- 3D object recognition

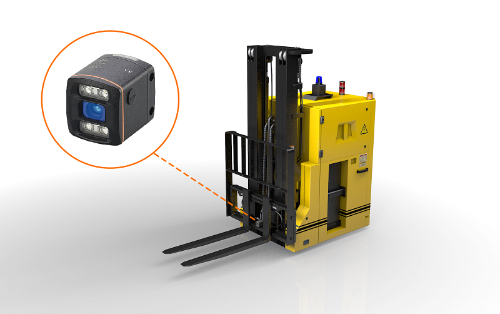

- Pallet Detection System (PDS)

- Integration of the PDS

Integration of the PDS

The key to a successful implementation of any solution is a firm understanding of all requirements. PDS is no different. This section provides all details required to ensure successful implementation of PDS. This includes:

- Mounting position:

Where and how the camera should be mounted to the vehicle. - Wiring:

How to wire the PDS solution (power supply/communication). - Software interface:

How the PDS solution is connected to the vehicle controller. - Detectable pallet types:

What types of pallets can be detected with the standard PDS solution.

Following these steps will ensure a successful PDS implementation.

The PDS solution

Mounting position:

Inclination

Mounting height

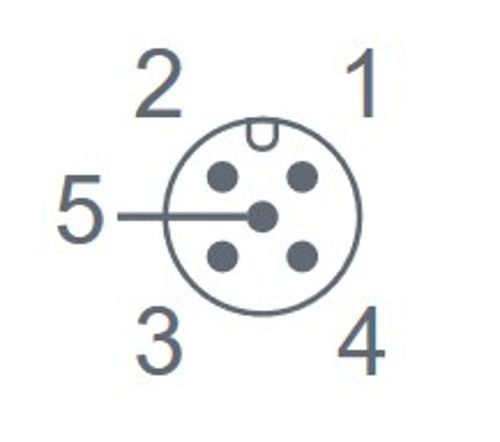

Wiring

The PDS is integrated in the O3D Camera. This camera requires a 24V DC power supply and communicates via Ethernet. The wiring of both interfaces is shown in the following image:

Connector: 1 x M12 Electrical connection: Process connection |

Connector: 1 x M12 Electrical connection: Ethernet |

|---|---|

| 1. U+ | 1. TD+ |

| 2. Trigger input | 2. RD+ |

| 3. GND | 3. TD- |

| 4. Switching output 1 ready | 4. RD- |

| 5. Switching output 1 cascading |

Note: The camera requires 2.4 A peak current during image capture.

Detectable pallet types

The PDS is designed to detect pallets with two pallet pockets. A distinction is made between "block" and "stringer" pallets.

The PDS can be used to detect the following 2-pocket pallet geometries/types:

Wood, block |

Wood, stringer |

Plywood, stringer |

Double-sided |

Reversible |

2-way |

GMA 4-way |

Single-face, stringer |

CHEP |

PECO |

Plastic |

Nestable, plastic |

IGPS |