- SMF sanitary magmeter

- Extreme testing

SMF sanitary magmeter: Extreme testing

Extensive internal and external tests ensure that the SM Foodmag can withstand the extreme conditions of day-to-day processing in the food industry over the long term. The temperature, pressure, vibration, and condensation tests described below ensure that the sanitary magnetic flow meter meets out-of-the-box accuracy and reliability specifications.

Temperature shock and temperature stress

The temperature shock test puts the sensor’s accuracy to the test when exposed to large temperature fluctuations, such as those experienced during the pasteurization process. For example, in the pasteurization of milk or highly acidic products, temperatures typically range between 72°C and 95°C before rapid cooling. This process ensures the shelf life of the products. Even after enduring 1,000 hours of continuous stress from rapid temperature changes, ranging from sub-zero to the high double-digit ºC temperatures, to simulate a decade of normal use, the measurement results must still fall within the specified accuracy band.

1,000,000 pressure cycles

Pumps and valves are required to move media from the tank to downstream processing steps. Pumps generate continuous vibrations, while quick-opening valves can create pressure peaks. The pressure peak test subjects the system to rapid pressure surges, deliberately exceeding the pressure rating provided in the data sheet. After one million cycles, the SM Foodmag undergoes leakage testing.

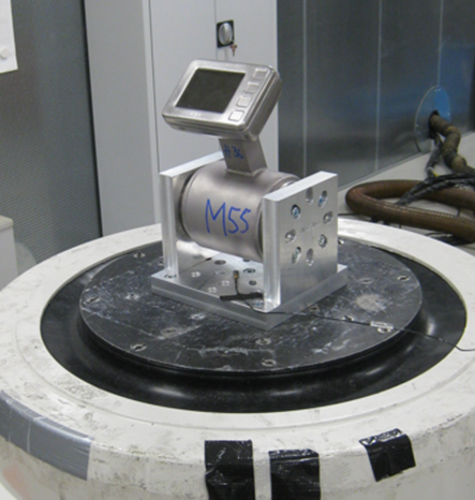

Shock & vibration

Intense shock and vibration tests are conducted along the X, Y and Z axes on a shaker over several days to ensure that external influences do not significantly impact device performance.

While the frequency band of 10....20,000 hertz (5g) is approached multiple times for each axes in the vibration test, a total of 18 different scenarios are tested in the shock resistance test with 20g (18ms).

Moisture and IP69 stress tests

During the condensation test, a cold medium passes through the pipe system and sensor while the ambient temperature remains warm. The SM Foodmag is exposed to high humidity and resulting condensation for several weeks. Additionally, the unit undergoes high-pressure washing from various angles on the display and connector, using an 80°C cleaning solution at 100 bar, to ensure that no moisture can penetrate the device.