- Supply Chain Management

- Sales & Operations Planning

- Inventory Management

Supply Chain Excellence (SCX) for Inventory Management

Dynamically manage safety stock, MRP strategies, and replenishment settings for smarter inventory decisions inside SAP.

SAP provides robust tools for inventory planning but configuring and maintaining them effectively remains a challenge for many organizations. SCX for Inventory Management analyzes real consumption patterns, lifecycle stages, and segmentation characteristics to dynamically align planning strategy with operational execution. The result: lower inventory costs, improved service performance, and faster response to change — all inside your existing SAP environment.

Connect your planning strategy to real execution results

Reduce manual configuration with intelligent parameter matching and simulations.

Dynamically optimize planning based on demand variability and material lifecycle.

Achieve greater service levels without inflating inventory.

Stay within SAP: No external tools, no data silos, no complex integrations.

Key features

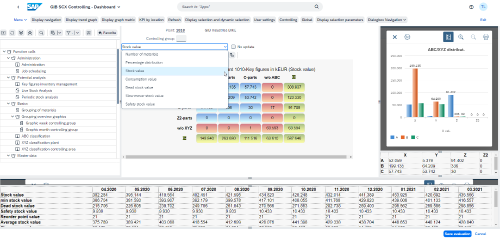

ABC/XYZ analysis

Tailor planning strategies by classifying items based on value and demand variability. Prioritize forecasting and stock control based on item criticality and behavior patterns.

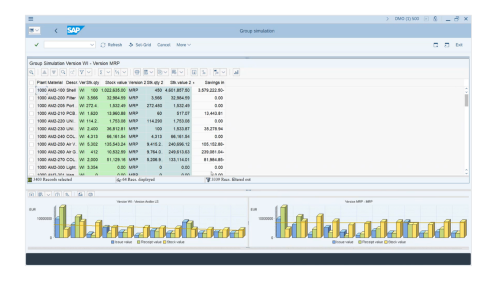

Simulation and scenario analysis tools

Run real-time what-if simulations across SAP to evaluate changes in demand, lead times, or supply disruptions. Make better decisions with visual, risk-aware planning models.

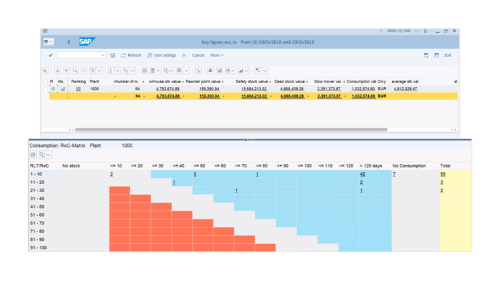

Key figures

Track essential inventory KPIs — like stock value, average consumption, issue frequency, and replenishment velocity — to optimize service levels, reduce costs, and eliminate blind spots.

Material segmentation

Segment materials dynamically by lead time, turnover rate, or role in production. Apply targeted policies for forecasting, procurement, and stocking based on lifecycle and usage.

Replenishment Lead Time (RLT) Monitor

Get full visibility into supplier lead times and detect early or delayed deliveries in real time. Adjust safety stock buffers and procurement timing with confidence.

Range of Coverage (RoC)

Measure how long current inventory will meet future demand. Get alerts on potential overstock or stockout risks and adjust planning horizons accordingly.

ABC/XYZ analysis: Align planning with item value and demand behavior

Focus efforts on the most critical inventory items

- AX items: High-value items with predictable demand — Focus on accurate forecasting and tight inventory control to minimize holding costs without risking availability. Think a common brake pad for a high-volume vehicle model.

- AY items: High-value items with variable demand — Monitor frequently and adjust safety stock dynamically to balance cost and service level. Think hospital-grade surgical kits with inconsistent consumption patterns.

- AZ items: High-value items with unpredictable demand — Maintain buffer stock and build flexibility into your supply chain to mitigate risk. Think custom-configured machine components with long lead times.

- BX, BY, BZ items: Medium-value items across different demand variability levels — Control inventory via periodic reviews, reorder point adjustments, and hybrid replenishment models based on recent demand trends. Think protective packaging for mid-range product (BX), seasonal promo items with inconsistent popularity (BY), and standard electrical components with infrequent orders (BZ).

- CX, CY, CZ items: Low-value items with varying demand patterns — Streamline planning and avoid over-managing items with minimal financial impact. Think fasteners, labels, or SKU's used across multiple SKUs (CX), branded swag for marketing campaigns (CY), and obsolete spare parts with unpredictable usage (CZ).

ABC/XYZ use cases

Inventory optimization

Align service levels and stock policies with item importance and variability, freeing up cash from low-priority inventory.

Demand forecasting

Apply differentiated forecasting models based on demand patterns to improve accuracy and prevent overstock.

Cost management

Avoid costly one-size-fits-all policies by focusing planning effort where it delivers the most ROI.

Multi-level simulation: Model scenarios, minimize risk, and optimize planning decisions

Test how supply chain decisions play out across demand, inventory, capacity, and procurement levels

- Evaluate risk under hypothetical changes—like fluctuating demand, extended lead times, or supply interruptions.

- Adjust key parameters (e.g., safety stock, order quantities, production timing) and see their impact before implementation.

- Compare stocking strategies to find the optimal balance between service levels, carrying costs, and response time.

- Test production schedules to improve capacity utilization and align with fluctuating demand patterns.

Simulation and scenario analysis use cases

Demand fluctuation management

Model inventory and production strategies under high-variability scenarios to maintain service levels without overstocking.

Supplier reliability

Simulate late shipments and test alternative sourcing strategies or buffer stock requirements to mitigate risk.

New product introduction

Analyze the impact on existing capacity, stock requirements, and procurement needs to ensure smooth, cost-effective launches.

Key figures: Turn raw SAP data into actionable performance indicators

Spot inefficiencies, mitigate risks, and guide strategic improvements

- Monitor inventory value, turnover, and service readiness in real time.

- Detect inefficiencies in consumption, replenishment, or supplier delivery performance.

- Forecast more accurately by tracking historical patterns and RoC (Range of Coverage) insights.

- Optimize working capital by identifying where to reduce or reallocate inventory.

Stock key figures

- Stock value: Understand the financial weight of your inventory over time.

- Average stock: Gauge typical stock levels for planning accuracy and cost control.

- Maximum and minimum stock: Identify stock level extremes with the highest and lowest stock levels recorded.

Consumption key figures

- Consumption value: Track actual material usage by value to detect shifts or spikes in demand.

- Average consumption: Smooth volatility in planning by leveraging reliable averages.

Issue key figures

- Issue value: Measure turnover to evaluate inventory health and planning accuracy.

- Frequency of issues: Spot usage trends and set replenishment cycles accordingly.

Receipt key figures

- Receipt value: Analyze incoming inventory by spend to align with budget goals.

- Number of receipts: Evaluate supplier cadence and inbound logistics performance.

Material segmentation: Target the right strategies to the right materials

Segment inventory based on real operational characteristics — such as usage rate, lead time, value, or demand variability

- Define up to three custom segmentation characteristics tailored to your business.

- Group materials by attributes such as turnover, supplier reliability, or lifecycle stage.

- Integrate segmentation insights with key figures and other analytics for a complete view.

- Automatically update classifications as business conditions change so plans remain current.

Material segmentation use cases

Inventory optimization

Group materials based on turnover rates and adjust inventory policies accordingly. Example: Fast-turn raw materials receive more frequent replenishment cycles, while slow-moving spare parts are ordered less often to avoid overstock.

Procurement strategy

Classify materials based on supplier lead times and reliability to develop tailored procurement strategies. Example: Items from long-lead-time suppliers are flagged for higher safety stock, while locally sourced materials are managed with leaner buffers.

Demand forecasting

Segment materials by demand patterns to apply appropriate forecasting models. Example: Seasonal products (e.g., winter equipment) are grouped separately, ensuring forecasting models account for cyclical demand patterns.

Production planning

Categorize materials by their role in the production process (e.g., raw materials, work-in-progress, finished goods). Example: Critical raw materials are prioritized in scheduling to avoid production stoppages, while finished goods are optimized for customer delivery performance.

Replenishment Lead Time (RLT) Monitor: Turn supplier performance into planning certainty

Ensure replenishment strategies are based on actual supplier behavior

- Track the actual duration of every replenishment, not just planned lead times.

- Spot chronic supplier issues and variances before they disrupt operations.

- Receive alerts when lead times deviate from agreed standards.

- Benchmark suppliers on reliability and responsiveness, fueling stronger negotiations.

RLT Monitor use cases

Stock level maintenance

When a supplier consistently delivers early or late, planners adjust replenishment policies to prevent excess stock or shortages.

Safety stock calculation

Safety stock buffers are dynamically recalculated based on real lead time variability rather than static assumptions.

Supplier evaluation

Suppliers with consistent on-time delivery are rewarded with leaner policies; unreliable suppliers trigger buffer increases or dual sourcing.

Negotation tool

Procurement teams use factual lead time performance data in negotiations, driving accountability and improved terms.

Range of Coverage (RoC): Anticipate stock issues before they happen

Know not just what you have today, but how long it will last against actual demand

- Assess how long current inventory will last, based on real consumption and requirements.

- Compare inventory coverage against future forecasts and sales orders.

- Receive alerts for potential stockouts or overstock situations before they hit operations.

- Drill down into specific items or periods to investigate the root cause of why coverage is at risk.

RoC uses cases

Inventory optimization

A planner sees coverage for a critical component dropping below 10 days and triggers a replenishment order early, avoiding a production stop.

Demand Planning

A forecast for a seasonal product shows demand spikes in 8 weeks. RoC alerts the planner that current stock will fall short, prompting procurement to place orders now.

Supply chain resilience

RoC shows declining coverage across multiple SKUs tied to a key supplier. Leaders escalate supplier discussions and evaluate secondary sourcing before shortages occur.

Frequently asked questions

Schedule your live demo today

Discover how SCX for Inventory Management can optimize your inventory strategies within SAP. Schedule a personalized demo with our expert team to explore our solution's full capabilities and see how it can benefit your business.

- See SCX for Inventory Management in action: Get a comprehensive walkthrough of our key features and functionalities tailored to your specific needs.

- Ask the experts: Have your questions answered by our knowledgeable team and learn how SCX for Inventory Management can address your unique challenges.

- Tailored recommendations: Receive personalized insights and recommendations based on your business requirements and goals.

Contact us to schedule your demo

- Email: usa@ifm.com

- Schedule online: Submit the form below