Case study | Automated plato calculation during fermentation

How to increase efficiency with automated fermentation monitoring

Fermentation during the brewing process converts the glucose in the wort into the beer we enjoy. During this process, yeasts convert the sugars in the wort into ethanol, which reduces the amount of dissolved sugars and changes the density of the media. Specific gravity is the measurement most commonly used in brewing and is a measurement of the dissolved sugar content in an aqueous solution.

| Visualize plato values | Reliable, real-time data | Increase efficiency |

Results

-

Increased process efficiency due to precise plato calculations and temperature monitoring

-

Reduced risk of inaccurate measurements performed with a densitometer, refractometer, or graduated cylinder

-

Reduced wort scrap by quickly correcting stalled fermentation

-

Increased visibility of fermentation progress inside all tanks in industrial software

-

Redirected hours of labor from manual tank checks to value-added work

The challenge

Many craft breweries start as small operations, where manual processes seem cost-effective and easiest to implement. As a brewery grows, it may run into challenges where those operational inefficiencies are difficult to scale up with production. It may appear that components on a tank are more expensive, when in reality they save labor costs and provide more reliable product quality from batch to batch. Fermentation is an incredibly important part of the brewing process, where yeast converts the sugars in the wort into alcohol. As the yeast converts the sucrose, the specific density of the liquid decreases in a predictable pattern that correlates to the alcohol content of the final product. Specific gravity is the most commonly used measurement in the brewing process, capturing the dissolved sugar content left in an aqueous solution.

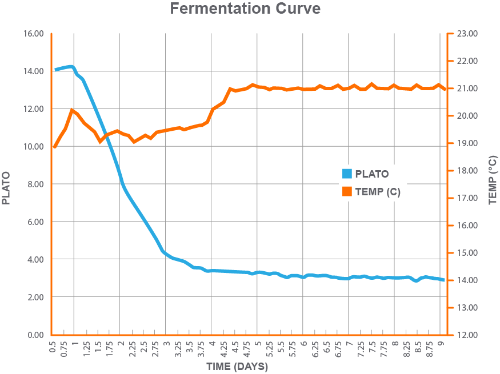

Plato values are often calculated by an employee manually checking the progression of fermentation by pulling a sample from the tank to measure with a handheld instrument, such as a portable refractometer. These instruments measure the current sugar content remaining in the beer to capture changes in the density of the liquid. The sample measurements are then entered into a computer and a fermentation curve is plotted on a graph to track the conversion from sugar to alcohol in the liquid at specific points in time.

The disadvantages of manual plato measurements are:

- Risk of entering inaccurate values

- Lack of visibility to fermentation progress between measurement points

- Inaccurate values due to variation in the sugar content of the wort in different areas of the tank

The solution - why ifm?

The fermentation process in beermaking turns the wort from brewing into beer. Typically, yeast is pitched into the chilled wort which starts the fermentation process. During the fermentation process yeast consume the dissolved sugar in the wort and convert it into ethanol alcohol and cardon dioxide. The amount dissolved fermentable sugars is what determines the amount of alcohol that will be in the final beer. This is typically referred to Original Gravity (OG) and Final Gravity (FG) of the beer, where the original higher density wort is converted to a lower density beer as the sugars are converted into alcohol.

The density measurement can be used to calculate Specific Gravity (γ ) or degrees Plato (°P) using the equations below:

Visit the “Density measurement” application for more information on hydrostatic pressure and density.

Implementation

Pressure sensor installation

Using two high resolution PI17 pressure sensors from ifm at a fixed height apart from each other, we can continuously monitor density of the beer in real-time.

An additional benefit of using two pressure sensors to calculate plato values is receiving a more accurate understanding of how fermentation is progressing throughout the entire tank. Density over a larger fluid column provides a more aggregate measurement. It also allows you to know when fermentation is complete, so you can move to the next step of production.

This increases process efficiency by saving you time and potentially increasing brewing capacity of your equipment.

Plato monitoring software

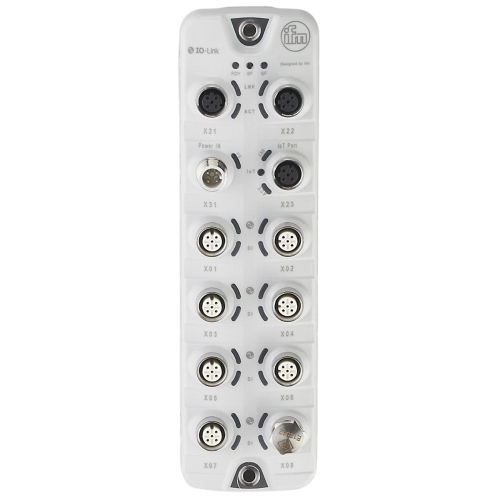

Instead of performing these calculations manually, ifm IO-Link masters enable you to send the pressure data to any higher level software system. To provide a comprehensive solution, ifm now offers a pre-programmed display controller that can receive the temperature and differential pressure data from the sensors and automatically calculate the Plato measurement in real-time. This reduces the need to source specialized programming knowledge. Simply input the height of the tank and the controller will populate the Plato curve on the screen.

Continuously monitoring the changes in specific gravity during fermentation provides valuable process data. This can be used to ensure fermentation is behaving normally or identify problems during fermentation. The brewmaster can then make adjustments to the batch when possible. Increased access to this data leads to improved process and product quality when compared to the lack of visibility that results when using manual or handheld methods.

The ifm solution offers another advantage. With consistent monitoring, it is possible to ensure consistency and quality between batches. Repeated fermentation curves contribute to producing a consistent golden batch every time.

Technologies

Explore the underlying technologies that power this solution.

IO-Link technology is the foundation of scalable automation solutions. This technology allows the sensors to communicate the fermentation data via ethernet for processing. IO-Link communication provides fully digital data, resulting in higher quality measurements that eliminate analog conversions. With IO-Link, you can have confidence in your temperature and pressure measurements.

ifm PI17 series sanitary pressure sensors provide the necessary resolution to monitor fermentation within a tank. The underlying sensing technology, the embedded IO-Link communication, and the sanitary housing are all important features for fermentation tanks and other brewing equipment.

Aftering installing the ifm PI pressure sensors, this preprogrammed display controller easily visualizes Plato calculations in real-time. The CR series can be used for machine control or simple visualization and monitoring.

Explore the display controller

Gain a competitive edge

Automated fermentation monitoring contributes to increased process efficiency. Breweries of any size benefit from the increased accuracy when monitoring the fermentation process and logging historical data for future use. Whether craft breweries monitor each batch closely for slight variations in flavor or commercial breweries monitor hundreds of fermentation tanks simultaneously, automated plato calculations can benefit operations of all sizes. It all starts with one IO-Link master, which allows for flexible solutions that are both cost-effective and easy to scale.

Data generated from automated processes offer valuable insights for further improvements. Breweries can leverage this data to fine-tune their operations, increase efficiency, reduce costs, and continually improve batch quality.