ISV Umwelt – Clean separation achieved

The municipal sewage treatment plant in Diepholz is one of ISV Umwelt's customers.

Compact plant for dewatering biomass

Sewage sludge is prepared for thermal processing by means of a centrifuge. A comprehensive set of sensors enables precise monitoring of the plant, both on site and remotely. Moreover, thanks to IO-Link, the installation, commissioning and service processes are particularly efficient.

Almost 2 million tonnes of sewage sludge annually are produced in around 10,000 sewage treatment plants in Germany. While previously most sewage sludge has been used as fertiliser in agriculture, more and more sludge is now being recycled thermally for environmental reasons. Legal requirements in Germany require that all sewage sludge must be used for phosphorus recovery in mono-incineration plant from 2029 at the latest.

However, before sewage sludge can be used as fuel in the first place, its solid contents must be separated from the high water content - which makes up over 97 per cent of the mass.

This is where the company ISV Umwelt, from Langelsheim in Lower Saxony comes into play. Founder and Managing Director Sven Penkwitt explains: "We build mobile biomass dewatering plants and rent them to our customers either on a temporary or permanent basis.

One of these customers is the municipal sewage treatment plant in Diepholz where ISV-Umwelt sets up one of its plants for a one week period about four times a year. "In this period, around 72 tonnes of dry matter, which can then be used for thermal recycling, are separated from around 2400 cubic metres of digested sludge that accumulates in large basins over a period of three months."

The sewage sludge (left) is separated into water (centre) and dry substrate (on the tray on the right).

Separation with centrifuge

The separation plant is a self-sufficient system and housed in a 12-metre-long mobile container. The centrepiece is a decanter centrifuge. Its drum rotates at 3,200 revolutions per minute, generating centrifugal forces equivalent to 3,000 times the gravitational acceleration. When the sewage is fed from the collection basins with pump and hose, the heavy solids are pressed outwards. From there, they are led to the outside by means of screw conveyors, while the lighter water remains in the centre of the drum and flows off. A conveyor belt then takes them to a collection container for transport to the CHP plant. A flocculant is added to optimise the separation. The type and dosage of this is adjusted to the respective composition of the sewage sludge.

To achieve an optimum dewatering result, it must be possible to adapt the process at various points, and this is where ifm comes in: As an automation specialist, ifm offers a wide portfolio of sensors and automation solutions that can be used to precisely adjust and transparently visualise analyse the process operations down to the last detail.

Monitoring the centrifuge

The two main bearings of the centrifuge are subject to extreme forces when the heavy drum spins the sometimes inhomogeneous sewage sludge at enormous speed. Therefore two VVB vibration sensors have been screwed into each bearing. They permanently monitor the vibration behaviour.

A vibration pattern that deviates from the norm allows to quickly detect whether the mass cannot be processed, i.e. separated, correctly because e.g. the consistency or viscosity is not right or coarse lumps get into the centrifuge. Then the service staff can intervene and, for example, reduce the speed of the centrifuge to prevent damage.

Wear on the drum bearings is also detected at an early stage via an increasing vibration amplitude and reported as a maintenance signal. What is more, the vibration sensor has an integrated temperature sensor. Increasing temperature values indicate increased friction due to wear.

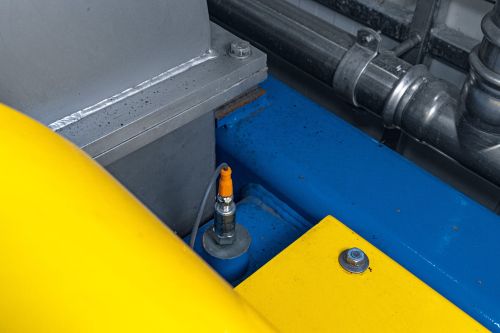

Picture 1: This decanter centrifuge, which separates water and dry matter at 3,000 times the gravitational acceleration, is the centrepiece of the plant. Picture 2: A vibration sensor ensures that no critical vibrations occur.

Almost 300 t of dry substrate are produced in Diepholz annually and thermally utilised.

Hydraulic power unit

A high-torque, hydraulically driven screw conveyor which compacts the solids and discharges them to the outside is located in the centre axis of the centrifuge. The pressure is generated by an electrically driven hydraulic unit. A PV8 pressure switch with a measuring range of 0 to 250 bar measures the hydraulic pressure to control the electric pump motor via a frequency converter. The pressure is therefore used to control the screw drive and ultimately the solids discharge of the plant.

There is also an LI5 series level sensor on the aggregate. It detects the oil level and also the oil temperature, and it gives a warning when permissible values are exceeded or fallen short of.

Monitoring of the hydraulic aggregate with regard to pressure, oil level and temperature.

The electrically driven hydraulic unit for the screw conveyor in the centrifuge.

Feed flow monitoring

The precisely metered inflow of sewage sludge into the centrifuge is crucial for an efficient separation process. For this purpose, a magnetic-inductive flow sensor is installed in the inflow. This sensor reliably detects the flow of a wide variety of liquid and viscous media, in this case the amount of biomass or sewage sludge that is added and that ranges from typically 15 to a maximum of 56 cubic metres per hour. This measured value is combined with both the feed pump and the centrifuge control in the plant controller. The sensor operates on the magnetic-inductive measuring principle. It offers the following advantage: the measuring section is free of any measuring element or other component that solid components of the sewage sludge could adhere to, blocking the pipe.

In addition, the sensor also measures the temperature of the conveyed sewage sludge. The viscosity of this sludge is higher in the cold seasons - a decisive factor that must be taken into account when feeding the centrifuge.

It's all about the mix

To achieve optimum phase separation (this is the term used by specialists for the separation of liquid and solids), a flocculant is added to the sewage sludge. The flocculant is individually adapted to the type of sewage sludge, i.e. the recipe varies depending on the sewage treatment plant. The flocculant consists of water and a polymer concentrate. Both are individually prepared ensuring an exact mixing ratio. A vortex flow sensor is used for this purpose. It precisely measures the water supplied to the preparation tank and thus regulates the recipe of the flocculant.

The preparation tank itself is monitored with the LR7000 level sensor, which has a probe with a guided microwave for level measurement. This measuring principle offers the advantage of not being affected by the foaming of the flocculant. In addition, the probe can be easily shortened and thus adapted to the height of the tank.

The readily prepared flocculant is fed into the centrifuge together with the sewage sludge. A SM8020 flow meter operating on the magnetic-inductive measuring principle precisely monitors the quantity supplied. Unlike the vortex sensor, this flow meter can not only detect water but any liquid media accurately, including the highly viscous polymeric flocculant.

Picture 1: The LR7000 level sensor uses a microwave to detect the level in the flocculant preparation tank. Picture 2: Various flow sensors help with the dosing of the flocculant.

Measurement at the storage tank

The storage tank with the polymer concentrate is monitored via the KQ1000 level sensor. This sensor is mounted on the outside of the tank and detects the fill level through the tank wall. Three switching signals with different priorities remind you to refill the tank. Sven Penkwitt has found a particularly pragmatic solution here: "Depending on the delivery time and the required quantity of the product, the sensor’s installation position on the supply tank may be higher or lower, which gives us flexibility in the lead time of the order."

The capacitive sensor detects the level of the polymer concentrate through the container wall and signals when supplies need to be ordered.

Central measured value: A magnetic-inductive flow sensor monitors the amount of sewage sludge entering the centrifuge.

Simple and easy with IO-Link

All sensors in this plant use the IO-Link communication protocol. Sven Penkwitt explains the advantages for his company: "IO-Link reduces the wiring effort and allows a much leaner commissioning. Structured wiring essentially consists of screwing connectors to sensors and modules. Sources of error, such as incorrectly connected cables, are eliminated. Our first plants were wired conventionally and we needed about 2 ½ days for this. Today, with IO-Link, it's done in 2 hours."

According to Penkwitt, one relevant advantage of IO-Link is in service: "I no longer need an electrician to replace a defective sensor; with the simple M12 connection, basically anyone can replace the sensor." Once the new sensor is inserted, it automatically receives its parameters from the IO-Link master: limit values or counter readings are thus simply transferred from the old to the new sensor. "So you can say that IO-Link minimises the downtime of the equipment on site at the customer."

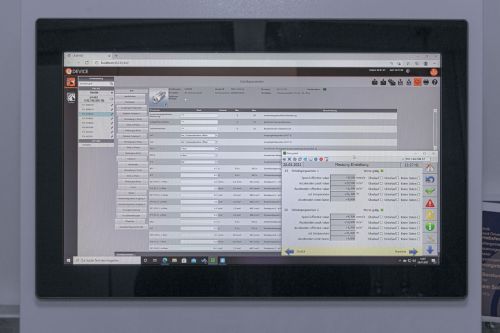

While conventional sensors only have switching or analogue outputs, IO-Link sensors also offer communication right into the sensor. For example, the complete parameterisation of the sensor can be carried out remotely - either manually by the operator via software or automatically by the controller, for example when a recipe is changed. This makes it easy to optimise the process remotely, right down to the sensor level.

In addition, IO-Link sensors offer additional diagnostic functions beyond the actual measured value, e.g. operating hours counter, min. and max. value memory or values on the quality of the measured signal.

"All control and monitoring activities on our plants can take place remotely. This is where IO-Link comes in very handy, as it gives us maximum transparency right into the sensor. This enables us to adapt the process optimally and quickly locate the source of the error when faults occur", says Sven Penkwitt.

Picture 1: All of the plant can be controlled and viewed remotely. Last but not least, IO-Link ensures maximum transparency. Picture 2: Thanks to IO-Link, the user can read measured values, change parameters and view min/max values and diagnostic data for each sensor via a dashboard.

Conclusion

The broad product portfolio makes it possible: with sensor technology from ifm and all the advantages of IO-Link, even a complex plant with many variables that have to be taken into account for maximum efficiency can be completely automated. However, it is not only the "hardware” that makes a difference, service, too, counts. This is how Sven Penkwitt sums it up: "The people at ifm understand what is at stake. They understand and support you, whether by phone and on site. The availability is also excellent: I call by 3pm and have my sensor the next day. This is of major importance for us in maintenance and service, because ultimately I am responsible towards my customers. I know of hardly any supplier in the electrotechnical sector that comes even close to this performance. That's why we rely on ifm wherever possible. Because we get everything we need from them: competence, reliability and speed."

Simple screw connections instead of cumbersome wiring: All sensors are connected to the IO-Link master, which transmits the signals via Profinet to the plant controller.