- Real-time maintenance

- Applications

- Submersible pump

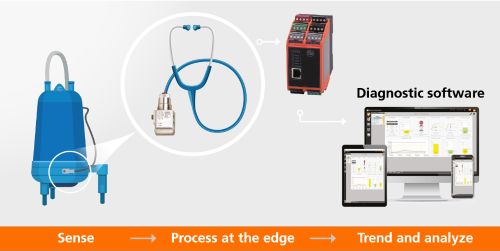

Submersible pump

Submersible pumps do the essential – but dirty work – of transporting sewage to treatment plants. Prone to blockages, ragging, and general wear and tear, pumps need to be monitored to avoid events such as overflow and environmental contamination of public and residential areas.

But how do you monitor a pump submersed in a wet well and pumping sewage? The conditions are at least described as ‘hostile’. Not only is it impractical and costly to monitor pumps manually, there are numerous occupation, health and safety concerns. However, pumps are expensive assets and difficult to replace. Which is why an online monitoring solution is ideal.

With ifm’s remote monitoring solution you can visualize the condition of your submersible pumps and diagnose issues before they become serious problems. It combines ifm’s VSE proven diagnostic technology which uses task specific submersible accelerometers. Data from this system is directly coupled to ifm’s analytic software to identify pumping issues which in turn provide current data and warnings via email or text.

| “At Lower Murray Water, we have found vibration analysis on our submersible pumps to be very beneficial. The submersible pumps and subsequently the sewer pump station were frequently receiving call-outs due to blockages. The vibration data captured facilitated quicker response time from our maintenance staff and a better understanding of the levels of vibration produced. The ifm technical team were very helpful throughout installation, setting up communications and monitoring the results.” Clinton Taylor, Mechanical Engineer – Lower Murray Water |