- Encoders

- Absolute encoders

Absolute encoders: Maintain precise position even when unpowered

Single-turn and multi-turn absolute encoders are essential components in modern industrial automation, providing precise position feedback for various applications. Single-turn encoders measure the position within one revolution, making them ideal for applications where the position needs to be reset after each turn, such as in robotics or conveyor systems. Multi-turn encoders, on the other hand, can track the position over multiple revolutions, which is important for applications requiring continuous position tracking, like in elevators or wind turbines.

With absolute encoders, the absolute position value of the shaft is available even after power loss. Unlike conventional incremental encoders, they require no homing run to the start or home position after a power failure.

The integration of IO-Link technology enhances these encoders by enabling seamless communication with control systems, allowing for real-time data exchange and diagnostics.

In general, the use of IO-Link in absolute encoders offers several advantages. It simplifies wiring and reduces installation costs by using standard 3-wire connections. Additionally, IO-Link provides advanced diagnostic capabilities, enabling predictive maintenance and reducing downtime. This technology allows for easy parameterization and configuration, ensuring that the encoders can be quickly adapted to different applications. Absolute encoders with IO-Link improve operational efficiency, accuracy, and reliability in industrial automation systems.

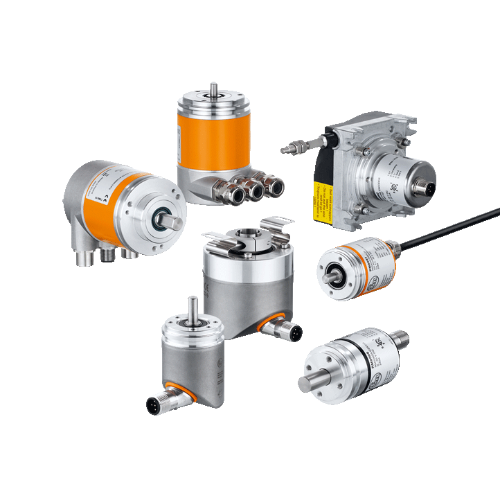

ifm's IO-Link encoders specifically expanded to include multi-turn absolute versions. They will retain absolute position even if the shaft rotates when power is removed. All models have a total resolution of 31 bits (16 bits per rotation, 15 bits number of rotations). Diagnostic information, including bearing operating time, is available via IO-Link for predictive maintenance. A digital input and output allows direct control of machine processes avoiding mechanical offset issues in cutting operations due to delays created by detouring through a PLC. Compared to standard fieldbus multi-turn encoders, wiring is simplified and shielded cables are not required.

Storage systems

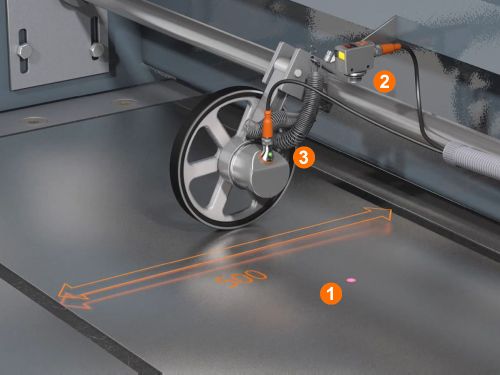

Racking systems have linear and rotating movements. For this purpose, these systems must be monitored and positioned with precision.

- Vertical monitoring:

Accurate vertical positioning helps prevent errors that could lead to misplaced items, reducing the time and effort needed to locate and retrieve products.

By knowing the exact position of each item, the system can quickly and accurately move to the desired location, minimizing downtime and increasing throughput. This precision is particularly important in high-density storage environments where space is limited and the margin for error is small.

Accurate vertical positioning helps avoid collisions and mechanical failures that could occur if items are not correctly aligned. This not only protects the goods being stored but also ensures the longevity and smooth operation of the storage and retrieval equipment.

-

Shaft position and bearing operating time

Precise shaft position monitoring ensures accurate and reliable movement of the racking system mechanisms. This precision is essential for the correct placement and retrieval of items, minimizing errors and increasing the efficiency of the system.

Tracking bearing operating hours helps in predictive maintenance. By monitoring the usage and wear of bearings, maintenance can be scheduled proactively before failures occur. This reduces unexpected downtime and extends the lifespan of the equipment, leading to more reliable and cost-effective operations.

AGVs and forklifts

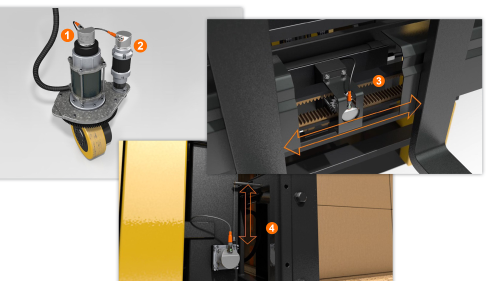

For navigation, absolute encoders are used with AGVs and forklifts to monitor speed and steering angle due to their reliability and precision.

For pallet positioning, they are used to monitor fork width and fork height.

- Speed monitoring in rpm

For speed monitoring, absolute encoders measure the rotational position of the vehicle’s wheels or motor shafts. By tracking the exact position over time, the system can calculate the rotational speed (rpm) accurately. This data is used to control the vehicle’s speed, ensuring smooth acceleration and deceleration, and maintaining consistent operation. - Steering angle

Absolute encoders provide precise feedback on the position of the steering mechanism. This allows the control system to know the exact angle of the wheels at any given moment, which is essential for navigating tight spaces and making precise turns. The encoder’s ability to retain position information even after power loss ensures that the vehicle can resume operations without needing recalibration, enhancing reliability and efficiency in automated environments. - Fork width

Absolute encoders measure the distance between the forks. This is required for handling different pallet sizes and types accurately and efficiently. By providing real-time data on the fork width, the system can automatically adjust the forks to the correct width for each pallet, ensuring secure and stable handling. - Fork height

Absolute encoders monitor the vertical position of the forks. This is important for stacking pallets at different heights and for retrieving pallets from various levels. The encoder ensures that the forks are positioned at the correct height, preventing collisions and ensuring smooth and safe operations. The precise height data also helps in optimizing the stacking process, making it more efficient and reliable.

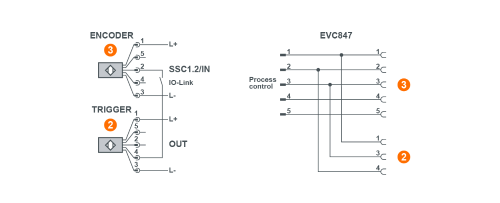

Cut to length

Cut-to-length applications require precise length measurements to accurately cut the material into sections. This family of encoders has both a digital input and output. A position sensor can be used as a trigger to reset the encoder position to zero. After the desired count is reached, an output is sent directly to the machine for the cutting operation. This eliminates time delays and resulting mechanical displacements when signals are sent through a PLC.

- Light spot

- Photelectric sensor

- IO-Link multi-turn absolute encoder

The y-splitter EVC847 makes connection easy.

ifm's absolute encoders use magnetic technology.

Magnetic encoders use Hall-effect sensors to detect rotary movements. The sensors detect the orientation of a permanent magnet attached to the shaft. A microprocessor then calculates the angle of rotation of the shaft from the sensor signals.

- High resolution and accuracy but smaller package and lower price point

- Fewer components for more robust solution

- Programmable resolution and output

- Variants available with IO-Link for process transparency

1 = Magnet, 2 = Hall sensor, 3 = Wiegand wire

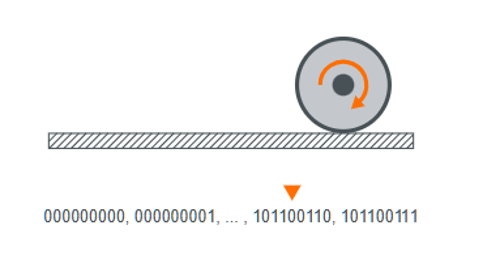

As opposed to incremental encoders, absolute encoders provide a specific numerical value for each angular position of the shaft.

Single-turn encoders

Single-turn encoders divide a mechanical revolution (0…360°) into a certain number of measure steps determined by the resolution of the encoder.

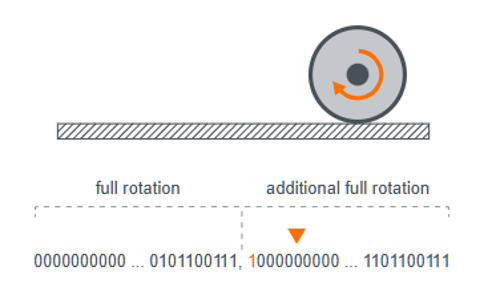

Multi-turn encoders

Multi-turn encoders provide a unique coded value consisting of the location on the disc (resolution) and the location of the gear train (revolutions).

Common absolute encoder resolutions include 10-bit (1024 steps), 11-bit (2048 steps), 12-bit (4096 steps) and 13-bit (8192 steps). When combining resolution with revolutions, unique steps can be 24-bit up to 31-bit.

Absolute encoders are available with parallel, serial or fieldbus outputs to transmit shaft positon data.

- Parallel outputs require an output for each bit of information. For example, a 12-bit parallel output requires 12 separate outputs to transmit the data.

- Synchronous Serial Interface (SSI) is a means to transmit encoder position data serially.

- Various fieldbus options are available for absolute encoders. ifm encoders specifically are available with ProfiNet, Profibus and CANopen interfaces.

- ifm offers IO-Link enabled encoders to provide diagnostic information and easy integration into your controls architecture.

| Type | Housing Ø | Solid shaft Ø | Hollow shaft Ø | Resolution | Features |

|---|---|---|---|---|---|

CAN interface |

36.5 mm 42 mm 58 mm |

6 mm 10 mm 12 mm |

N/A |

24-bit 25-bit |

|

All absolute |

36.5 mm 42 mm 58 mm |

6 mm 10 mm 12 mm |

12 mm 15 mm |

24-bit 25-bit 29-bit 31-bit |

|

WetLine |

36.5 mm 42 mm 58 mm |

10 mm |

12 mm |

24-bit 29-bit 31-bit |

|

CAN interface absolute encoders

These encoders provide precise position data directly to the CAN bus, allowing for efficient and reliable communication between multiple devices in a network.

- High speed data transmission

- Consistent and accurate transfer of measurements

All absolute encoders

Absolute encoders are available with parallel, serial or fieldbus outputs to transmit shaft position data.

- Absolute encoders with parallel outputs require an output for each bit of information.

- Data on the position of the encoder can also be transferred via the synchronous serial interface (SSI).

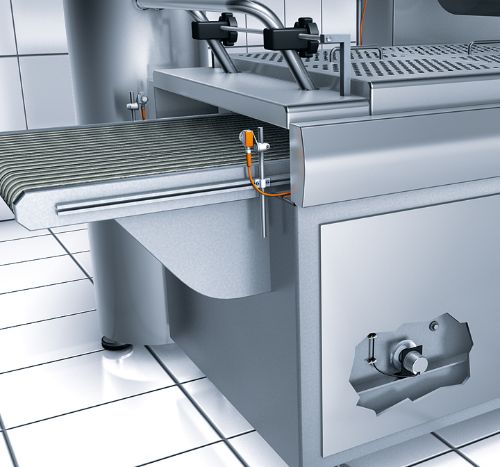

WetLine absolute encoders

ifm’s stainless steel absolute encoders, for applications such as conveyor belt synchronization, ensure longer maintenance intervals in harsh environments. The increased protection rating IP 69K qualifies them for use in wet areas in the food industry.

- Stainless steel housing and high ingress protection at the shaft

- Laser-etched label

- IO-Link enabled

- Axial or radial M12 connector