P|Prox displacement sensor: Extreme precision measurement for all metals

The IxP precision proximity sensor (P|Prox) family performs the work of a traditional displacement sensor at a fraction of the price in industries such as automotive, factory automation, food & beverage, machine tools, and metalworking.

The state-of-the-art technology enables reliable operation even when exposed to high magnetic fields. The P|Prox proximity sensor, with excellent repeatability, ensures process stability and improves product quality by measuring absolute distance values between the active sensing face and a metallic target directly in pure digital form.

The inductance change is measured and converted into an absolute distance value in the microcontroller without A/D conversion losses. This allows the sensor to provide sub-micron resolution. Accuracy and repeatability remain constant regardless of the target metals.

| Improve process stability and product quality | Reduce total cost of ownership | Simplify complexity | ||

|---|---|---|---|---|

|

|

|

Traditional analog sensor

P|Prox displacement sensor with IO-Link

Accuracy and repeatability vary

- Factors such as thermal noise, signal attenuation, temperature, and other influences affect negatively affect analog signals.

- Degradation of analog signals lead to toss of information and reduced measurement accuracy.

State-of-the-art technology provides sub-micron accuracy and repeatability

- P|Prox measures the distance to the target and directly converts this measurement into a digital distance value within its microchip.

- Minute changes in distance can be measured and signaled. No internal conversion losses provide consistent accuracy and repeatability.

- Low temperature drift.

Time-consuming adjustments, calibraion, and manual scaling

- Applications requiing high resolution measurements often require time-consuming on-site calibration.

- Mechanical fine adjustments using spacers is usually performed after the sensor is installed.

- Analog signal is proportional to the measured distance and manual scaling is generally required.

Plug-and-Work solution

- Since the output is absolute distance in mm, no manual scaling is required.

- Default calibration is done with aluminum.

- Standard performance, acceptible most applications, is achieved with other metals such as steel, and stainless steel

- For specialty applications such as detection of small objects, calibration can be done in seconds.

One sensor for one type of metal

- Traditionally, to achieve high accuracy, the application is target-dependent and the sensor is calibrated for one type of metal.

- For other metals, a new sensor custom calibration is required.

One sensor for ALL metals

- No reduction in range, and accuracy and resolution of distance measurement are constant with all metals.

- Simplifies the integration and reduces inventory complexity.

No additional diagnostics

- Traditional inductive sensors only output discrete or analog signals that are susceptible to noise interferences.

- Connection requires long home run cables or direct connections, often with hundreds of wire terminations.

- Information on sensor health and application strength is not available.

Unlock the power of IO-Link

- Information such as real-time alerts and reactions, device temperature, and other device diagnostics are available.

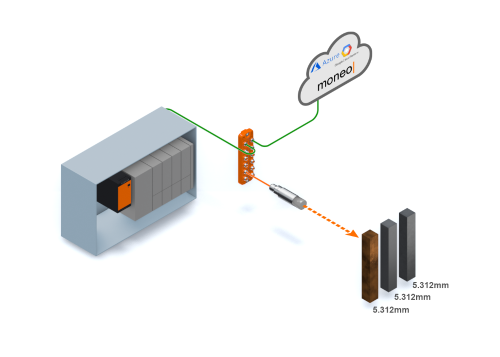

- P|Prox connects to an IO-Link master via an industry standard M12 A-coded cordset.