- moneo IIoT platform

- Improve manufacturing processes

- Optimise energy consumption

Optimise energy consumption

ifm develops customised energy monitoring solutions for you - tailored to your requirements. This will not only help you drive forward the digitalisation of your company, but also discover new potential for saving energy and significantly reducing costs.

Energy optimisation in practice - inspiring use cases

Measuring energy consumption and waste at machine level

Lower annual energy costs

Increase your energy efficiency and save up to 50 % a year - a third of this without high investments.

Tracking total costs

Gain complete transparency of the costs per product and immediately discover potential for targeted process optimisation.

Tracking energy consumption over time

Visualise wasted energy such as compressed air leaks and optimise your consumption by tracking at machine or zone level.

Potential areas for energy savings

There is potential to save energy in every company - from simple measures such as energy-efficient light bulbs to large investments such as refurbishing existing equipment. These areas offer particularly high potential for saving energy in the industry:

Leakage monitoring from the compressor to the machine

Compressed air is used in almost all industries. From the forge to the clean room - leaks can occur in any compressed air network.

Monitoring is easy with ifm: Whether flow rate measurement, pressure measurement, temperature monitoring or total quantity. You can monitor all relevant process data with just one cable and one sensor. Benefit from the numerous advantages of SD sensors with IO-Link.

Real-time analysis

Identify long-term trends about consumption or fluctuations of air pressure with the SD sensors and optimise processes.

Less hardware

IO-Link transmits 4 values via 1 cable. Without additional sensors, cables or pipe fittings.

Wireless monitoring

Mobile parameter setting, monitoring and recording of systems and processes with the IO-Link Bluetooth adapter.

Parameter setting

Easy and fast parameter setting with the moneo configure software and IO-Link master.

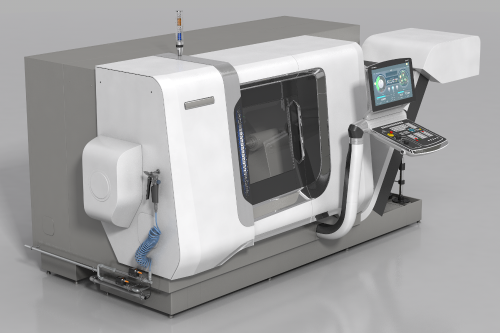

Transform your data into information

With our moneo IIoT platform you can easily configure your sensors and masters and seamlessly collect your machine and sensor data. These data can be visualised, analysed and monitored on dashboards. moneo informs you in case of process deviations and alerts you in good time.

Improve your machine availability, ensure your process quality and optimise your energy consumption.

Generate knowledge from information and make predictions

Reliable monitoring of fluctuating process parameters such as temperature, flow and vibration is one of the biggest challenges.

With the intelligent calculation of dynamic expectation ranges and the automatic adjustment of limit values, anomalies in critical systems and processes can be detected at an early stage and production reliability can be significantly increased. This is made possible by the moneo Industrial AI Assistant from ifm.

The fingerprint of every machine

Every industrial plant has a unique signature - its own “fingerprint”:

- General monitoring rules are therefore often not applicable

- Monitoring rules must be customisable, simple, precise and flexible

Since environmental conditions and utilisation may vary, monitoring must be based on the historical data of the respective system.

Success stories

Find out how ifm has helped customers to optimise their energy consumption.