- Conductivity – a new approach

- Technology

Technology

Conductivity is a measure of a medium’s ability to conduct an electrical current. It is influenced by the number of free ions (like salts, acids and bases) in the medium as well as the temperature of the medium. The more free ions, the higher the conductivity. Typically, a conductivity sensor consists of two metal plates that come in contact with the medium. A voltage is applied across the two electrodes creating a current in the medium. The positively charged ions (cations) move to the negatively charged electrode while the negatively charged ions (anions) move to the positively charged electrode. The more free ions in the medium, the higher the current flow and therefore, the higher the conductivity.

SI units of measure for conductivity is Siemens per meter (S/m) and the derivations -- µS/cm and mS/cm. The chart below provides conductivity values for a few common fluids.

There are two types of conductivity measurement technologies – conductive (sometimes called galvanic or contacting) and inductive. The choice of which to use depends on the fluid conductivity, the corrosiveness of the liquid and the amount of suspended solids.

Conductive (aka galvanic or contacting) conductivity sensors (LDL1xx)

ifm's conductive conductivity sensor has two metal electrodes, like other contacting conductivity sensors. The difference with our design is that the sensor housing and surrounding metal pipe serves as one electrode and the metallic sensor tip is the second electrode. When a voltage is applied, a current flows from the tip through the medium to the housing.

With this design, there is no need to specify a cell constant, which is based on the electrode geometry.

Inductive (toroidal) conductivity sensors (LDL2xx)

An inductive conductivity sensor consists of two wire-wound metal coils encased in a plastic body (ifm products use PEEK). One coil, the transmission coil, induces a voltage in the medium, which, in turn causes an alternating current. This current induces a voltage in the second or receiving coil, which is proportional to the conductivity of the medium.

Inductive conductivity measurement has several benefits:

- High corrosion resistance of the PEEK tip

- Immunity to solids in the fluid, so long as the toroid opening does not clog

- Unaffected by very highly conductive media

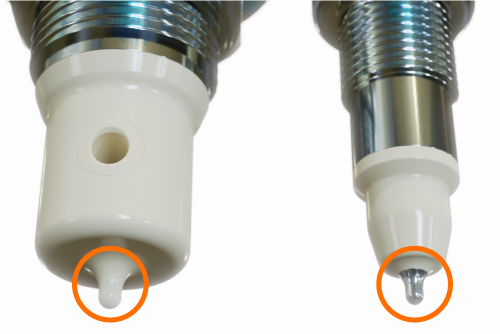

Machined PEEK tip eliminates number one cause of mechanical failure

Cracked tips are common with overmolded (PEEK over metal) designs where thermal expansion causes the PEEK to fatigue and crack after continuous termperature cycling common in CIP applications.

The all-PEEK machined tip design provides uniform thermal expansion, which eliminates stress points and potential failure, increasing your machine availability.

The long probe of the LDL201 also uses new manufacturing methods to increase probe integrity. ifm has developed a production technique to weld the end cap onto the probe. This process creates a stronger probe shaft and allows for higher precision assembly.

|

|

LDL200 / LDL210 (left) and LDL201 (right)

Influence of temperature

Temperature has a significant influence on media conductivity – approximately 1 – 5% per °C. All conductivity sensors include a built-in temperature sensor to compensate the measurement as media temperature changes.

Location of temperature sensors in LDL200 (left) and LDL100 (right)

The chart below illustrates the difference between a compensated and uncompensated conductivity measurement. Without compensation (black line), conductivity increases as temperature increases. With compensation (orange line), the mesaurement remains stable and more repeatable, providing better process control. More information on the temperature compensation and how to adjust it can be found on the Calibration webpage.

Uncompensated measurement (black line) vs. compensated measurement (orange line)

Other features of the LDL sensors

Cord grips and terminal chambers are sources of ingress. This is often a weak point for instruments installed in washdown environments. The LDL family reduces failures by providing an all-in-one transmitter rated IP68 / IP69K. It consists of a one-piece stainless steel housing and machined PEEK measuring tip with no terminal chambers or cable cord grips.

All LDL conductivity units come factory calibrated and ready to use out of the box. Factory Calibration Certificates can be downloaded at no cost from our website with the sensor serial number.

Using IO-Link, the sensors can also be field calibrated against a standard or reference solution using the Calibration Gain (CGA) parameter.

The LDL family with one-piece construction and industry standard M12 electrical connections