Eliminate unplanned downtime in automotive CNC operations

Predictive maintenance solution prevents CNC spindle failures

This automotive component manufacturer faced unplanned downtime in critical bottleneck machining centers. Grease leaks or overpacking in the spindles led to overheating, causing premature spindle bearing wear and damage resulting in equipment failure.

To address this, ifm partnered with the company to identify critical machines and implement a proactive maintenance solution. During the analysis phase, ifm conducted a failure mode and root cause study along with a kinematic study of the machines. This engineering consultation led to the development of an automated vibration and process analytics system, enabling real-time visualization and alarm notifications to detect potential issues early.

Results

- Increase in visibility of critical process values allowing for actionable insights resulting from ifm’s predictive maintenance solution

- Improvement in equipment availability - the 8 hours of previously unplanned downtime was replaced with a scheduled 3 hours of planned maintenance

- Reduction in scrap rate

- Savings of $1.1 million annually or $37,000 per incident were achieved due to downtime and scrap reduction

- ROI in system satisfied in 2 months

The challenge

- Grease leakage and over-packing of CNC spindles go undetected, causing overheating and leading to premature equipment failure

- Bottleneck machining centers downtime causes process disruptions and high repair costs

- Maintenance is reactive instead of scheduled as failures cannot be predicted

- A system is required that integrates seamlessly with existing IT architecture

The solution

- TS temperature and VV vibration/temperature sensors were used to monitor spindle bearing temperature, helping detect grease leakage or overpacking early

- PN pressure sensors were used to monitor and confirm correct pressure limits for the pneumatic and hydraulic clamping of parts

- LK level sensors were installed in both the spindle lube and hydraulic lube tanks to accurately detect lube levels

- SA flow sensors were used to monitor coolant flow throughout the spindles and to verify that seals and housings were clear of coolant and debris

- VSE vibration monitor with edge analytics and VV vibration/temperature sensor were installed to predict early spindle bearing wear or damage, spindle or tool crash, unbalanced conditions and machine component defects

- I/O blocks and cordsets with IO-Link technology were used to transmit sensor data to the PLC

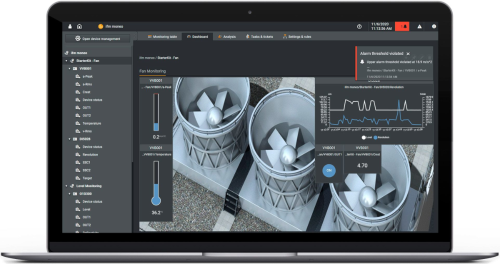

- All sensor signals were continuously checked and recorded using ifm’s moneo IIoT software platform, which was configured to send alert emails to the maintenance team and to the operating dashboard

Technologies

Explore the underlying technologies that power this solution.

RTDs were placed throughout the process to identify rising temperature caused by excessive friction or other effects.

VVB3 sensors continuously detect vibration in three axes and measure surface temperature on non-rotating components. This data helps assess machine condition in real time.

PN pressure sensors provide reliable pressure monitoring for both hydraulic and pneumatic systems.

LK level sensors offer accurate detection of coolant, lubricant, and hydraulic oil levels. They are ideal for maintaining proper lubrication and fluid management in industrial systems.

SA flow sensors reliably detect flow rate of water, oil, glycol and air. Outputs include flow velocity, flow rate, and temperature, ensuring efficient fluid control and leak detection.

VSE diagnostic edge controllers evaluate up to 4 dynamic vibration signals, offering seamless integration into automation systems for real-time asset health monitoring.

IO-Link technology is fundamental in real time monitoring and is embedded in ifm sensors. This technology allows the sensors to communicate the health and condition data via ethernet for processing. IO-Link communication provides fully digital data, resulting in higher quality measurements eliminating analog conversions.

moneo|software contains drag and drop dashboards used to implement real-time monitoring of sensor values. These visuals can be programmed to show the progression and end-of-life data for multiple tools or alert of parameter critical values.

Gain a competitive edge with ifm

To learn more about ifm sensor systems and asset reliability products to improve the performance of your complete operation contact your local ifm Sales Engineer or email cs.us@ifm.com.

Jump to: