- Supply Chain Management

- Sales & Operations Planning

- Factory Optimization Excellence (FOX)

Factory Optimization Excellence (FOX)

Optimize manufacturing in SAP with AI-driven production planning

FOX is an AI-driven solution designed to enhance production planning within SAP environments. It streamlines manufacturing operations by integrating comprehensive data analysis and advanced planning techniques to create the most optimal production plan.

By optimizing resource allocation and production schedules, FOX provides manufacturing companies with a powerful tool to optimize their operations, reduce costs, and improve overall efficiency.

Struggling with bottlenecks stifling your production flow?

Eliminate bottlenecks with FOX's comprehensive work center analysis.

Facing complexities in dependency management across work centers?

Simplify complex dependencies with our dynamic pegging system.

How FOX works

Step 1: Data selection

Choose relevant production data for optimization.

Step 2: Pegging

Identify crucial predecessor and successor relationships.

Step 3: Constraints identification

Highlight and account for any production constraints.

Step 4: Optimization

Run the data through FOX's AI optimizer.

Effective work center planning with FOX

-

Comprehensive material tracking: Ensure all necessary materials and parts are identified and scheduled to arrive exactly when and where they are needed, minimizing delays and maintaining the momentum of production.

-

Strategic downtime management: Intelligently schedule rest and buffer times to maximize productivity without compromising machinery health or workforce welfare.

-

Precise scheduling: Coordinate material deliveries and workforce assignments to ensure that each work center operates at peak efficiency, streamlining operations and reducing bottlenecks.

-

Deadline adherence: Prioritize and sequence orders to meet stringent deadlines, supporting your commitment to reliability and customer satisfaction.

-

Integrated process mapping: Understand and manage dependencies across upstream and downstream processes, ensuring a cohesive and uninterrupted production flow.

FOX benefits

Continual production utilization

Increased throughput

Improved delivery readiness

Reduced manufacturing costs

- Simultaneously addresses various optimization objectives

- Automatically adjusts order sequences for better workflow and resource allocation

- Allows you to set and adjust order priorities

- Enables immediate recalculations so plans remain relevant and efficient

Applicable industries

Automotive

Challenges: Just-in-time production models, complex supplier networks, and rigorous quality and safety standards.

FOX Benefits: Ensure on-time delivery with dynamic scheduling, maintain quality while reducing costs, and adapt swiftly to new market trends.

Aerospace and defense

Challenges: Managing complex assemblies, long lead times, and upholding strict quality requirements.

FOX Benefits: Streamline project management, ensure on-time delivery of components, and maintain the highest standards of quality and compliance.

Chemicals

Challenges: Handling hazardous materials, adhering to strict environmental regulations, and managing complex chemical processes.

FOX Benefits: Reduce environmental impact and optimize production processes, ensuring a safer, more sustainable, and efficient chemical manufacturing operation.

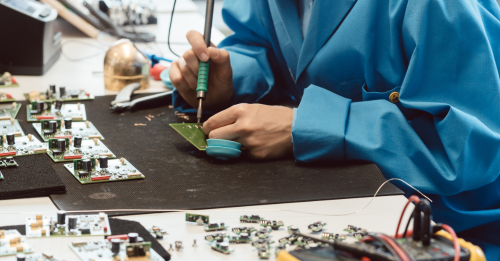

Electronics

Challenges: Short product lifecycles, high consumer expectations, managing complex component supply chains, and reducing time-to-market.

FOX Benefits: Respond quickly to market changes with agile production planning, reduce lead times, and manage product variations more effectively.

Schedule your live demo today

Discover how Factory Optimization Excellence (FOX) can streamline your manufacturing processes using AI. Schedule a personalized demo with our expert team to explore our solution's full capabilities and see how it can benefit your business.

- See FOX in action: Get a comprehensive walkthrough of our key features and functionalities tailored to your specific needs.

- Ask the experts: Have your questions answered by our knowledgeable team and learn how FOX can address your unique challenges.

- Tailored recommendations: Receive personalized insights and recommendations based on your business requirements and goals.

Contact us to schedule your demo

- Email: usa@ifm.com

- Phone: +1 (470) 909-4011

- Schedule online: Submit the form below