Autonomous mobile robots: Meeting today’s industry demands

Autonomous mobile robots address escalating labor costs, dwindling workforces, and increasing consumer demand. They also help meet operational efficiency, speed, precision, and safety KPI's.

But while autonomous mobile robots, or AMRs, are approaching mass adoption, they haven’t crossed the chasm yet. Friction exists for end-users due to challenges concerning: intergration, deployment, and capital expenditure (CapEx).

ifm has the technology and expertise to help your robots reach more end-users and increase their value. Our rugged, robust solutions are easy to integrate no matter where you are in the development process.

The demand for autonomous mobile robots is on the rise

Labor shortage is a major catalyst for mobile robots’ widespread adoption for material handling and logistics. Leveraging automation and robotics addresses employee recruitment and retention challenges, and allows skilled human workers to focus on more intricate tasks.

However, robot technology has reached an economic stumbling block. Concentrating on component cost reduction only creates a short-term win with a limited effect. So, the focus shifts to creating more efficient robots so a facility can do more with fewer units.

With better obstacle detection, robots complete more missions faster. And, they require less downtime or human intervention.

An answer to labor shortages

Automated mobile robots perform repetitive tasks that previously required a human worker. But the goal of automation isn't to render the human workforce obsolete. Rather, it’s to amplify its effectiveness.

For instance, many warehouses use AMRs instead of employees to transport items across the facility. The shipper now focuses on quality control — verifying and confirming the right product for the order — while the robot handles delivery.

The result is a surge in productivity, even with less people. With a fleet of robots assisting the workforce, the warehouse processes multiple orders simultaneously.

This strategic shift doesn't just fill the gaps in labor. It propels the existing workforce into a more dynamic, efficient future.

Total U.S. employment

Why do less than 20% of facilities utilize mobile robots?

Labor shortages pose potential consequences:

-

Heightened workplace safety risks

-

Equipment damage

-

Inconsistent product quality

-

Order fulfillment delays

Mobile robots can address these challenges. But the costs are too expensive for broad market acceptance.

Entry points for mobile robots require a significant investment from the user. That increases the time necessary to achieve a strong ROI.

Manufacturers must compromise on hardware selection. Instead, they focus most on safety to reduce BoM costs. This limits a robot's overall flexibility, which, in turn, reduces its capability.

Overcoming financial hurdles

The biggest obstacle to widespread adoption of AMRs has been the significant CapEx required.

The 'Robots as a Service' (RAAS) leasing model made robots more accessible to mid-sized enterprises. But, it's still not enough to help autonomous mobile robots cross the chasm to mass adoption.

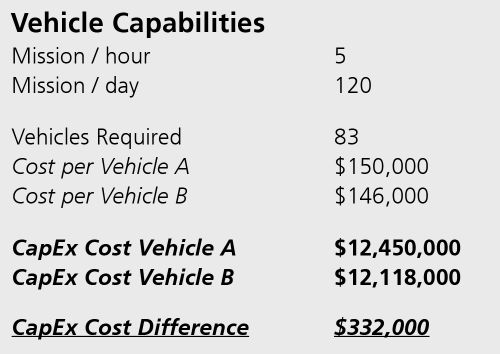

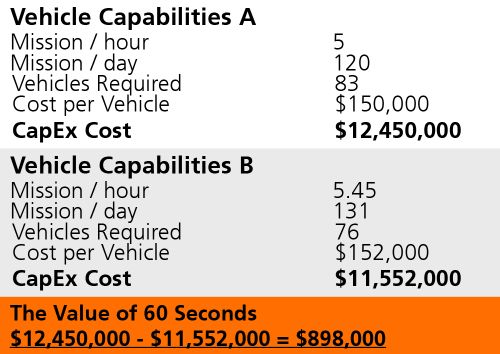

The next step is not cost-cutting, but performance enhancement: If an AMR fleet can complete its tasks faster, the entire system's throughput increases. That results in a direct reduction in the number of robots required.

This agility will allow large and mid-sized companies to achieve better throughput with fewer resources. This represents a revolutionary advantage that makes a tangible difference in operational budgets and growth trajectories.

Why obstacle detection is crucial for innovative AMR development

A robot’s ability to detect obstacles and navigate around them is now a core function that affects operational fluency. It's the key to increasing an AMR fleet's value.

Thanks to developments in 3D cameras over the last decade, we can get better results for less money. But, these products can’t come down much more in price. Nor can the cost of each robot.

AMR price tags range from $30,000 to $150,000. Small cost reductions or slightly shorter production times make virtually no impact on CapEx considerations.

The cost of the robot is essentially out of the value proposition. Now, the important question is: How many missions can it complete in a day? Each robot becomes more valuable as it increases the amount of work it can do.

Obstacle detection is the lynchpin to this equation. Imagine not losing time to unplanned stops that require human intervention.

When equipped with a smart and durable obstacle detection system, a robot adeptly avoids obstructions. This avoidance strategy leads to higher throughput, amplifying each robot's overall worth.

ROI for mobile robots: What your end user needs to see

As AMRs edge closer to mass adoption, the ROI calculation becomes less about a robot's cost, but the value each one adds.

Your end-user's fleet size drops significantly by improving an AMR's efficiency one minute at a time. A mission suddenly taking 11 minutes instead of 12 translates into real tangible savings.

That's not just cost reduction. It's capital expenditure transformation with a ripple effect on the entire order fulfillment operation.

When justifying the investment in mobile robots, your end user looks for tangible, impactful returns. When the cost of a robot can’t go any lower, the value of each unit must increase.

Gain a competitive edge

Are you ready to take your mobile robot development to the next level? Fill out the form or contact Tim McCarver directly at tim.mccarver@ifm.com.

Autonomous mobile robots (AMR) vs. Autonomous guided vehicle (AGV)

An autonomous mobile robot is a self-navigating, intelligent agent that understands and interacts with its environment without constant human oversight. This distinction marks a significant evolution from their predecessors: Autonomous guided vehicles (AGVs), which are confined to tracks or predefined paths.

Increased efficiency

Autonomous robots work non-stop, slashing downtime and boosting production. They adapt to workspace changes with quick programming, keeping operations smooth and efficient.

Enhanced productivity

These robots multitask, moving goods and managing inventory, which ramps up facility output. Their link to warehouse systems streamlines tasks and speeds up decisions, optimizing workflow.

Advanced quality control

Equipped with precise sensors, robots reduce human errors in handling, ensuring better product quality. Their reliability in repetitive tasks means consistent quality, improving customer trust.

Competitive advantage

Adopting these robots puts companies ahead with tech, drawing in customers valuing dependability and innovation. The data they gather helps firms stay competitive, guiding strategic decisions.

Added flexibility

Robots can be reprogrammed quickly and adjust to production shifts with ease. This makes them perfect for businesses with changing demands or those growing.

Improved worker safety

Robots handle the dangerous work, like heavy lifting, reducing accidents. They take on the mundane, too, letting employees focus on safer, more complex tasks, which boosts morale and safety.

Gain a competitive edge

Are you ready to take your mobile robot development to the next level? Fill out the form or contact Tim McCarver directly at tim.mccarver@ifm.com.