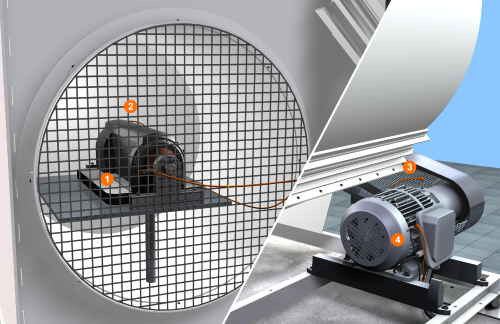

Ducted fan monitoring

Fans are used in virtually every manufacturing plant and typically, they are located out of sight of normal daily traffic. Remote monitoring for wear on bearings, shaft or blade unbalance, etc. can reduce unplanned downtime events and improve your overall plant efficiency.

Fan drive shaft monitoring

- Accelerometer monitors bearing frequencies providing alerts of damaged or worn bearings that cause mechanical stress and unbalance conditions.

Fan blade assembly monitoring

- Accelerometer monitors forces to detect build up on blades and prevent out-of-balance conditions.

Record and time-stamp events

- Capture operational usage to pinpoint operating stresses that can cause flow blockage or starvation issues.

Fan drive shaft monitoring

- Accelerometer monitors driven end bearings for proper lubrication and operation.

Fan drive belt monitoring

- Accelerometer monitors drive belts for proper tension and operating condition.

Drive motor monitoring

- Accelerometer monitors driven end bearings for proper lubrication and operation.

- Accelerometer monitors drive belts for proper tension and alignment for operation condition.

Drive motor monitoring

- Monitor motor temperature for excessive heat due to overload, mechanical friction, rotor or bearings.

- Accelerometer monitors motor cooling fan and bearings for unbalance and wear.

- Accelerometer monitors misalignment, loose foot and other mechanical looseness issues.