OGD laser sensors: Simple solution for error-proofing

Error proofing, also known as mistake-proofing or poka-yoke, is a highly effective technique for preventing errors and mistakes in a variety of processes. Production errors are inevitable; however, the sooner the error is caught, the less expensive it is to correct. Defects often go undetected until the end of a manufacturing process or even at a final customer's site.

As depicted in the chart below, the cost of an error at the manufacturing cell level is low. However, if a defective part reaches an end customer, the cost to correct grows exponentially.

The OGD laser distance sensor provides robust and reliable distance measurement for your error-proofing applications.

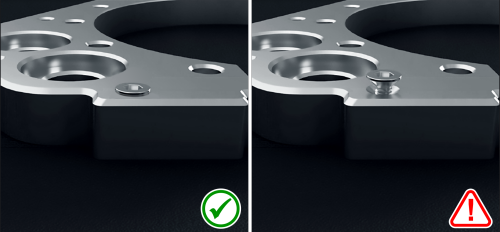

Object orientation

Missing component

Correct installation

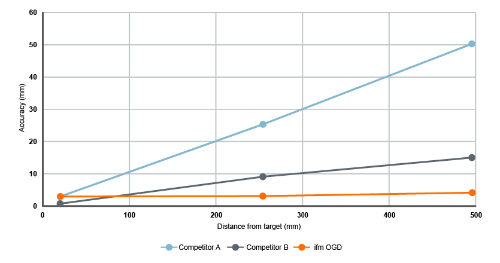

Superior accuracy at an affordable price

The accuracy of the OGD's time-of-flight technology compares favorably relative to competitors' CMOS technology, especially given the price point.

As the range increases, the OGD continues to deliver high accuracy allowing one sensor to be used in a variety of applications up to 500 mm range.

The interactive tool below can help you determine how the OGD sensor will perform in your application. To use the tool:

- Click on the operating mode your application requires - Fine, Standard, or Fast.

- Enter the sensing distance for your application.

- Read the accuracy for both black and white targets.