Verifiable quality assurance for sanitary applications

ifm manufactures process sensors that are used to measure flow rates, flow velocities or the conductivity of media. In practical tests in a CIP installation, the sensors are checked regarding their function, precision and manufacturing quality.

The initial situation: Limited monitoring via a PLC

The CIP installation can be operated with different media, pressures and temperatures in order to test the sensors as close as possible to the customer applications. A common industrial controller is used to control the system, which means that monitoring by means of sensors can only be implemented to a limited extent.

Goal of the project: Data-based plant monitoring without integration of the PLC

By means of the moneo platform, a comprehensive solution for plant monitoring was to be implemented which also offers the possibility of accessing historical data and analyzing it in depth. moneo is easily scalable. As a first step, conductivity and temperature were to be monitored. Further monitoring includes measuring parameters such as level, flow and pressure.

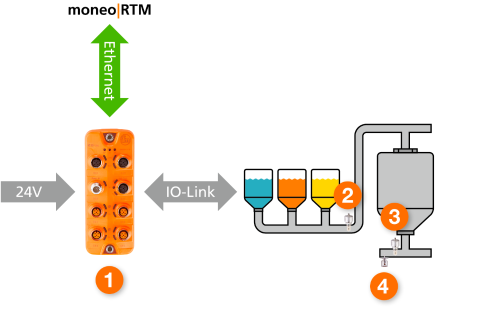

Implementation: moneo RTM meets IO-Link

Due to the existing powerful IT infrastructure, moneo was installed on a central server of ifm prover gmbh and the moneo RTM application was licensed. The sensor data is transmitted to moneo via an IO-Link master connected by VLAN.

The result: Data-driven process optimization

The comprehensive and continuous data acquisition enables a permanently accurate analysis of the CIP process. The information gained can be used to optimize processes where necessary and thus increase and maintain quality in the long term with efficient use of resources. Thanks to the storage of the data history, the efficiency of the process optimization can also be traced in the long term and made sustainable. In addition, the software solution used offers the user every freedom to design displays and evaluation logics individually according to their requirements. Thanks to the user-friendly design, this can be done very intuitively.

Bottom line: Value added services of CIP monitoring

- Adaptation to individual customer application with one software platform

- Monitoring and analysis of the cleaning process WITHOUT intervention in the PLC

- Permanent data recording and database storage

- Redundant system for additional process safeguarding

- Identification of savings potential

- Calculated values: conversion of sensor values into process-relevant information using data modelling – calculated values

- Integrated alarm management: fast reaction to changing process parameters through integrated alarm management

System structure

- IO-Link master (AL1350)

- Conductivity sensor in the inlet

- Medium temperature (LDL200) in the outlet

- Medium temperature (TCC501) in the outlet

Dashboard

The dashboard provides the user with an overview of the relevant process values for the CIP installation. They can create a customized dashboard using drag and drop and integrate plant graphics to better visualize their measurement points. In this way, they receive a clear representation of the system status across all sensors.

- Conductivity (LDL200) in the inlet

- Conductivity (LDL200) in the outlet

- Difference of the conductance values (calculated value)

- Medium temperature of the conductivity sensor (LDL200) in the inlet

- Medium temperature in the outlet of the temperature (TCC501) and conductivity sensor (LDL200)

Analysis

The analysis uses historical data and compares process values from different points in time. For example, it can be measured how long it took for the conductivity in the inlet and outlet to reach the same level. This supports the machine operator in optimizing the process. Expensive rinsing processes with acids and alkalis, for example, can be optimized.

- Display of relevant sensor values in the analysis chart

- Visualization of the time for the individual cleaning processes

- Correlation of process values of inlet and outlet

- Conclusion about deposits in the system

Temperature is a decisive factor in cleaning, but also a cost driver. Every degree that can be saved brings a significant saving over the year. In the analysis, temperature curves of the sensors can be conveniently evaluated.

- Temperature of the conductivity sensor (LDL200) in the inlet

- Temperature of the conductivity sensor (LDL200) in the outlet

Tasks & tickets: start/stop thresholds

The machine operator can easily monitor the system via thresholds. Individual thresholds can be defined for each process value. In the concrete example, the process value of the current difference between the conductivity in the inlet and outlet is monitored. If the difference becomes too large, the machine operator receives a warning or alarm message.

- Integrated alarm function for limit value monitoring

- Automated ticket generation in case of alarm

- Configurable tickets with defined recipients

- Alarm escalation strategies

- Early detection of damage and malfunctions

- A predefined wizard can be used to configure an alarm strategy

- The customer can manage the generated alarm ticket at any time before closing

- Comments can be added to the ticket, such as the cause of the error or a maintenance strategy

- The time of the threshold violation can be viewed in the data analysis via an analysis button

Calculated values

Using this function, process values can be linked and used for calculations. In the concrete example, the calculated value enables a fast detection of the conductivity difference at the inflow and outflow.

- Conductivity inflow

- Conductivity outflow

- Calculation of the absolute difference of the two input values

- Result of the calculation