- Encoders

- Applications

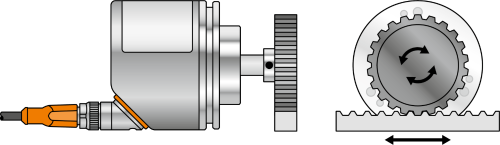

Rotational and distance movements

Example: Spindle adjustment for precise positioning using an absolute multiturn encoder.

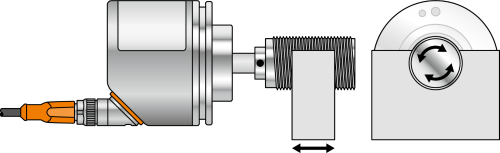

Rotational and linear movements

Example: Linear measurements using an incremental encoder on a measuring wheel.

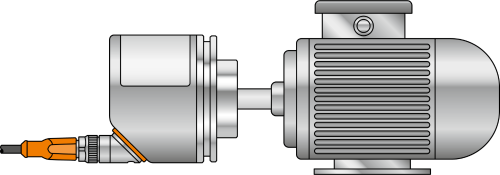

Rotational movement for speed determination

Example: Rotational speed detection of motors using an incremental encoder.

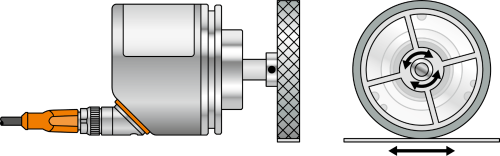

Rotational movement for position determination

Example: Positioning of rotary indexing tables for different production steps using an absolute singleturn encoder.

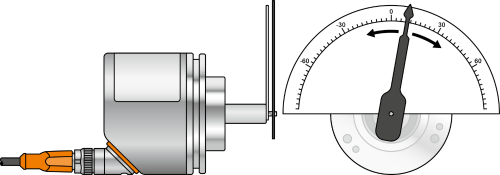

Rotational movement for angle determination

Example: Steering angle detection for operating AGVs using an absolute singleturn encoder.

Robot arm position on palletizer

Incremental encoders installed on the palletizer robot arm monitor three displacement axes: length, position and clamp. Traditional encoders have fixed resolution, so stock of multiple variants is required to meet the demands of all applications.

The resolution of ifm’s encoders is configurable from 0…10,000 pulses per revolution, as is the output (HTL or TTL) providing application flexibility and inventory reduction.

Improve product quality of high-end paper

Consistency of pulp thickness coming from the paper mill headbox is critical for uniformity of fiber and filler dispersion. This has a direct impact on the quality of the finished product.

The accurate measurement of ifm’s encoder provides 100% control of the headbox slide gate for various paper quality. The local display allows operators and maintenance personnel to have at-a-glance transparency into the process.

Conveyor belt position in a dairy

Periodic washdown exposes the encoder to excessive moisture. Traditional encoders are not designed for this environment and, when they fail, they cause unplanned downtime.

ifm offers encoders specifically designed for the harsh environment in today’s food and beverage manufacturing plants. Reduce unplanned downtime with ifm.

Storage systems

Racking systems have linear and rotating movements. For this purpose, these systems must be monitored and positioned with precision.

- Vertical monitoring

- Monitoring of position and bearing operating time - in contrast to the encoder's total operating hour counter, the bearing operating time is only counted when the shaft rotates.

AGVs and forklifts

For navigation, AGVs and forklifts require:

1. Speed monitoring in rpm

2. Steering angle

For pallet positioning, they require:

3. Fork width

4. Fork height

Cut-to-length

Cut-to-length applications require precise length measurements to accurately cut the material into sections. This family of encoders has both a digital input and output. A position sensor can be used as a trigger to reset the encoder position to zero. After the desired count is reached, an output is sent directly to the machine for the cutting operation. This eliminates time delays and resulting mechanical displacements when signals are sent through a PLC.

- Light spot

- Photoelectric sensor

- IO-Link multi-turn absolute encoder

The y-splitter EVC847 makes connection easy.

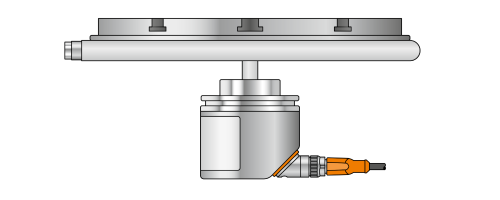

Encoders with draw-wire mechanisms attached provide highly accurate distance information between the encoder shaft and the end of the wire. The wire is wound up in a drum and the end is attached to some part of a machine that moves. As the machine moves, feedback is given to the control system about the position of the moving part.

Advantages include:

- High accuracy across the entire length of the wire (+/- 0.01%)

- Performance over long distances (up to 15 m)

Transfer systems with adjustable height are popular in the material handling industry because they provide flexibility for variable height conveyors. To measure the exact height of the transfer conveyor, a draw-wire encoder provides precise feedback to the controls system.