Rotary encoders convert rotational motion into digital signals

Rotary encoders are essential components in modern manufacturing and production processes, converting rotational motion into precise digital signals. These devices accurately determine linear distance, speed, angular displacement, and the direction of rotation. With a variety of applications, from height determination in lifts to spindle adjustments and speed detection in motors, rotary encoders ensure precise positioning and movement control. Their robust design, especially those utilizing magnetic technology, offers high resolution and durability, making them ideal for use in environments prone to impact and vibration.

Incremental encoders

Incremental encoders generate a specific number of pulses as the shaft makes a complete revolution. The more pulses per revolution, the finer the resolution of the encoder.

- Speed and angle detection during one revolution

- Pulse signal output

- Evaluation unit required

- No position traceability in case of power failure

Absolute encoders

Absolute encoders provide a unique numerical value for each angular position of the shaft. They are used in applications requiring highly accurate information on distance, speed, direction and absolute position.

- Absolute single-turn encoders provide traceability for a single revolution even when unpowered.

- Absolute multi-turn encoders provide absolute position over several revolutions even when unpowered.

Safety-rated absolute encoders

Using standard absolute encoder technology, the TÜV-certified safety encoder ensures reliable protection for vehicles and their surroundings. It is ideal for automatically moved or steered vehicles or superstructures, such as municipal vehicles, automated guided vehicles (AGVs) in logistics, and autonomous mobile robots (AMRs) in mining and harbor operations.

- Two redundant microprocessors deliever speed and position in real time.

- CANopen safety and SIL2/PLd ratings.

| Incremental | Incremental with IO-Link | Absolute single-turn | Absolute multi-turn | Absolute multi-turn with IO-Link | |

|---|---|---|---|---|---|

| Speed | |||||

| Resolution | |||||

| Revolutions | 1 | 1 | 1 | Infinite | Infinite |

| Position values | Relative | Absolute | Absolute | Absolute | Absolute |

| IO-Link enabled | |||||

| Positon memory after power loss | |||||

| Fieldbus compatibility | |||||

| Noise immunity | |||||

| Settings required |

Key: = ideal,

= caution

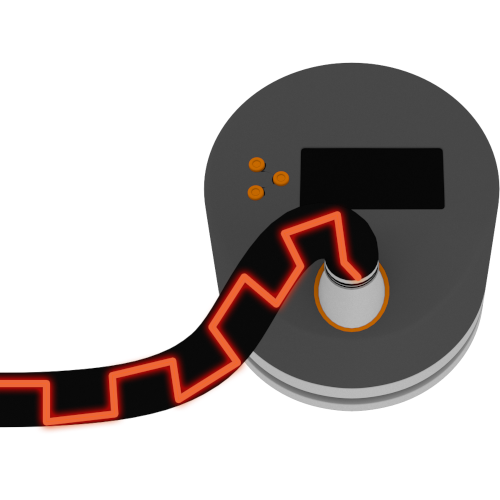

Traditional optical encoders are susceptible to damage from impact.

ifm encoders use magnetic technology and are more robust, not easily damaged by impact or vibration. Embedded IO-Link technology provides process transparency.

Magnetic technology - ifm

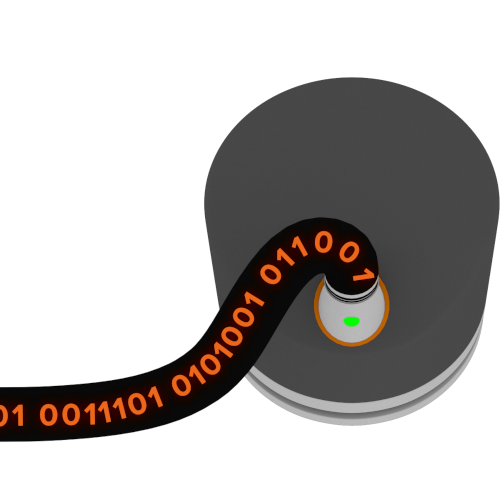

Magnetic encoders use Hall-effect sensors to detect rotary movements. The sensors detect the orientation of a permanent magnet attached to the shaft. A microprocessor then calculates the angle of rotation of the shaft from the sensor signals.

- High resolution and accuracy but smaller package and lower price point

- Fewer components for more robust solution

- Programmable resolution and output

- Variants available with IO-Link for process transparency

1 = Magnet, 2 = Hall sensor, 3 = Wiegand wire

Optical technology

Through-beam sensors emit light through the slots which are etched onto a coated glass disc. Pulses are generated as the beams are broken.

- High resolution and accuracy but difficult and expensive to manufacture

- Multiple parts, including glass disc, are prone to breaking in high shock and vibration applications

- Fixed resolution and output