Automotive automation: Real-time improvements in manufacturing

The automotive industry is navigating the transition into a new era as manufacturers strive to meet evolving consumer demands and societal changes. High quality vehicles that are safe, reliable, and innovative are now the benchmark. Manufacturers need high-volume production lines as flexible as their evolving vehicles to offer mass customization, in order to meet increasing expectations.

As vehicles move from internal combustion engines to a hybrid and electric future, producers need to stay nimble, in order to keep costs controlled and pivot to meet the demands of regulators and consumers. Technology that integrates well with other systems will be pivotal to making quick changeovers on production lines.

Automotive manufacturers will need increased access to their data to make informed changes in production processes. This is crucial for identifying areas of improvement and calculating returns on capital investments in new equipment and components. They will need strategic partnerships to reach the next level of intelligent manufacturing with:

-

Enhanced data: collect more process data with connected sensors

-

Real-time alerts: implement Edge Computing to protect equipment

-

Predictive analytics: Build verified digital twins with Artificial Intelligence (AI)

In the past, robotic technology brought increased precision engineering and automated systems to drive process efficiency. Today, data and edge computing are enhancing production processes, safety, and quality control in real-time. Condition monitoring of robotic applications, automated traceability checks, and increased inspection technology use real-time data to better optimize and maintain critical equipment. In the future, statistical modeling and AI will incorporate predictive alerting into connected machines to improve every aspect of production. Those who lead in adopting these technologies will decide the next era of the automotive industry.

Increased production

Modular production or flexible assembly lines reduce setup times and allow for greater flexibility when changing over production lines quickly.

Increased machine efficiency

Adapt to varying vehicle models and production needs on a single assembly line through reprogramming and reconfiguration.

Improved product quality

Tasks once prone to human errors are now executed with high precision and verified for quality parts in real-time, drastically reducing defects and recalls.

Improved OEE score

Reducing downtime, minimizing errors, and optimizing resource utilization optimize efficiency as reflected in OEE scores.

Emobility

Electric vehicles (EVs) have ushered in a new era for the automotive industry. But, manufacturers need flexible production lines to accommodate hybrid vehicles on the path to electrification.

- Battery manufacturing requires increased sensor data in automated systems to ensure the correct amounts of components are mixed, while temperature and flow monitoring ensure quality throughout stages of production.

- Robots enhance precision and safety when handling the hazardous materials and precise requirements for safely assembling battery components.

Metal processing

Preparing the metal frame of a car often requires many production steps where automation plays a crucial role. From shaping to molding vehicle components, robots ensure consistency and quality. This keeps a continuous supply of parts moving down the production line. Smart sensors ensure consistency and quality from molding melted metal to casting, stamping, and pressing.

- Implementing quality checks between these steps can ensure that costly mistakes or defective parts do not continue further down the line. With many affordable error-proofing technologies today, it is easier than ever to introduce additional inspection steps.

- Process sensors provide real-time data to optimize production during the casting process to ensure the highest product quality every time.

Joining

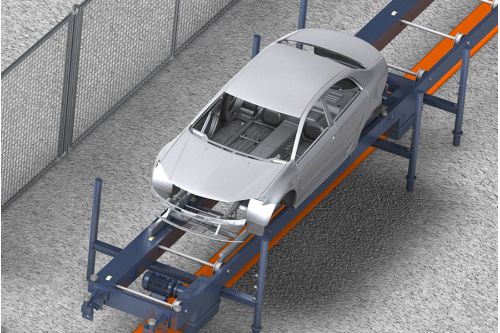

The body-in-white stage of production is crucial to developing structural integrity of the final product.

- Mobile robots use advanced sensors, vision systems, and real-time feedback mechanisms to precisely position and align components for joining. Unlike traditional fixed automation, it's fast and easy to reprogram and reposition mobile robots for various tasks. This reduces setup times and allows for greater flexibility in production lines.

- Spot welding, a crucial aspect of car manufacturing, benefits immensely from robotics technology. Industrial robots equipped with advanced sensors produce robust and consistent welds.

Painting

Robotic painting processes require significant process instrumentation to ensure high quality application and final inspection.

- The vehicle painting process requires continuous and consistent measurement of flow, pressure, and temperature.

- Implementing real-time vibration monitoring on paint spraying pumps that power the spraying robots can ensure a consistent, high quality finish. This real-time data alerts workers when a machine needs maintenance before paint quality decreases.

- RFID traceability systems can integrate with vision systems and IO-Link to log inspection checks automatically in SCADA for future reference.

Gain a competitive edge with Industry 4.0

The automotive industry is undergoing a major digital transformation. Automotive manufacturers that adopt Industry 4.0 innovations early, such as integrating edge computing, machine learning, and real-time analytics on machines will benefit from:

- Interconnected supply chains

- Increased quality and safety

- Enhanced machine efficiency

- Improved shop floor monitoring

As automotive manufacturers continue to embrace this change alongside electrification, future car production will have unmatched efficiency, quality, and safety.

What does robotic process automation (rpa) in automotive manufacturing look like?

Industrial robots and machine vision take difficult tasks once prone to human errors and execute them with high precision. They also verify for quality parts, drastically reducing defects and recalls. This saves costs in the long run, and also provides higher quality vehicles for consumers.

In automotive automation settings, robotic arms perform tasks ranging from spot welding to material removal with incredible accuracy.

While some robots operate separately from human workers for safety reasons, collaborative robots, or 'cobots,' work in parallel with human workers.

Machine vision further accentuates cobots' dexterity by enabling them to identify and handle automotive parts with precision. Sensors provide the necessary data for these robots to perform their tasks efficiently. They also provide greater awareness of a cobot's surroundings to ensure safety.

Robots in automotive manufacturing extend beyond the traditional assembly line. Advancements in die casting, CNC machining, and cutting make material removal and intricate design cuts more efficient than ever.