- Valve position sensors by application

- Technology overview

Technology overview

MVQ smart valve sensor

ifm’s MVQ smart valve sensor uses magnetic technology to detect the position of quarter-turn valves. It provides a continuous feedback signal and the valve’s position is retained even after a power outage.

Features of the MVQ

Quarter-turn valve position sensors

Quarter-turn valves and pneumatic actuators are used for process control in industrial automation. Feedback systems indicate the open and closed position of the valve. ifm’s feedback system is compatible with all actuators using ISO NAMUR VDE 3845 standard mounting. This common standard exactly defines where the threaded holes for mounting the sensor must be located by the actuator manufacturer.

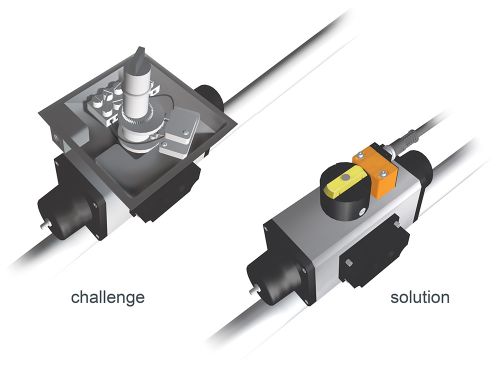

Challenge: Mechanical switchboxes have moving parts that can stick and break.

Solution: ifm’s sensor and target puck provide non-contact valve position feedback.

ifm’s IN sensors use standard inductive technology to provide non-contact detection of metal targets. A typical inductive sensor contains a ferrite core surrounded by a coil of wire to form an inductive circuit. An IN sensor incorporates two ferrite coils. These coils are positioned vertically inside the housing. The rotating puck, which is mounted on the actuator stem, contains two stainless steel targets positioned on the side of the puck, 90° apart, at different heights.

As the valve opens, the puck rotates, moving one of the targets in front of one ferrite coil. The coil senses the target and provides a positive signal of valve-open position.

When the valve closes, the puck rotates and moves the second target in from of the second ferrite coil. The coil senses the target and indicates a positive valve-closed position.

ifm offers these products in AC and DC voltage, with local solenoid switching, for hazardous locations and with integrated AS-i capability.

Selecting a puck kit

Select a puck kit according to the dimensions of your ISO Namur actuator. The X and Y dimensions show the position of the mounting holes and the Z dimension is the height of the actuator stem.

ifm makes two different types of target pucks. The basic puck is for standard 90 degree applications. The adjustable puck is for actuators with different target positions. The packages for higher stems include a spacer to raise the height of the sensor to match the targets on the puck.

Rising stem valve sensors

ifm’s IX sensor is an innovative solution for indicating the position of linear valves. The sensor continuously detects the position of rising stem valves with a stroke up to 80 mm. The sensor is mounted on top of the valve stem and “open”, “closed” and an intermediate point (e.g., seat lift) are configured using pushbuttons. The sensor reliably detects the stem position at a resolution of 0.2 mm.

The sensor uses 16 air coils that are multiplexed together to create a linear sensing field. Each coil is connected to microprocessor-controlled electronics. As the valve stem enters into the coil arrangement, the coils detect the stem one after the other. The position of the stem is then compared with the established switch points. The integrated LED display and switching outputs provide valve position feedback.

16 coils detect the location of the stem with 0.2mm resolution

For double seat valves, the IX sensor detects the open, closed and seat lift cleaning positions. For single seat valves, it detects the open and closed positoins with an additional output for seal contact wear.