- IO-Link modules

- Technology

- Status information in process-data

Status information in process data

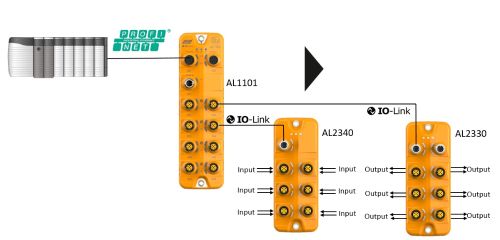

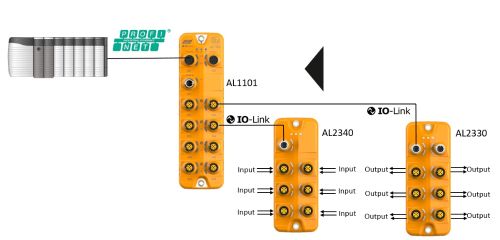

Data communication from the master to the output module:

The PLC can control each output in each output module which is connected to the IO-Link master. The master sends out 4 bytes of cyclic data. The output will be switched when the corresponding bit in the process data is "1".

Response of the output module to the master:

In the same manner, the PLC can read status information from each module. In byte 4, the module can detect undervoltage, short circuit and the general status of the module.

- In case of overload or short circuit in one of the two supply voltages, all error bits of this "side" are set to "1"

If the total current of one side is too high, the unit switches off the overloaded side and disables this side. To enable the outputs of this side again, there are 3 methods:

Method A:

- Set process data output byte 0 and byte 2 to 0 via IO-Link

- The left side is enabled again

- Set process data output byte 1 and byte 3 to 0 via IO-Link

- The right side is enabled again

Method B:

- Disconnect the module and connect it again

- Both sides are enabled

Method C:

After removing the source of the short circuit, the user can send IO-Link commands, that release L and R side latch:

- 208 Reset L side latch

- 209 Reset R side latch

In case of undervoltage on the left or right side, the UVL or UVR bit is indicating this failure.

The "status" information in byte 6 is a copy of the variable [Device Status] in the process data channel:

(0) Device is OK

(1) Maintenance required

(2) Out of specification

(3) Functional check

(4) Failure