- Vision sensors by application

- Technology

- Pixel counter / blob sensor

Pixel counter / blob sensor

Identify objects with variable features

The O2V vision sensor analyzes objects based on area, relative size, roundness, and contrast variation. View the animation below.

ifm’s 2D industrial imaging sensors can solve a variety of error-proofing and inspection applications throughout the manufacturing process. The compact CMOS sensors provide reliable performance in production control. Our product line includes three sensor families: the contour / pattern matching sensors, the pixel counter / blob tool sensors and the 1D / 2D code readers. The technology is somewhat similar among the three families, but for simplicity, we will document each separately. The following pertains to the contour / pattern matching sensors.

The power of a vision system with the simplicity of a sensor

ifm 2D vision sensors bridge the gap between sensor clusters and vision systems.

Challenge:

Sensor clusters

Sensor clusters are the least expensive option, but cause problems when multiple devices are used for error-proofing. Additional challenges:

- Complex wiring

- Multiple mounting brackets

- Time-consuming installation

Challenge:

Vision systems

Visions systems offer high performance but are complex and often require vision specialists. Additional challenges:

- Additional computer processing power

- External lighting

- Integration that increases costs

The best of both worlds

ifm’s CMOS vision sensors provide the simplicity of a standard sensor and the high performance of a vision system.

- Eliminates the added maintenance needed for sensor clusters

- Provides a reliable alternative to high-end vision systems

- Price-to-performance ratio allows the sensor to be used throughout a plant for error-proofing applications

Pixel counter

The pixel counter, also known as the object inspection sensor, is used for objects with variable features. Instead of a defined contour, the sensor evaluates objects based on area, relative size, roundness, etc. Additionally, grey-scale values can be used to determine full / empty conditions and contrast variations.

A dark brown spot is detected on the metal when the part is welded together properly. The absence of this mark could lead to a part failure. The weld spot does not have a consistent shape or contour to detect. This makes the pixel counter / blob tool ideal for this application.

Like the contour sensor, this product includes an image sensor, evaluation electronics and integrated lighting in a robust die-cast metal housing that withstands harsh industrial environments. Objects are reliably detected and precisely evaluated with the sensor’s fast image capture and powerful algorithms.

Working principle

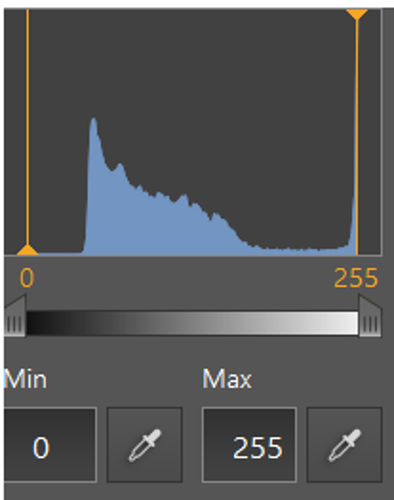

The sensor finds areas based on a defined level of pixel brightness. This can be adjusted in the configuration software to obtain the best area of interest.

For the reference image shown, note the level of detail in the areas that can be achieved when adjusting the brightness. This is easily configured during set up using a grey-scale histogram. If the level is too high, you probably see too many details. If the level is too low, you probably do not see enough details.

Select the optimum solution for your application

ifm offers products with different lensing – standard, wide angle and zoom (telephoto). To help you choose the right version for your application, consult the chart below.

Getting started with the 2D sensors

A standard 8-pin M12 cordset is used for digital I/O and power using the wiring diagram shown below. Be sure to verify the pinout of the cable you are using since wire colors are not the same for all 8-pin cables. An Ethernet cable (M12 / RJ45) and PC are required to configure the sensor.

The default IP address of the pixel counter is 192.168.0.59. Make sure your PC is set to the same domain but with different last three numbers. For example, 192.168.0.111. Note: if you are unable to connect to your sensor, most likely your IP address is not set properly.