- MVQ positioner solution

- Applications

MVQ valve positioner: Applications

Valve positioners are used for precisely moving quarter-turn valves such as ball valves and butterfly valves to a required position, based on signals from the control level indicating the desired degree of valve opening in percentage. Discover how the MVQ high-precision valve positioner compares to other valve sensors.

Increase flexibility and reduce inventory cost-effectively

Inventory costs include expenses for holding, storing, and managing inventory. Different quarter-turn valve actuators typically require distinct valve positioners and pneumatic components, complicating system integration and increasing time and risk of wiring failures. ifm’s MVQ positioner set simplifies this with an all-in-one solution, consisting of a sensing and control unit, pneumatic components, and a M12 patch-cable, significantly reducing inventory costs. Additionally, the set offers the best price-to-performance ratio on the market, making it a cost-effective choice. Designed to industrial standards, the MVQ positioner mounts directly onto the actuator shaft of ISO NAMUR actuators, ensuring high accuracy and easy installation. This enhances machine building efficiency and performance.

What is OEE?

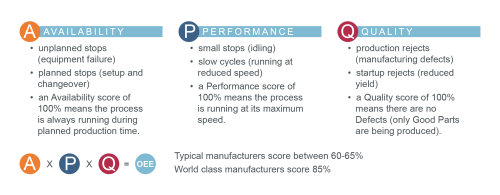

An important key indicator of Industry 4.0 implementations,Overall Equipment Effectiveness (OEE) is a measure of manufacturing productivity. Consisting of 3 factors, OEE measures machine uptime (Availability), machine speed (Performance), and non-defective products (Quality). The calculations are quite simple.

Calculating OEE

While the calculations are simple, understanding how to improve OEE can be challenging. The first step is to evaluate the losses in your process.

Typical manufacturing losses can be categorized in terms of Availability, Performance, and Quality as shown in the chart below.

|

|

In beverage production, valve positioners play a significant role in controlling the flow of liquids during filling and packaging operations. Without precise valve position control, excessive air may be introduced to the liquids during transportation via pipes and cause issues during the filling process. The MVQ positioner ensures that containers or bottles are filled accurately and consistently, minimizing product waste and optimizing production efficiency.

|

|

MVQ valve positioners are used to control valves that regulate temperature and pressure in food processing equipment such as cooking vessels, pasteurizers, and sterilizers. Precise control of these parameters is essential for ensuring food safety and quality, as well as the availability of the processing equipment.

|

|

|

Food and beverage plants are now highly automated. Automation helps to improve plant efficiency and reduce labor costs. Continuous valve feedback and positioners are integrated into automated control systems to regulate the flow of ingredients, manage production processes, and facilitate remote monitoring and control. IO-Link enabled valve positioners have very fast response times. Data is transmitted digitally without any information losses, ensuring maximum plant efficiency and product quality.

|

MVQ valve positioners can be used to control valves in water treatment processes such as filtration, disinfection, and chemical dosing. They ensure precise control over the flow of water and chemicals, helping to optimize treatment efficiency and maintain water quality.

|

Valve positioners are used in conjunction with pumps to regulate the flow of water in pumping systems. They control the opening and closing of valves to maintain desired flow rates, prevent pump overload, and optimize energy efficiency.

|

Valve positioners are utilized to control pressure-reducing valves and pressure-sustaining valves in water distribution systems. They help maintain stable water pressure levels within specified ranges, ensuring consistent service to consumers and protecting infrastructure from damage.

|

|

|

Valve positioners are essential components in the paper and pulp industry, enabling precise control, efficient operation, and reliable management of processes throughout the production cycle. They play a key role in ensuring product quality, maximizing productivity, and minimizing environmental impact.