Track and trace (TTQ) solutions for manufacturing

Track and Trace (TTQ) solutions by ifm offer innovative ways to improve manufacturing efficiency and address the Six Big Losses. This article provides an overview of:

- Impact of TTQ solutions on production efficiencies and quality improvement.

- Advanced tracking technologies for raw materials and returnable assets management.

- Smart tooling and error-proofing techniques in manufacturing processes.

- Applications in access control, work-in-progress management, packaging, and storage.

Smart tracking solutions address the Six Big Losses

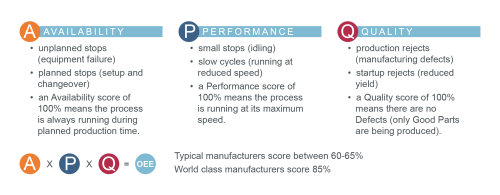

ifm TTQ (Track, Trace, and Quality) solutions target the Six Big Losses on efficiency. Whether you are looking to improve availability scores with returnable asset tracking, or to improve quality with automatic machine set up and RFID enabled smart tooling, it is important to understand how specific solutions impact production efficiencies.

What if everything you produced was of the highest quality?

What if every shipment that left your facility was 100% accurate, every time?

What if you always knew the location of every tool or raw material?

What if you could quickly raise operating efficiency by implementing a tracking solution?

ifm tracking solutions address every aspect of OEE (overall equipment effectiveness). With all resources in one place, it’s never been easier to choose your next continuous process improvement project to boost efficiency. Identify a tracking solution to benefit your facility and get started below.

Tracking technologies applied to raw material storage and retrieval ensure that production never stops, enabling:

- Automatic and reliable raw material location tracking

- Real-time accurate inventories and minimization of lot sizes

- Autonomous tracking for fixed storage bays and unstructured environments

Tracking container assets within a facility increases availability for production while protecting a manufacturer from unexpected losses and fines by enabling:

- Real time location tracking of assets within the facility

- Validation of receipt and shipment of high value assets for production

- Communication to many databases and software suites at once

By applying serialized identifiers, tracking technology enables smart tooling capabilities within production processes and machinery, enabling:

- Confirmation of the correct tool for the job at hand

- Real time location tracking and maintenance data storage

- Automatic configuration of machine parameters for the installed tool

Identification technology enables manufacturing processes to proactively prevent errors from occurring. Ensure every product is made to specification with zero mistakes by enabling:

- Defect identification within production/assembly at the point of error

- Real time tracking of a “batch of one” throughout production

- Effective quarantine, accurate rework, and scrap rate tracking

Tracking technologies ensures the right people are at the right machine at the right time so critical assets are managed properly, enabling:

- Varying levels of access to machine adjustments and process changes

- Optimization of your workforce; the right person on the right machine

- Enhanced security, and protection of machine assets in complex processes

Tracking work-in-progress (WIP) gives real-time insight as to what is in production, giving the ability to create a digital twin of the production floor, enabling:

- Effective, lean, and intelligent production

- Real time optimization of production scheduling

- Location tracking of WIP subassemblies and needed material inventories

Ensuring the correct packaging is used for your product is a critical control point for any robust quality control program. Adding unique identifiers on bulk packages or shipments enables:

- Effective mixed-lot prevention measures in production/packaging

- Reduction in lot sizes, limiting potential impact of a product recall/rework

- Location tracking, shipment verification, and product sequencing of finished goods

UHF RFID technology enables a low cost, highly effective inventory tracking and localization capabilities by enabling:

- Real time tracking and inventory of finished goods into/out of storage bays

- Localization of finished goods in unstructured environments with mobile automation

- Location and destination prompt to personnel to reduce sourcing and shipment time

Serialization of shipping units unlocks the capability of ensuring that every order is complete and sequenced by enabling:

- Sequencing verification for JIT (Just in Time) Manufacturing

- Automatic shipment manifest and verification with timestamps

- Reliable recording of all activated shipping units moved through portal control