- Autonomous mobile robots

- Obstacle detection algorithm

- Calculating ROI

The power of 60 seconds: Improving ROI for mobile robots

There's a paradigm shift happening that can help the mobile robotics industry cross the chasm into mass adoption.

It’s the idea that, by increasing perception, you can decrease the total cost of ownership for mobile robots. And, you can improve the end user’s ROI by enough to make mobile robotics cost-effective and accessible to more companies than ever before. All it takes is 60 seconds.

Since 2012, we’ve seen a tremendous increase in mobile robotics use in manufacturing and logistics centers. And the industry is set to ramp up even more in 2024. But while we see Fortune 100, and maybe Fortune 500 companies, utilizing them, we haven’t seen mass adoption at the SME level yet.

And that begs the question: Why? What’s stopping it, and how can we impact this change?

At ifm, we approached this problem using a different metric than usual.

Rethinking cost reduction in mobile robotics

Discussions about mobile robotics and perception often center around lowering the BOM cost of the camera. That can decrease the overall cost of the robot, but let's look at the math on that.

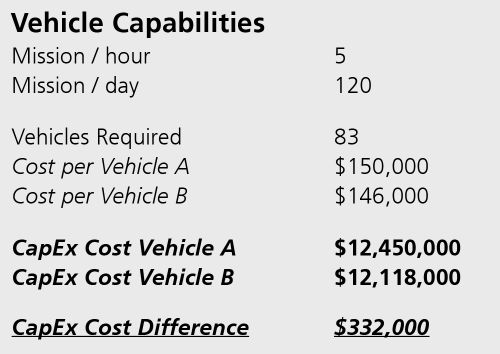

We'll talk about a use case in palette moving, specifically automated forktrucks. The end customer requires a 10,000-pallet-a-day throughput, so we’ll need roughly 83 vehicles.

To get that number, we start with missions per hour per robot. We can do five 12-minute missions per hour. That equates to 120 missions per day. Divide that by how many pallets you need to move daily, and you get to 83 vehicles.

Next, we'll use an average cost of $150,000 per automated forktruck,. The end user’s total CapEx spending is roughly $12,450,000.

That’s a hefty number. So now let’s see how reducing BOM costs reduces overall cost of ownership. We'll use the same missions per hour, the same amount of missions per day, and the same number of vehicles required for those missions. But we'll drop the cost of each robot to $146,000,000.

That’s $4000 less per unit, and it reduced the CapEx from $12,450,000 to $12,000,118. The savings are roughly $300,000 for the end user.

That’s not bad. And, it can potentially help the customer justify the cost, But is there a better way? What if you increased the overall efficiency of the robot so dramatically that it decreased the overall cost of ownership for your customer?

Lowering ownership costs by enhancing overall efficiency

Let’s look at OEE, or the overall efficiency of a machine. This metric has three components: Availability, performance and quality. If we impact the availability of the machine and impact the performance of the machine, we should make that machine more efficient. The same is true for robotics, and specifically mobile robotics.

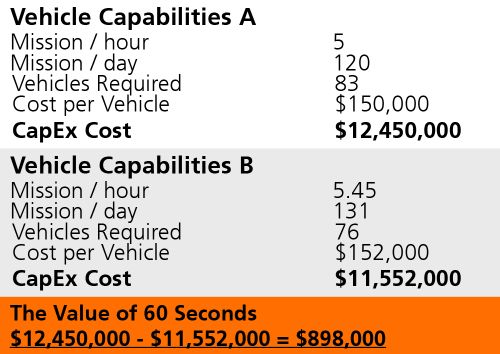

Now, let's look at the same example of 10,000 pallets a day. But instead of 12-minute missions, we're going to do 11-minute missions. We save 60 seconds, so we can now do 5.45 missions per hour and 131 missions per day per vehicle. Instead of using 83 vehicles, we use 76 vehicles.

The total cost is now $11,552,000. And if we compare that to our original $12,450,000, we’ve cut the CapEx by almost $900,000. That’s around three times the savings we got from reducing BOM cost.

How to increase completed missions and reduce total cost of ownership

So, how do you save that 60 seconds on each mission? You do it with a multi-modal approach to perception so your robot can truly understand its environment in 360 degrees. Then the robot makes better decisions and fewer unplanned stops. That’s where you see that OEE improvement and decrease in the overall cost of ownership.

It gets even more interesting: Take another look at the example where we save roughly $900,000 for that end user. Did you notice that we actually raised the price for each robot by $2000?

When you add more cameras to increase perception, you also increase the cost of each unit. But it makes the robot so much more efficient that it dramatically decreases the overall cost of ownership.

That’s what ifm is doing in the mobile robotics space, specifically with perception. We’re helping OEM’s reduce the overall cost of ownership for their customers with solutions, algorithms, and hardware pieces that impact the overall efficiency of their robots.

That’s the power of 60 seconds when it comes to ROI for mobile robotics. This level of cost savings is what can help the mobile robotics industry cross that chasm from Fortune 500 companies to SMEs and, from there, broaden its reach to the majority of companies out there today.

Gain a competitive edge

Are you ready to take your mobile robot development to the next level? Fill out the form or contact Tim McCarver directly at tim.mccarver@ifm.com.