Programmable vibration edge controllers

The VSE diagnostic electronics is a programmable unit that evaluates up to 4 dynamic vibration signals, offering seamless integration into automation systems for real-time asset health monitoring. With built-in edge computing, it handles monitoring tasks in both time and frequency domains, communicating within milliseconds using configurable condition parameters.

Cabinet module

VSE1xx (IP20)

Field device

VSE9xx (IP67)

- Supports up to 4 acceleration sensors for continuous characteristic value calculation

- Accepts auxiliary signals (e.g., speed, pressure, temperature) via analog or digital inputs for reliable machine condition monitoring

- Provides configurable outputs for pre-alarm and main alarm notifications

- Ensures secure separation between automation and IT networks

- Enables bidirectional communication via Ethernet TCP/IP (e.g., OPC UA) and fieldbus interfaces (Profinet, Modbus TCP, EtherCAT, EtherNet/IP).

- Features integrated history memory with a real-time clock for data logging

- Compatible with all common acceleration sensors for flexible integration

- VSE9: Designed with a robust IP67 housing for decentralized use

- VSE9: Allows quick, error-free installation with standard M12 connectors

Fault mode digital twin modeling & real-time monitoring

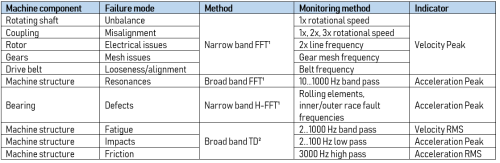

Edge computing enables measurements and calculations at the point of use, converting raw data into narrow band root cause measurements. This creates a digital twin of the equipment’s fault mode kinematics, with continuous real-time updates in milliseconds. By eliminating bandwidth issues, ifm’s VSE system simplifies digital modeling, using broad and narrow band vibration indicators to monitor machine components for maintenance and production process quality.

The chart below shows a typical configuration for vibration monitoring of rotating equipment.

FFT¹ = Frequency domain; TD² = Time domain

Edge computing technology effectively manages your system network resources. ifm’s VSE edge controller can convert raw accelerometer measurements (25k points/sec) into usable information (up to 104 specific measurements). This compression is required to transmit data over system networks. Minimizing impact on network resources, computing power, data storage, and evaluation labor is vital for any large-scale rollout.

Integrate edge controllers in a wide variety of ways. Once configured, easily connect their switching outputs to PLC inputs, stack lights, or any other switching or analog control system. The VSE system is also fully compatible with Industrial and PC-based Ethernet networks such as EtherNet/IP, PROFINET, Modbus, and TCP/IP.