- Programmable edge controller

- Setup and support

- Software and support videos

Programmable edge controller: Support tools

Software

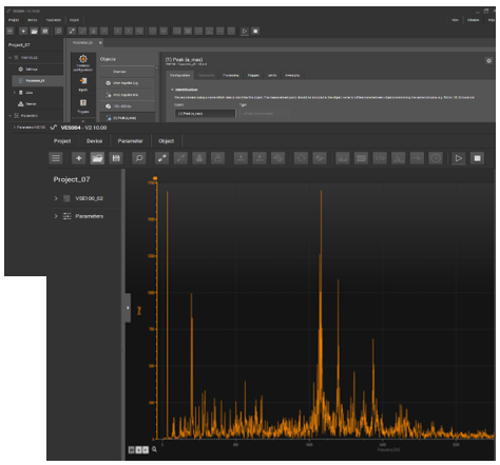

The VSE system is supported with our VES004 vibration software available free of charge from the download tab of the VSE datasheet. Using the VES004, you can

- Configure monitoring measurements

- Convert raw signal

- Analyze time wave form

- Analyze spectrum

- Gain access to the onboard measurement trend history. A typical installation provides an estimated 1 - 2 years of history.

The VSE is also supported through our software developers' kit with preconfigured APIs.

More details can be found below on this page. You can also visit our wiring and grounding guide or FAQs page. Should you need additional support with your vibration sensor, feel free to contact our service center at 800-441-8246 and speak to one of our Application Engineers.

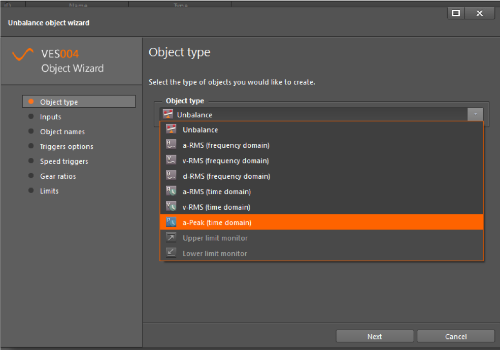

Diagnostic objects

The VES004 software configuration wizard comes preloaded with the most common vibration diagnostic objects to make initial set up easy for the novice. It is also flexible, however, for the more advanced user.

Preformatted configuration tools

The image below is a screen shot of the software wizard. It shows the preformatted configuration tools.

| Unbalance | a-RMS (Frequency domain) | v-RMS (Frequency domain) | d-RMS (Frequency domain) |

|

Monitoring 1x rotation speed is a key indicator for rotating equipment. Issues such as unbalance and misalignment are detected at the rotational frequency.

Machine use examples include:

|

Widely used for acceleration monitor of friction, a-RMS is ideal for detecting mechanical rubbing issues. When used in the frequency domain, the specific frequency range can be targeting with either a broad or a narrow operating band.

Machine use examples include:

|

Widely used for velocity monitor of fatigue, v-RMS is ideal for evaluating mechanical stress such as bending. When used in the frequency domain, the specific frequency range can be targeting with either a broad or a narrow operating band.

Machine use examples include:

|

Traditional measurement of displacement. It is often used for evaluating force at lower frequencies.

Machine use examples include:

|

| a-RMS (Time domain) | v-RMS (Time domain) | a-Peak (Time domain) | |

|

Real-time broad band average acceleration indicating the amount of mechanical energy loss.

Machine use examples include:

|

Real-time broad band average velocity indicating the rate of mechanical energy loss.

Machine use examples include:

|

Real-time broad band indicator of impacts and transient events.

Machine use examples include:

|

Preformatted configuration for rolling element analysis

Bearing fault frequencies are well defined based on the geometry and rotating speed of the bearing in question. The VES004 configuration wizard contains a database of common bearings. When one of these bearings are selected, the fault frequencies are automatically entered into the wizard.

If the bearing cannot be found in the database, the fault frequencies can be calculated based on the bearing geometry and manually entered into the wizard.