- Conductivity – a new approach

- IO-Link benefits

IO-Link benefits

With IO-Link, the LDL family can provide:

- Conductivity and temperature value over a single wire

- High measurement resolution without scaling

- On-the-fly recipe changes and device adjustment

- Current device status

- Operating hours histogram

- Internal memory for min and max conductivity / temperature

- Automatic device replacement

Using IO-Link, the resolution of the conductivity value is the same throughout the measuring range. This is especially important when using the inductive (toroidal) version. A typical CIP process uses chemicals with high conductivity and rinse water with low conductivity. When using an analog output, the signal is spread out over a greater range, reducing the ability to detect small changes in conductivity. This can lead to residual amounts of chemicals going undetected in rinse water or products.

|

Measuring range (µS/cm) |

PLC analog input card (12 bit) |

IO-Link * |

|---|---|---|

| 0...500 | 1 µS/cm | 1 µS/cm |

| 0...5,000 | 2 µS/cm | |

| 0...15,000 | 4 µS/cm | |

| 0...100,000 | 25 µS/cm | |

| 0...500,000 | 122 µS/cm | |

| 0...1,000,000 | 244 µS/cm |

* LDL100 measuring range is limited to 15,000 µS/cm

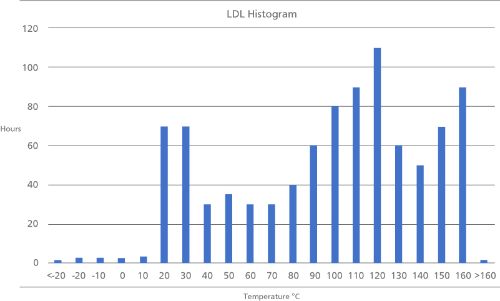

The LDL uses internal memory for edge processing of operating hours at temperature in the form of a histogram. This data provides a temperature profile over the life of the sensor in operation, and this “life history” can be a key tool in managing maintenance and quality assurance.