- Discover IO-Link

- Technology

Understanding how IO-Link works

Unlike a fieldbus system, IO-Link works using a straightforward point-to-point communication method with conventional 3-wire sensor and actuator connections. IO-Link unlocks the trapped data and transmits it to higher-level systems for predictive maintenance and process quality improvements, as well as actionable insights not otherwise available.

Traditionally, the control world could only accept binary or analog signals and, therefore, only had limited information. More data required more inputs or analog cards, which are expensive and require more labor for wiring.

Today’s sensors process a lot of data, but without a pathway to the controller, it is trapped inside the sensor. IO-Link technology integrates with PLCs and IIoT technology.

IO-Link offers three general types of data that vary from sensor to sensor: Cyclic, acyclic, and events data.

Digital measurements values (Cyclic data)

Regular, automatic, and periodic exchange of process data between the IO-Link master and its connected IO-Link devices. This type of information is requested continuously from the controller and is needed to control machines or processes. The actual data is defined by the IODD and varies by device. Typical data includes:

- PDI (process data inputs)

- PDO (process data outputs)

- High-level diagnostic information

The example below shows the difference between traditional outputs available for a flow meter vs. the data available via IO-Link.

The IO-Link chip is embedded in almost all of ifm's sensors at no extra cost. Even if you are only using the analog signal or a switching output from a specific sensor, the sensor processes much more data. Without IO-Link communication, this data is trapped inside the sensor.

Traditional sensor

2 wires, user chooses ouputs

- Switching output for flow

- Switching output for temperature

- Pulse output for totalization

- Frequency output for flow

- Frequency output for temperature

- Input for counter reset

IO-Link sensor

All data over 1 wire

Cyclic data

- Flow rate

- Temperature

- Totalized volume

- Device status

Acyclic data

- Max and min flow rates

- Max and min temperatures

- Totalizer memory

- Serial number and revision verification

- Simulation mode

- Configuration parameters

Events data

- Incorrect parameters

- Sensor out of range

The IO-Link master transmits machine data, process parameters, and diagnostic information to a PLC controller or directly to a higher-level IIoT controls system. The master replaces a traditional analog input card with a digital communication path between the master and device. Up to 8 IO-Link devices, such as sensors, valves, and I/O modules, can be connected to a single master, depending on the configuration of the master.

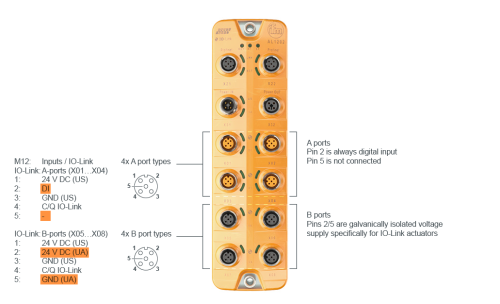

A ports are standard for most connections on IO-Link masters. B ports are used on some output devices like valve manifolds and smart LED lights when extra power is required by the devices.

On A ports, pin 2 is always used as a digital input, and pin 5 is not connected. ifm's DataLine (AL13xx) and CabinetLine (AL19xx) masters are offered with only A ports. These devices are limited to 300 mA load current per port.

On B ports, pins 2 and 5 provide an additional isolated supply voltage to connect IO-Link output devices that require increased power. With the introduction of the PerformanceLine masters (AL14xx), we can now switch loads up to 2A.

Uses of A ports and B ports on an IO-Link master

A ports on an IO-Link master are suitable for:

- Standard sensors

- RFID devices

- Alarm lights

- Low-power devices

They use 4-pin M12 connectors to provide single-system power supply 200-500 mA current capacity through a single 24VDC system (Pins 1 and 3).

Type B ports on an IO-link master are designed for high-power actuators and devices requiring additional voltage support, like valve islands. They use 5-pin M12 connectors and provide approximately 2A current capacity with auxiliary power supply.

On the B port, Pin 2 provides additional 24V+ power. Pin 5 provides auxiliary power ground, making it suitable for high-power actuators like solenoid valves.

Comparisons: IO-Link Type A ports vs. Type B ports

| Feature | Class A (Type A) Ports | Class B (Type B) Ports |

|---|---|---|

| Connectors | 4-Pin, M8* or M12 connector | 5-Pin, M8* or M12 connector |

| Current capacity | 200-500 mA | ~2A |

| Power supply | 24V Single system power supply | 24V System & auxillary power |

| Power considerations | Suitable for most sensor applications and low-power requirements | Necessary for actuator applications and higher-power requirements |

| Pin 1 | 24V direct current (DC) supply | 24V direct current (DC) supply |

| Pin 2 | Manufacturer-defined (typically addtional DI/DO channel) | Auxillary 24+V power (Ua) |

| Pin 3 | 24V direct current return | 24V direct current return |

| Pin 4 | Bi-directional serial data communication | Bi-directional serial data communication |

| Pin 5 | Not used | Auxillary power ground (GNDs) |

| Common applications | Standard industrial automation | Complex devices, higher voltage and/or current demands |

The ifm Y-path enables machine control via a PLC while offloading big data processing to higher-level systems, ensuring seamless machine operation without interference.

The PLC has been a mainstay of automation since the 1970s. It controls industrial automated equipment. With the advent of Ethernet technologies and IIoT applications, PLCs are asked to transmit more information not necessarily used for machine control.

The PLC uses less than 20% of the sensor information for machine control. Data size of this information is in bytes, and cycle time in ms. HMI, visualization computers, servers, PCs, etc. use 80% of the sensor information. Data size is in Mb and cycle time is in seconds.

But what if we could allow your sensors to talk directly to your SCADA, MES, ERP, and CMMS systems without intervention of the PLC and still send the information to the PLC for machine control?

This is now possible with the Y-path from ifm. Our IO-Link masters have a separate IIoT port with a dedicated IP address for the IT infrastructure. It does not affect the machine control side of the system. This unique approach allows you to send information and data directly where you need it.

The IODD (IO-Link Device Description) is a compact file describing how IO-Link devices communicate information to higher-level systems or controllers. It provides details about both cyclic data structure and available acyclic commands.

The IODD facilitates seamless integration of sensor devices into control systems. It offers a clear overview of communication behavior and structure.

Details on how to use the IODD can be found in the after-purchase setup and support section of this website.

Comprehensive device information

The IODD provides a comprehensive standardized description that includes:

Device identification:

- Manufacturer information

- Device type specifications

- Serial number tracking

- Model and revision details

Operational Data:

- Cyclic data structure definitions

- Available acyclic commands

- Event handling capabilities

- Parameter configuration options

Technical Specifications:

- Configurable parameters and settings

- Process data (including measurements and control signals)

- Diagnostic data and error reporting

- Communication characteristics (including data rate and format)

Key benefits and capabilities

Plug-and-work functionality

Systems instantly identify connected devices through automated device recognition. Devices self-configure without manual setup using automated configuration. Built-in diagnostic capabilities enable automated troubleshooting for faster problem resolution. You can add new devices to existing systems without significant architectural changes.

Enhanced operational flexibility

Easy device replacement works without requiring additional software tools. Seamless reconfiguration of device parameters adapts to changing needs. This provides greater flexibility in system design and expansion while delivering improved availability through faster maintenance and reduced downtime.

Superior data quality

Standardized communication protocols ensure more accurate data collection. Consistent device information enables reliable data analysis. This leads to enhanced process quality within automation environments. Detailed device information enables better decision-making across operations.

IODD file structure

An IODD is delivered as a set of files in Zip file format that includes:

- Main IODD file - Core device description and communication protocols

- Optional language files - Multi-language support for global implementations

- Optional picture files - Visual representations and diagrams

- Manufacturer declaration - Certification and compliance documentation

Finding and accessing IODDs

IODDs can be found in the IODDfinder, a comprehensive database provided by the IO-Link community. This centralized resource ensures you have access to the latest device descriptions and compatibility information for seamless system integration.

IO-link devices from ifm include their IODD information on each device's product details page.