IO-Link wiring: Overview and FAQs

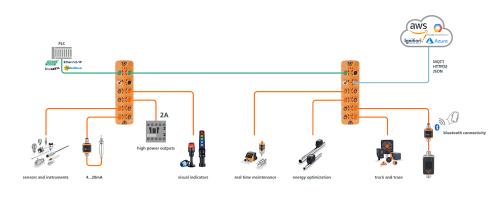

IO-Link technology enables digital communication between sensors, actuators, and control systems. IT uses scalable wire and wireless configurations that accommodate devices from simple sensors to complex actuators. This page addresses key aspects of IO-Link wiring, signal characteristics, and implementation considerations for industrial automation applications.

IO-Link typically uses 24VDC digital signals for power supply and data transmission. It uses three transmission rates: COM1 (4.8 kbit/s), COM2 (38.4 kbit/s), and COM3 (230.4 kbit/s). IO-link also transmits power alongside data on a 3-conductor cable for lower cost and simplified installation. It does not require shielded cables.

IO-Link typically uses a 3-wire cable for standard connections:

- L+ (power)

- C/Q (communication)

- L- (ground)

Some applications use 4-wire or 5-wire cables depending on the port class and specific functionality requirements.

A and B ports

Class A ports generally use 4-pin M12 connectors, while Class B ports use 5-pin M12 connectors to provide additional auxiliary power for high-current devices like solenoid valves.

The 3-wire foundation reflects IO-Link's design philosophy of leveraging existing sensor and actuator connection technology while adding digital communication capabilities.

In Class A configurations, the fourth wire (Pin 2) is often manufacturer-defined and can serve as an additional digital input/output channel.

Class B ports use the fifth wire (Pin 5) alongside Pin 2 to create an auxiliary power circuit (Ua and GNDa) that operates parallel to the main system power. This configuration enables support for devices requiring up to 2A current compared to the 200-500mA limitation of 3-wire Class A systems.

This scalable wire configuration allows IO-Link to accommodate everything from simple sensors to complex actuators while maintaining backward compatibility with traditional binary devices.

Cable specifications

The IO-Link standard specifies unshielded, standard cables up to 20 meters in length using 3 or 4-wire configurations. Standard M8 and M12 connectors* with type A coding and IP65/67 protection are used for connections.

The connector standardization, combined with unshielded cable compatibility, creates a cost-effective solution that maintains industrial-grade durability while supporting both Class A (4-pin) and Class B (5-pin) port configurations for different power requirements.

Unlike traditional analog sensor systems that are susceptible to electrical interference and signal degradation, IO-Link transmits data digitally using 24V pulses in a non-return-to-zero (NRZ) format on the C/Q line.

The protocol's half-duplex communication at three standardized baud rates (COM1: 4.8k, COM2: 38.4k, COM3: 230.4k) ensures reliable data transmission without the electromagnetic interference protection typically required by shielded cables.

IO-Link wireless technology exists as part of the official IO-Link specification developed by the IO-Link Consortium. IO-Link was originally designed around wired connections to leverage existing bus systems within facilities. Several companies added wireless options with more technologies in development.

A wireless system maintains full compatibility with existing wired IO-Link infrastructure. The typical 20-meter range between master and device for wireless IO-link is ideal for applications involving rotating machinery, AGVs (Automated Guided Vehicles), robots, and other moving systems where traditional cabling is impractical or prone to wear.

Wireless IO-Link facts and specifications

-

The wireless system can support a 20x20-meter production cell with up to 120 wireless devices using three wireless masters each supporting up to 40 devices.

- The wireless system uses the open 2.4 GHz ISM band, divided into 80 1MHz channels, with virtual point-to-point connections realized through time and frequency division multiplexing.

- Eight devices are grouped into tracks (TDM), with 5 tracks per master transmitted in parallel at a 5ms cycle time.

- This architecture ensures deterministic communication with a packet error rate of 10⁻⁹, making it suitable for real-time factory automation applications.

- The frequency hopping mechanism and blacklisting capabilities ensure coexistence with other wireless systems in the industrial environment.

Wired vs. wireless IO-Link

Wired IO-Link excels in real-time applications requiring continuous, guaranteed data delivery. Wireless IO-Link is better for applications where periodic updates are sufficient and installation flexibility is prioritized over real-time performance.

Using a wireless IO-Link connection reduces installation costs and time. However, a wireless connection relies on battery power. This limits the amount of real-time data the system can transmit to preserve battery life.

A wireless IO-Link system still leverages an existing bus system to capture data from every cycle through the PLC. But it won’t transmit all the data in real-time.

The standard IO-Link voltage for power supply and communication medium between masters and devices is 24V DC. However, IO-link masters can supply voltage from 20V to 30V. IO-link devices (sensors and actuators) function within a range of 19V to 30V.

These ranges offer flexibility for different industrial applications while maintaining the 24V nominal operating standard.

IO-Link Class A ports use a 3-wire interface (L+, C/Q, L-) to deliver power and digital communication. Class B ports can provide different, isolated voltage levels through pins 2 and 5 (Ua and GNDa) than the main system power on pins 1 and 3.

Communication uses nonreturn-to-zero (NRZ) encoding on the C/Q line. In IO-Link mode, a logic 0 is represented by the CQ line being at L+ (nominally 24V), and a logic 1 by CQ at L- (0V).

However, the standard defines a logic high as any voltage above 13V and a logic low as any voltage below 8V.

Devices must become operational within 300ms after the L+ voltage exceeds 18V, ensuring reliable startup across the specified voltage range.

Establishing an IO-Link connection requires:

- An IO-Link master device that acts as the gateway to a control system

- Standard 3-wire sensor/actuator cables with M8 or M12 connectors*

- IO-Link devices, usually sensors, RFID readers, or actuators like valves

Each IO-Link device connects to the master using the 3-wire cable (no special IO-Link cable is required). The cable accommodates signal and data transmission and power, all in the same connection. The devices and master communicate using the standardized IO-Link communication protocol.

Next, the IO-Link master acts as the gateway by connecting the control system, such as a PLC, via a fieldbus or Ethernet connection. The master translates the IO-Link communication protocol to one that the PLC uses. The master now handles all communication between the PLC and IO-Link devices.

Key features of the IO-Link setup are:

- Dedicated, reliable connection between each device

- Access to process and diagnostic data from all connected devices

- Consistent connections using standard M8 or M12 connectors*

- Minimal wiring with one cable handling power, ground, and communication

Connecting to a PC via USB

For configuration and testing purposes, IO-Link devices can also connect to a PC using a USB-based IO-Link interface. This setup allows users to configure sensor parameters and read process values before installation or during field service.

The USB interface acts as a single-port IO-Link master, converting USB communication to the IO-Link protocol. Most interfaces can power sensors directly from the USB connection without requiring a separate power supply. Field configuration with a laptop is particularly convenient. Status LEDs typically provide visual feedback for troubleshooting and system status monitoring.