- Laser sensors by type

- Technology overview

Technology overview - laser sensors

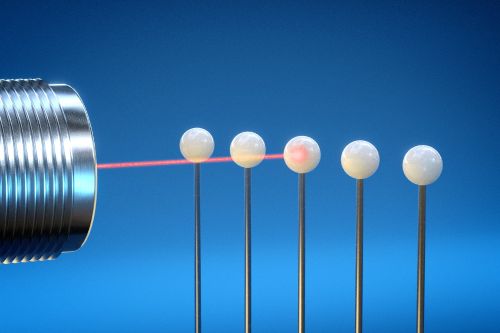

With the exception of using a laser light source, standard laser sensors operate the same as photoelectric sensors using visible red or infrared light sources. This technology overview specifically relates to laser sensors. Information on basic photoelectric technology can be found at the photoelectric sensors overview.

A laser sensor is a great choice for applications where a small target must be detected. Objects as small as 0.8 mm diameter can be detected with laser through beam sensors. Additionally, standard laser sensors work well in applications requiring a very precise switch point. Differences as small as 0.5 mm between the target and background can be reliably detected using certain laser sensors.

Advantages:

- Ability to detect small targets at long ranges

- Small light spot allows for precise switch points

- Bright red visible beam can be used as a set-up aid

Disadvantages:

- Laser LEDs are generally more expensive than standard visible red or infrared LEDs

There are several classes of laser light. ifm sensors use either Class 1 or Class 2 visible red laser light sources. Details on the safety of laser light sources can be found at the Laser Institute of America (www.lia.org) and the Occupational Safety and Health Administration (www.osha.gov).

PMD time-of-flight technology

Many of ifm’s laser sensors use PMD time-of-flight to calculate distance due to a phase shift in the light waves. Light waves propagate from the laser light source. When the light bounces off the target, the phase pattern shifts and the shift is directly proportional to the distance.

ifm’s OGD, O1D, O5D and OID laser distance sensors all use this technology.