |

| Shock, operating | 20 g | 30 g |

| Temperature | 0...60 ºC | -35...65 ºC |