- E-Mobility

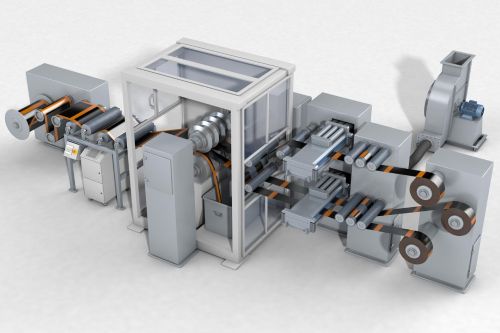

- Battery cell | Electrode production

Optimising quality in electrode manufacturing

The lithium-ion battery is the core element and currently the most expensive component of an electric car. This is due in part to the non-renewable raw materials that are used, which are already rare, but also the scalability of production. Battery manufacturers must therefore optimise their processes wherever possible. The increased efficiency together with fewer rejects while quality remains consistent play a key role in this.

ifm offers a variety of solutions for this, consisting of hardware and software. In this way you can digitise your production proactively to ensure quality.

Your Advantages with Digitised Automation

| Increased system availability thanks to error detection at an early stage. | |

| Easy condition monitoring thanks to clear data preparation. | |

| Central alarm system allows for fast response in case of emergency. |