- Encoders

- Incremental encoders

Incremental encoders: Tracking and flexibility for high-speed applications

Incremental encoders produce a specific number of pulses per revolution, allowing for precise position tracking of the connected shaft when referenced from a starting or home position. If the power supply is interrupted, the encoder must perform a homing run upon restart to accurately determine the shaft’s reference (home) position. When using incremental encoders with IO-Link, this homing run is not required and the encoders act like absolute encoders.

These rotary encoders can operate in HTL (High-Threshold Logic) mode, which means they operate with a stronger signal and larger change in voltage between the high and low states. This makes them ideal for long cable lengths or areas with potential for electrical noise.

The encoders can also operate in TTL (Transistor-Transistor Logic) mode, outputting a square wave signal typically between 0 and 5 VDC. Because of the lower voltage swing, switching frequency is faster and these outputs are suitable for speeds up to 12,000 rpm. Users can program the resolution flexibly between 1 and 10,000 increments to reduce variant complexity.

Incremental encoders are ideal for fast applications, detecting any changes in angular position.

Some incremental encoders from ifm are IO-Link enabled, providing the benefit of retaining its current position even during a power outtage.

Without IO-Link: When used conventionally, the encoder does not reference the current position. As a result, the PLC must calculate relative values for angular position, speed, or direction of rotation.

With IO-Link: The encoder can retrieve more information and knows its current position without PLC involvement. It maintains this position even during a voltage drop, behaving like an absolute single-turn encoder by outputting an absolute position value within one revolution.

Robot arm on palletizer

Incremental encoders installed on the palletizer robot arm monitor three displacement axes: length, position and clamp. Traditional encoders have fixed resolution, so stock of multiple variants is required to meet the demands of all applications.

The resolution of ifm’s encoders is configurable from 0…10,000 pulses per revolution, as is the output (HTL or TTL) providing application flexibility and inventory reduction.

Improve product quality of high-end paper

Consistency of pulp thickness coming from the paper mill headbox is critical for uniformity of fiber and filler dispersion. This has a direct impact on the quality of the finished product.

The accurate measurement of ifm’s encoder provides 100% control of the headbox slide gate for various paper quality. The local display allows operators and maintenance personnel to have at-a-glance transparency into the process.

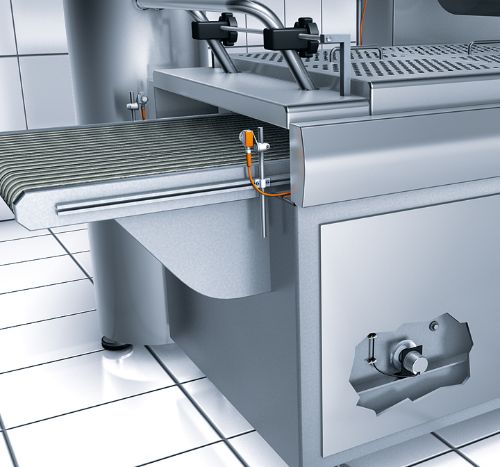

Conveyor belt position in a dairy

Periodic washdown exposes the encoder to excessive moisture. Traditional encoders are not designed for this environment and, when they fail, they cause unplanned downtime.

ifm offers encoders specifically designed for the harsh environment in today’s food and beverage manufacturing plants. Reduce unplanned downtime with ifm.

Incremental encoders provide an output of one pulse (square wave cycle) for each increment on the encoder.

The number of square waves (pulses) generated in one full rotation of the shaft is referred to as resolution. For example, an encoder with a resolution of 1024 will generate 1024 pulses when the shaft is rotated 360°.

As the resolution increases, the number of pulses increases.

When referenced to a starting point, the number of pulses generated gives feedback on the position of the shaft. When power is cycled, the encoder does not retain the position value. However, when used with IO-Link, ifm's incremental encoders do retain the position information when power is lost.

Basic incremental encoders normally have 3 output channels: A, B and Z. Channels A and B are offset by 90° and can be used to monitor direction of shaft rotation. If channel A leads channel B (top drawing), the shaft is rotating clockwise and the increment is counting up. If channel B leads channel A (bottom drawing), the shaft is rotating counter clockwise and the increment is counting down.

The Z channel is also known as the zero or index channel. It provides a single pulse per shaft revolution and it establishes the home position for the encoder. This ensures accurate position tracking.

| Type | Housing Ø | Solid shaft Ø | Hollow shaft Ø | Resolution | Features |

|---|---|---|---|---|---|

PerformanceLine |

58 mm |

6 mm 10 mm |

3/8" 12 mm 15 mm 5/8" |

Up to 10,000 pulses per revolution |

|

BasicLine |

36.5 mm 58 mm |

6 mm 10 mm |

6 mm 3/8" 12 mm 15 mm 5/8" |

|

|

WetLine |

58 mm |

6 mm 10 mm |

3/8" 12 mm 15 mm 5/8" |

|

PerformanceLine

PerformanceLine encoders have an integrated signal evaluation for speed monitoring, counter functions and detection of the direction of rotation. They provide easy setting and position value indication by means of display and operating keys with intuitive menu navigation. Diagnostic and parameter data are reliably transferred via IO-Link. Ready for IIoT.

- Encoder mode: Display position based on the resolution set via IO-Link.

- Counter mode: Count up to the maximum value set via IO-Link.

- Speed monitor mode: Monitor revolutions per minute and frequency.

BasicLine

Cost effective version without display.

- Programmable

- Axial or radial cable entry

- TTL or HTL output

- Clockwise / counterclockwise counting direction

WetLine

ifm’s stainless steel incremental encoders, for applications such as conveyor belt synchronization, ensure longer maintenance intervals in harsh environments. The increased protection rating IP 67 qualifies them for use in wet areas in the food industry.

- Stainless steel housing and high ingress protection at the shaft

- Laser-etched label

- IO-Link enabled

- Axial or radial M12 connector